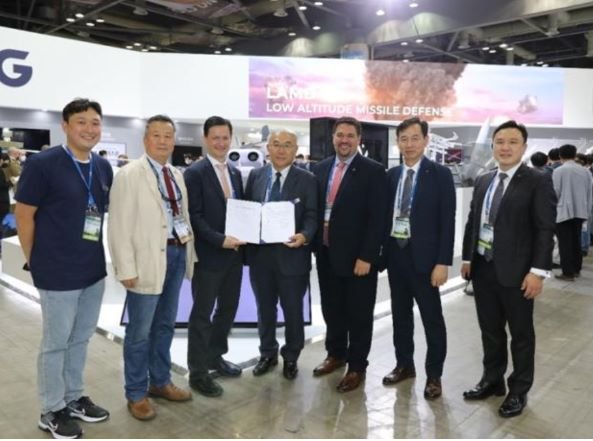

2022Year11moon,3DPrinted Antenna CompanyOptisysAlready working with Korean aerospace manufacturers and defense companiesEQUAL to Nex1Sign the agreement and Optisys Revolutionary RF Integrated Technology for Defense and Aerospace (RF) in the system.

Optisys

Optisys is a supplier of advanced antenna and radar products. Next-generation RF products make it possible to SWaP-CThe solution’s efficient capabilities enable breakthrough system and product performance. Their technology is made possible by new design processes and metal additive manufacturing for component production.Optisys can be supplied from 1 arrive 100GHz solutions ranging from flat panel power supplies and antennas to phased arrays and synthetic aperture radars, and many more in between. As part of the radiating element, the peripheral aspects of the RF aperture are also designed and fully integrated, such as filtering, combiner networks, waveguide switching, duplexing, etc.

△RF equipment

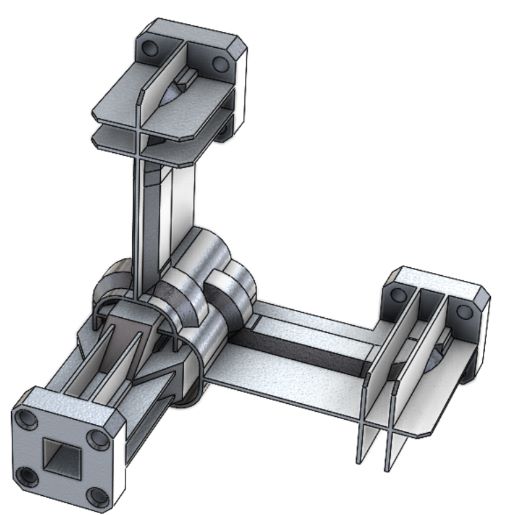

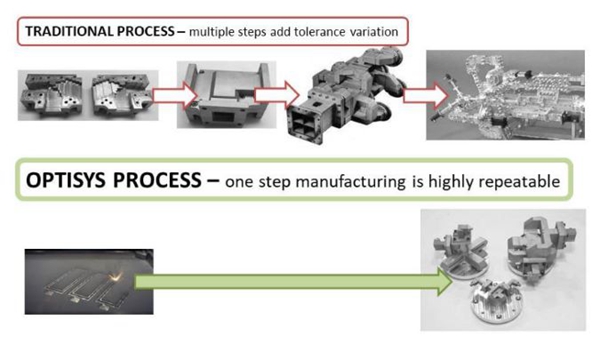

Compared with traditional production technology,Optisys Designs often take advantage of additive manufacturing technology, which allows for considerable simplification, for example by reducing multiple antenna components into a single part. Beyond that, Nikon might also be interested in the potential offered by investing to produce as many RF components in-house as possible.

Optisys Use modular design antenna assemblies to significantly reduce design costs, reduce weight, reduce size, and shorten design time and manufacturing cycles. will be the radio frequency/Electrical, mechanical, structural and thermal requirements combined into one metal 3D in the print component.

