For spur gear manufacturers with greater manufacturing depth, it is generally best to purchase the used bevel gear kits as non-standard products. This eliminates the need for special manufacturing processes. However, in recent years, customers have become increasingly dissatisfied with the quality of externally purchased gears. These gear pairs are usually cut from older machines and are often unfinished, or simply ground to improve the contact area.

The desire to improve the quality of assembled gears often goes hand in hand with the goal of producing bevel gears in-house to reduce reliance on suppliers. However, investing in gear cutting and grinding machines alone often does not achieve the desired result.

With the performance of today’s abrasive products, a gear grinding machine can be purchased to perform the pre-machining and finishing of bevel gears on a single machine without compromising the quality of the gear pairs produced. In this case, the productivity of the deep grinding process is comparable to that of traditional mechanical cutting machine tools. The only difference is that deeply ground gears are measured against the target data and can be corrected in a closed-loop system. It is therefore not necessary to acquire the necessary knowledge to manually correct the position of the contact area.

Deep grinding of bevel gears offers a wide range of possibilities and opportunities:

01. Relatively low investment costs Relatively low investment costs

If you want to start the production of bevel gears, in the simplest case you only need a bevel gear grinding machine equipped with the KOMPASS measuring option and KOMET correction software. KLINGELNBERG can design gear pairs on-site for existing component series, eliminating the need to develop in-house expertise. If objective quality control is to be carried out outside the machine tool (e.g.: customer documentation), it is recommended to invest in a suitable measuring instrument instead of choosing the KOMPASS measuring option.

The grinding wheels and dressing rolls required to manufacture the intended gears must be stored as consumables. However, there is no need to invest in additional pre-machining machines or make large investments in cutting tools.

02. Use of simple lighting fixtures

With just a thread or clamping cap on the end of the pinion shaft, the workpiece can be clamped axially in a simple fixture using a simply designed clamping rod and the hydraulic system of the machine. The radial runout of components can be easily calibrated manually. Therefore, the mounting accuracy only needs to ensure the parallelism of the axial positioning surface. Since the forces generated during deep grinding are relatively small and there are no impact loads, only relatively small clamping forces are required to hold the workpiece in place.

03. Short response times

A key advantage of deep grinding is the ability to respond quickly to short-term needs, such as the supply of unusual spare parts or a much-needed redesign of a gear pair.

