Orthopedic 3D Printing: Revolutionizing Knee, Hip, and Spine Implants

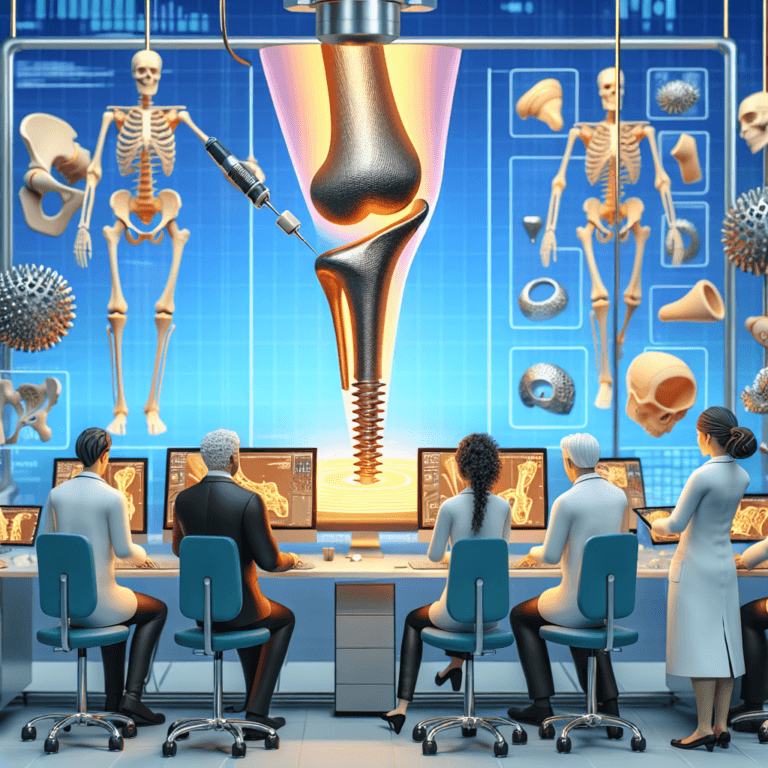

In the landscape of modern medicine, few advancements hold as much promise as 3D printing technology, particularly in the field of orthopedics. The revolutionary ability to create customized implants is changing the way knee, hip, and spine surgeries are performed, improving patient outcomes and significantly enhancing the quality of life for countless individuals. This blog post dives deep into how orthopedic 3D printing is transforming the industry through personalized solutions, improved surgical precision, and, ultimately, better patient outcomes.

The Rise of 3D Printing in Orthopedics

3D printing, also known as additive manufacturing, has gained traction in various medical fields, but its application in orthopedics has been especially noteworthy. Traditionally, orthopedic implants were mass-produced in standard sizes, which often led to complications, such as improper fit and discomfort. Thanks to advancements in 3D printing techniques and materials, surgeons can now design and produce custom implants tailored to the specific anatomy of each patient.

Customized Knee Implants: A New Standard of Care

Total knee replacement surgeries are among the most common orthopedic procedures performed today. While traditional implants can provide relief, they don’t always fit every patient optimally. With 3D printing, orthopedic surgeons can create knee implants that are perfectly shaped to fit the patient’s unique anatomy.

Advantages of 3D Printed Knee Implants:

Personalization: The standout feature of 3D printing is personalization. Pre-operative imaging, including CT and MRI scans, can be utilized to create highly accurate models of the knee joint. Surgeons can then design implants that consider factors such as bone structure, alignment, and individual activity levels.

Improved Fit and Comfort: Custom-fit knee implants can reduce the likelihood of complications such as implant loosening or malalignment. A better fit translates to improved functionality and comfort, which ultimately leads to enhanced mobility for the patient.

Reduced Surgery Time: Surgeons can reduce the duration of the operation with perfectly fitting implants. This minimization of surgical time can lead to fewer complications and a faster recovery process.