AndEQUAL to Nex1sign an agreement

Optisys It was revealed that the deal was signed last year 9 Held in Seoul2022 Signed at Korea Defense Expo 2018, professional RF solution provider will help design, develop and manufacture advanced metals 3D Print antenna systems and help EQUAL to Nex1 Lead the development of digital manufacturing technologies. The program aims to promote both metals3DCollaboration on the design and development of printed antennas established with metal3DCooperation system in the field of digital manufacturing technology related to printing. manufacturing technology.

Optisys CEO Janos Opera commented: “Additively manufactured antenna systems significantly reduce To exchange (size, weight and power), while reducing the number of parts and simplifying the supply chain. All of these reductions are key to overall system cost reduction, which also increases reliability for the defense and aerospace industry. under Optisys technology and LIG Excellence in advanced systems production, we seek to create new systems that reach new levels of efficiency and excellence. “

△Used for NRAO of 3D Printing RF Antennas Optisys design. Photo by Optisys provide.

Since 2014 For years,EQUAL to Nex1 Metals that have always counted on the defense industry 3D Printing technology. The company benefits from AM Known for promoting the development of mass production processes for lightweight, high-strength components used in radar, satellites and robotics. In the future, it is also planned to establish a defense parts and components industry.3DThe printing quality management system applies the national defense quality management process to increase production, reduce cycle times and reduce costs in the manufacturing process.

In addition, the South Korean company also participated in the national competition HE Industry Promotion Office(BY)monitoring 3D The Printing Manufacturing Innovation Demonstration Support Project, an organization established by the Korean government, is committed to supporting innovation, expansion and creating a viable environment for businesses to TIC industry. The technology can be applied to the mass production of advanced weapon systems such as guided weapons, surveillance and reconnaissance equipment, communications equipment, etc.EQUAL to Nex1 Director Chanho Kuk means metal 3D Printing technology enables miniaturization, lightweight design and maximum performance, which are requirements in the defense and aerospace sectors.Kouk underlined: “We are Optisys The signed memorandum of understanding will be an opportunity to contribute to the development of South Korea’s defense and aerospace sectors. “

USA 3D Printed Antenna Company Optisys describe AM benefits. Photo by Optisys provide.

In recent years,EQUAL to Nex1 Advanced weapons applications, such as next-generation drone defense systems, are under development and could change the paradigm of future warfare. Many of these surface-to-air guided weapons and associated electronic warfare equipment and technologies could help prevent North Korean drones and other weapons from entering the airspace.

For example,EQUAL to Nex1 are working to develop something similar to Russia’s Krasukha Korean-style electronic countermeasures. The local government promotes EQUAL to Nex1 of K-Too bad This version, once operational, could emit jamming radio waves in response to North Korea’s electronic warfare.EQUAL to Nex1 An indigenous air defense radar has also been developed and will be used by South Korean troops deployed in combat. K Used in conjunction with jammers. at present,EQUAL to Nex1 Has approx. 250 experts in electronic warfare development and production, as well as several facilities dedicated to testing electronic warfare systems. With its additive manufacturing expertise and capabilities, the company is expected to play an important role in implementing integrated solutions that efficiently connect high-performance equipment focused on electronic warfare systems.

△Effective air defense systems with indigenous technologies can deal with different types of aerial threats. Photo by EQUAL to Nex1 provide.

Optisys In the design and manufacturing of high performance metals for aerospace and defense applications 3D Antenna printing know-how is ideal for EQUAL to Nex1 and local needs.Optisys Capable of manufacturing some of the most advanced additive design components by combining multidisciplinary optimization with mass production requirements.

Recently, this RF Antenna solutions leader secures undisclosed investment from Nikon, aimed at leveraging Optisys The ability to produce high-performance printed antennas in commercial quantities. by adopting in its factoriesSLM500 technology,Optisys Now with high-tech metals AM system, ideal for producing high-strength metal parts such as those required by space and defense customers. Based on the memorandum of understanding Optisys And EQUAL to Nex1 A cooperation center, the two companies will provide quality systems to Korea and could become EQUAL to Nex1 A springboard to the global defense and aerospace markets, which are now worth more than 7000 billion dollars.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.