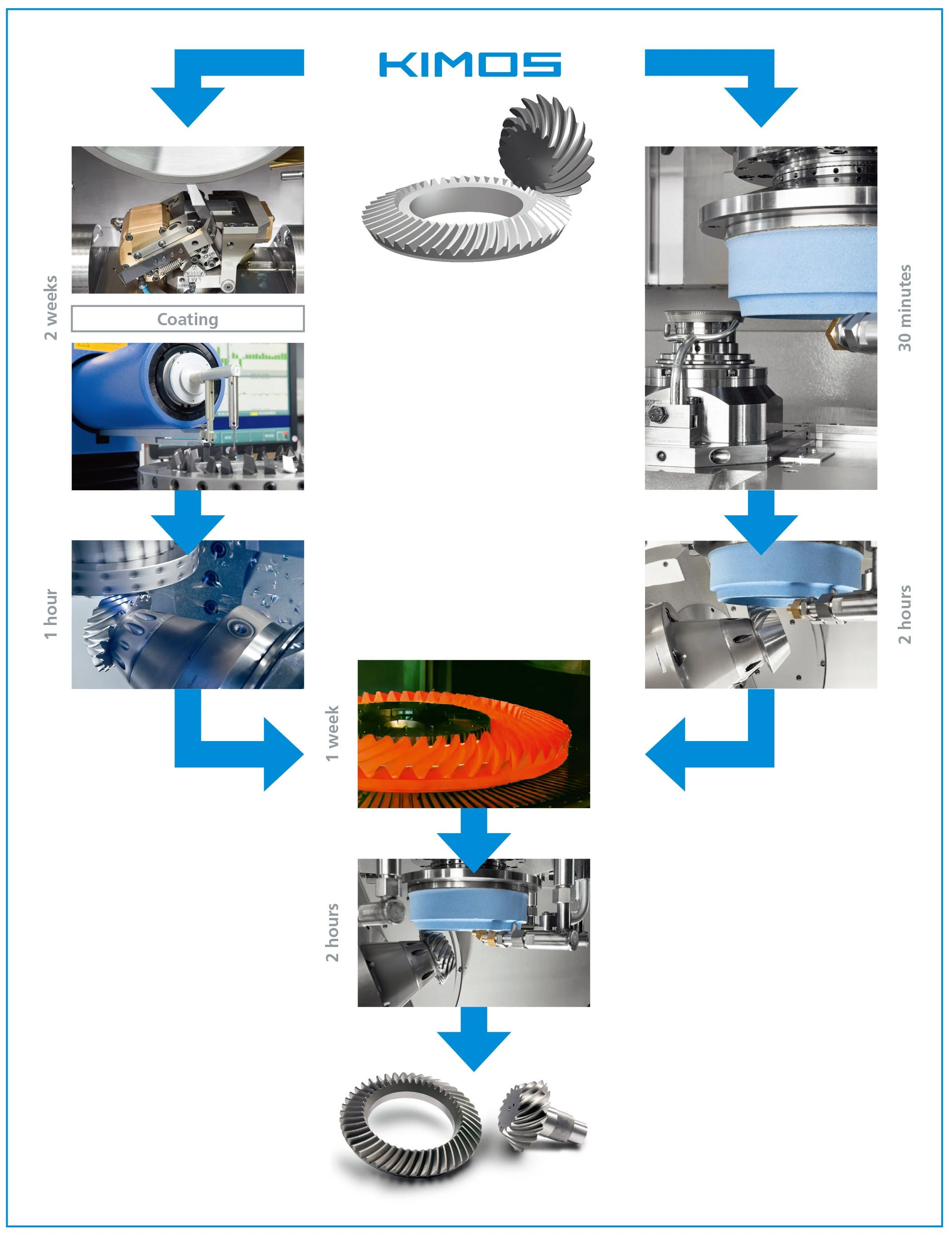

Unlike traditional pre-machining by bevel gears, deep grinding simply requires the correct wheel size and you can start working straight away without the need for a complete adjustment of the tool head or, in the worst case, to shape the tool and the coating. This saves approximately two weeks, or two-thirds of the processing time (see Figure 1). Adjusting the coolant supply requires slightly longer preparation times and machining times, but these are not significant.

