Currently, 3D printed personalized prostheses are widely used in clinical orthopedics, such as 3D printed artificial acetabular prostheses, scapula prostheses, pelvic prostheses, thoracolumbar artificial vertebrae, and personalized prostheses. 3D printed implants of different shapes have also helped doctors solve difficult and serious treatment problems such as spinal tumors and severe trauma.

Recently, according to Mohou.com, a patient underwent vertebral body replacement surgery and a purely locally produced “self-stabilizing” 3D printed titanium alloy microporous structure artificial vertebral body was implanted. It is reported that titanium alloy powder, the base material of the artificial vertebral body, is produced domestically, and the 3D printing equipment used to produce the vertebral body was independently developed by China. The implantation of this “self-stabilizing” 3D printed titanium alloy microporous structure artificial vertebral body marks that in the field of orthopedic applications of 3D printing technology, our country not only has the ability to design and independently develop related innovative products, but also has domestic equipment and The ability to produce materials enables comprehensive process innovation from original design to product development and manufacturing.

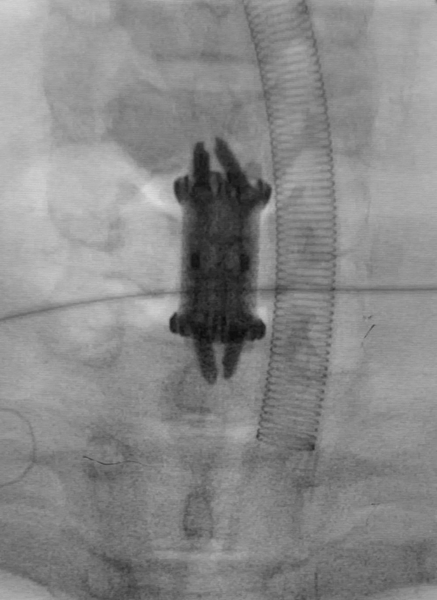

△After surgery

Paving the way for localization of 3D printed bones

Vertebral body replacement is used for patients with cervical spondylosis, cervical spine tumors and other patients who require removal of the vertebral body for treatment. At present, the repair technology of cervical vertebral body resection at home and abroad generally adopts the method of titanium mesh plus titanium plate and screws, i.e. that once the vertebral body is removed, a cylindrical titanium mesh structure is placed in the area of the bone defect. after the vertebral body is removed, then the vertebral body is removed. A titanium plate is placed in front of the titanium mesh, and the upper and lower ends of the titanium plate are fixed on the adjacent vertebral bodies using screws. Since the device requires assembly, the fixing force is somewhat reduced. At the same time, the fixed titanium plate covers the front and rear ends of the vertebral body during surgery, and the front of the cervical spine constitutes the esophagus. The protruding part of the titanium plate can easily press the esophagus.

“The “self-stabilizing” 3D printed titanium alloy microporous structure artificial vertebral body improved this problem by removing the titanium plate that causes the patient to feel compressed, directly combining the screws with the vertebral body and by placing the implant on the surface. of the cervical spine. Flush, reaching “zero notch”. » As the surgeon who implanted the 3D printed titanium alloy “self-stabilizing” artificial vertebral body with microporous structure, Peking University. Liu Zhongjun, Director of the Institute of Spine Surgery of the Third Hospital, Professor and Chief Physician of the Department of Orthopedics, and Head of the Expert Group of the Medical Device Standardization Technical Unit for Manufacturing Technology medical additive, showed the artificial vertebral body model and said that preliminary studies confirmed that 3D printing “self-stabilizing” The biomechanical properties of the artificial vertebral body with a microporous structure made of titanium alloy are better than the titanium fillers used in the past and the surgery is simpler. He introduced that this “self-stabilizing” 3D printed titanium alloy microporous structure artificial vertebral body has been on the domestic market for more than a year and the feedback from medical units has been very good and it will be gradually introduced into the international market. in the future.

In a context where more than 90% of high-end medical devices depend on imports, locating 3D printed artificial vertebrae is not easy. As the leader of the national key research and development project “Key technologies and clinical applications of additive manufacturing of personalized orthopedic prostheses”, Liu Zhongjun frankly said that this 3D printed titanium alloy microporous structure artificial vertebral body “self -stabilizer” is “a bit…understood.”

At first, Liu Zhongjun wanted to use 3D printing to make an artificial pivot. But the language of doctors and engineers is not on the same “channel”. Engineers cannot understand specialized medical terminology and anatomical names; it is also difficult for doctors to understand the professional language of computer science and engineering.

“Later, I used plasticine to knead a model of the vertebral body of the axis and gave it to the technicians, and asked them to print it first, said Liu Zhongjun , then the two sides communicated and modified the model several times, building on that.” such a “stupid method”, Liu Zhongjun’s research team finally 3D printed an artificial pivot.