- Enhanced Longevity: 3D printed implants can also be made from advanced biomaterials that are designed to bond more effectively with surrounding bone, providing greater stability and longevity than traditional options might offer.

Hip Implants: Tailored Solutions for Improved Functionality

Hip replacements, similar to knee surgeries, often depend on the standardization of implant sizes. With 3D printing, orthopedic surgeons can provide personalized hip replacements that address individual anatomical needs.

Benefits of 3D Printed Hip Implants:

Customized Designs: Using advanced software, orthopedic surgeons can design hip implants with precise geometrical characteristics based on each patient’s unique hip morphology. This process ensures that the implant will restore the natural biomechanics of the hip joint effectively.

Enhanced Biomechanics: A well-designed implant not only fits better but also improves the overall performance of the hip joint. This enhancement allows patients to regain activities that they may have otherwise deemed impossible due to pain or limited mobility.

- Biocompatibility: Advances in biomaterials allow for the creation of implants that may reduce the risk of infection. 3D printing can utilize materials that promote bone in-growth, further enhancing implant stability and longevity.

Transformative Potential in Spinal Implants

The spine is a complex structure, and spinal surgeries often pose significant challenges due to anatomical variability. 3D printing technology offers a formidable solution, enabling the creation of customized spinal implants that cater to a wide range of spinal conditions.

Innovations in Spinal Implants via 3D Printing:

Precision Engineering: Similar to knee and hip sparing surgeries, spinal implants can be tailored to the individual patient’s anatomy, accommodating for variations in spinal curvature, size, and other factors that influence spinal alignment and functionality.

Spinal Fusion: For patients undergoing spinal fusion procedures, 3D printing can produce grafts designed to optimize bone regeneration. Personalized grafts provide better integration with the patient’s bone, enhancing healing and stability post-surgery.

- Reduction in Revision Surgeries: The intricacies of spinal anatomy mean that even a minor misalignment can lead to significant issues later on. Customized spinal implants can drastically reduce the likelihood of revision surgeries, which are not only costly but also carry additional risks.

The Role of Bioprinting: The Future of Orthopedic Implants

As 3D printing advances, so does the possibility of bioprinting—an innovative technique that potentially carries the capacity to create not just implants, but actual living tissues. This could be a game-changer in orthopedic surgery. Future research may lead to the creation of biologically active bone grafts, which encourage natural tissue regeneration, reducing dependency on artificial materials entirely.

Challenges and Considerations in Orthopedic 3D Printing

While the benefits of orthopedic 3D printing are immense, there are still several challenges that need to be addressed:

Regulatory Hurdles: The medical industry is heavily regulated, which poses challenges to new technological advancements. Ensuring that 3D printed implants meet regulatory standards for safety and efficacy is paramount.

Material Limitations: The choice of materials for 3D printing in orthopedics is still somewhat limited. Research is ongoing to develop new materials that can provide better performance in terms of strength, durability, and biocompatibility.

- Evaluating Long-term Outcomes: As this technology is still relatively new, the long-term performance of 3D printed implants is under evaluation. Ongoing studies will help ascertain reliability and longevity compared to traditional surgical options.

The Road Ahead: Integration into Clinical Practice

As orthopedics continues to embrace the benefits of 3D printing, it will be crucial for educational institutions and surgical training programs to incorporate this technology. Surgeons must be skilled in both the design process and the surgical prowess to implement these cutting-edge solutions effectively.

Conclusion: A Brighter Future for Orthopedic Patients

The introduction of 3D printing technology in orthopedics is setting the stage for a more personalized, effective approach to joint and spinal health. Improved implant fit, reduced surgery times, and enhanced biomechanical outcomes are heralding a new era where patients can look forward to longer-lasting, more functional lives following surgery.

As research progresses and technological capabilities expand, the integration of 3D printing into orthopedic practice is likely to continue evolving. With ongoing advancements, orthopedic patients can anticipate a future filled with personalized care tailored to their unique needs, transforming the journey from injury to recovery into a more successful and less painful experience.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.