Figure 1: Production cycle from bevel gear to finished gear pair

04. Process Technology Overview: Process Flow and Analysis

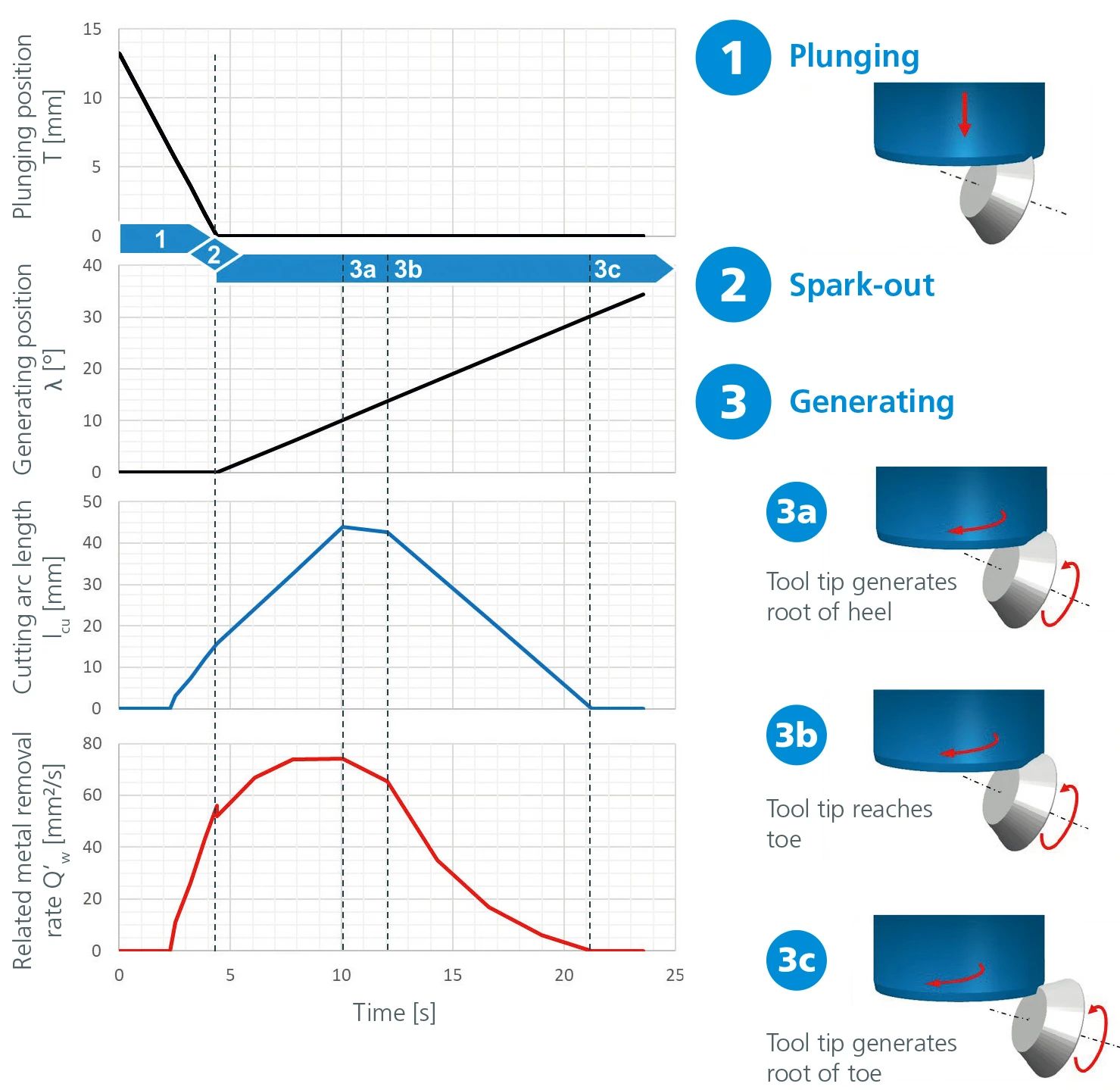

In practice, there are several options for deep grinding of the resulting components. One is to extend the length of the raceway to allow rolling in the gear. This usually starts at the root of the gear to avoid collision with the gear body or collet. However, gear rolling can cause increased load on the fillet radius of the grinding wheel, resulting in tooth profile deviations. It turns out that moving down from the large end of the gear and then expanding towards the small end (see Figure 2) is a more advantageous method. During the driving process (see Figure 2.1), the load on the wheel tooth profile is relatively uniform and approximately proportional to the volume of cut removed from the wheel. Depending on the geometry of the gear, a relatively large portion of the tooth space volume is already machined or comes into initial contact with the component near the end of the driving process, as shown in the figure.

Figure 2: Kinematics and characteristics of the tool tip

During the transition between sinking and expanding (see Figure 2.2), sudden changes in tool load often result in brief power surges, generating sparks and increasing the risk of tool damage. In the past, feed rates were often adjusted to accommodate this transition, but this limited the potential of the process. By setting a minimum priming time before the generating move begins, power spikes can be converted into short power dips, allowing for more efficient machining.

Depending on the geometry of the gear, the generation process can begin when the maximum length of the cutting arc is reached or, as shown in the figure, when the tool enters the gear. The maximum length of the cutting arc is generally achieved when the tip of the wheel reaches the root of the tooth at the large end of the workpiece (see Figures 2, 3a). However, due to rolling kinematics, the maximum load on the tool tip (calculated as metal removal rate) may occur earlier. When the tool tip reaches the tip circle of the small end of the workpiece (see Figures 2, 3b), the load drops quickly and drops to zero when the root of the small end is formed (see Figures 2, 3c ). The remaining length of the rolling path is still needed to completely form the concave tooth flank.

Depending on the performance of the grinding wheel and the material to be machined, intermediate dressing may be necessary after machining one or more tooth spaces. When machining oversized gears, it may be more beneficial to divide the material removal rate into several defined steps to reduce tool load. Large tooth pitch and tooth profile deviations can occur due to increased tool wear between tooth slots, which generally have little effect on pure pre-machining. If quality requirements are high, these deviations can be compensated for by fast finishing cycles with small feeds.

05. Optimize the process

In order to improve the depth grinding of slightly larger batches, we need to optimize the machining process. Since the cooling lubricant supply accounts for a large part of the total system energy consumption, which is largely independent of the cutting power, the energy consumption of each part can be reduced in an approximate proportion of the time machining.