△3D printed self-stabilizing artificial vertebral body implanted during surgery

3D printing and orthopedic applications “get along well”

3D printing, also known as additive manufacturing technology, is a revolutionary advancement in manufacturing technology. In recent years, this technology from the industrial field has also made considerable contributions to the medical field – producing medical models, assistive devices, prosthetics, surgical guidance devices, etc. Of course, there are also 3D printed bones.

Liu Zhongjun said that 3D printing technology has unique application advantages in the field of orthopedics. “On the one hand, CT images of bone tissue can be easily converted into 3D printed digital files; on the other hand, bone anatomy is a complex and hard tissue, with a relatively constant shape, which is exactly the characteristic of 3D printing technology products.

At first, 3D printing technology was mainly used in the field of orthopedics to produce bone models, which facilitated medical education, clinical diagnosis and treatment, and doctor-patient communication. Around 2010, with the advent of metal 3D printers, it became possible to produce metal materials for human internal plants using 3D printing technology. Taking spine surgery as an example, 3D printing technology can not only create surgical operating guides to improve the accuracy of intraoperative punctures or screw insertions, but also can produce titanium alloy implants beneficial to repair and reconstruction of bone structure and function.

“At present, 3D printed orthopedic internal fixations mainly use titanium alloy. Titanium alloy is also one of the most commonly used metal materials for 3D printing. Titanium alloy has good compatibility with human tissues and will not cause immune rejection such as allergies, “The application of titanium alloys in the field of orthopedics is very mature,” Liu said. Zhongjun. At the same time, he said that titanium alloy vertebral bodies can also be designed with a microporous structure like a sponge, so that bone cells from adjacent normal vertebral bodies in the human body can grow into them and eventually fuse together. , significantly improving firmness. . “This is a very important achievement in the medical field,” he said.

Before 3D printing technology was applied to orthopedics, researchers and technicians were also conducting research on the design, application and processing of personalized bone and joint prostheses. However, traditional standardized prostheses cannot be reconstructed or function poorly, and their difficult design and long manufacturing time significantly limit their clinical application.

“However, 3D printing can customize the complex human bones that patients need, providing orthopedic surgery with the opportunity to move from the ‘cut to fit’ model to that of ‘tailoring’ the treatment model, to obtain truly “personalized” and “precision” treatment. said.

Currently, 3D printed personalized prostheses are widely used in clinical orthopedics, such as 3D printed artificial acetabular prostheses, scapula prostheses, pelvic prostheses, thoracolumbar artificial vertebrae, and personalized prostheses. 3D printed implants of different shapes have also helped doctors solve difficult and serious treatment problems such as spinal tumors and severe trauma.

Independent innovation along the chain takes a long time to succeed

In the future, there is still huge room for development in the application of 3D printing in orthopedics. Our country’s scientific researchers and enterprises should further develop their innovation capabilities and promote independent innovation throughout the chain in this field to benefit more patients. Liu Zhongjun said that there are currently competent research and development teams studying the use of magnesium metal to produce 3D printed human internal plants. “Magnesium alloys have good performance in the repair and reconstruction of bone structure and function. At the same time, they also have certain anti-infection capabilities and can reduce related infectious complications.”

This is a direction for future material innovation in orthopedic 3D printing applications. Can better 3D printed implants be designed so that they can integrate into the patient’s bone tissue more quickly and shorten the disease treatment cycle? Can growth-promoting drugs be attached to the surface of internal plants to accelerate bone growth? Can we place slow-release drugs into the micropores of endophytes to support them and treat diseases at the same time? These are questions that deserve further consideration and research by science and technology workers.

Moreover, although 3D-printed artificial vertebral bodies have taken a crucial step toward localization, according to Liu Zhongjun, it will take a long time to achieve independent and comprehensive innovation in the field of 3D-printed artificial prostheses.

“Although my country already has the technology to independently produce 3D printed artificial vertebrae, its application scope is still limited.” Liu Zhongjun said that most 3D printing equipment and materials rely on imports, and currently, domestic 3D printing equipment and original medical materials still are. very limited.

Liu Zhongjun suggested that the state should formulate relevant policies to encourage and support the localization of 3D printing medical devices, promote clinical scientific research innovation and the integration of industry, academia and research, strengthen cooperation between institutions and businesses and achieve complete independence. in 3D printing of orthopedic application materials, design, research and development and production, innovate to benefit more patients.

“This is also an important opportunity for China’s orthopedic technology innovation to move from a follower to a leader. I hope to see a closer combination of 3D printing technology and orthopedic applications to achieve a higher level of technological autonomy and autonomy. “Liu Zhongjun said.

Source: Science and Technology Daily

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.