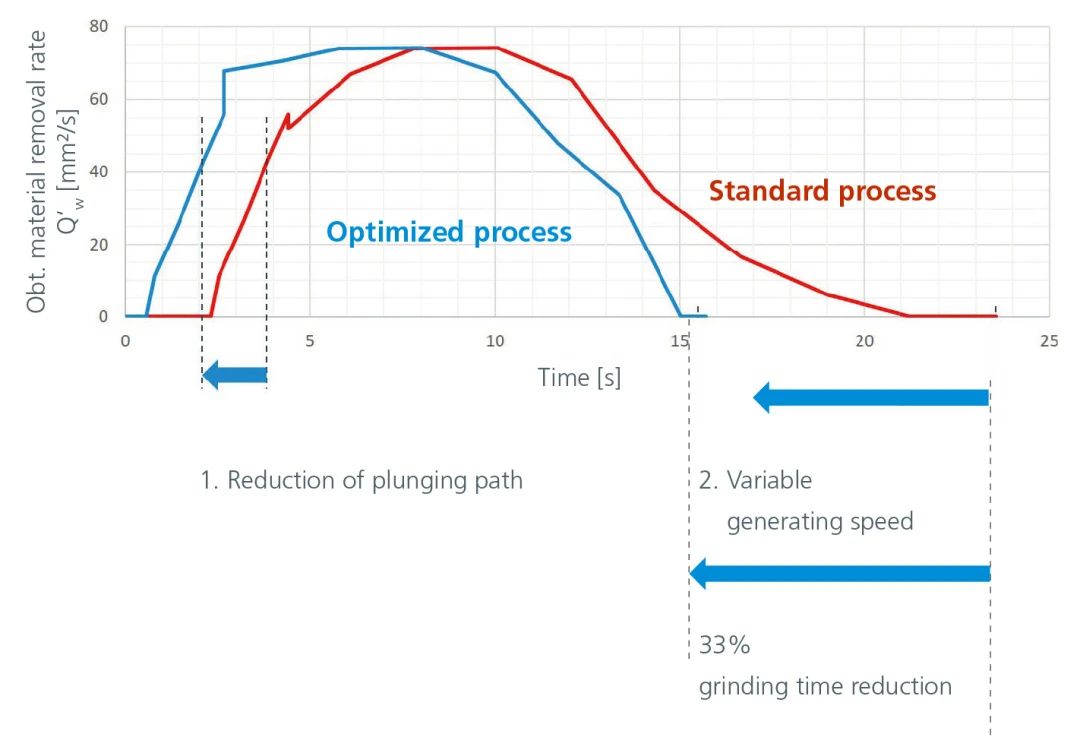

There are two ways to save processing time without increasing the maximum tool load (see Figure 3):

Figure 3: Optimize the process without increasing the maximum tool load

1. The initial depth of the sinking process can be reduced to the point where non-contact sinking in air is almost unnecessary.

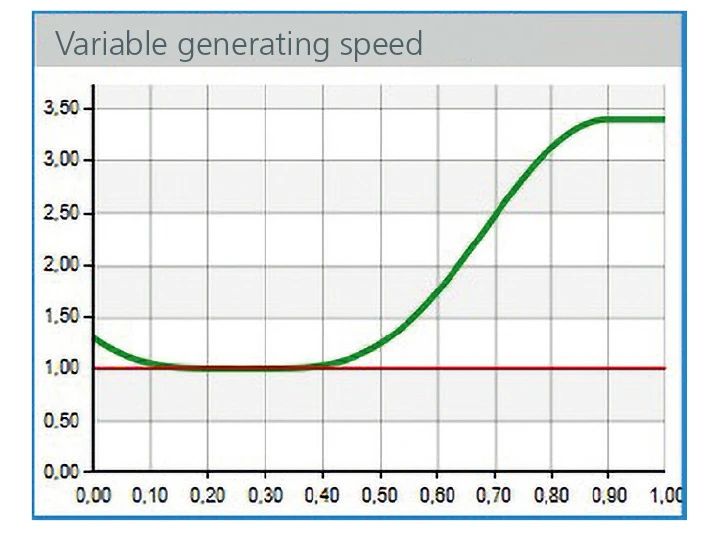

2. The speed curve along the length of the raceway can be adjusted in the KOP-G machine tool software to ensure that the material removal rate at the tool tip remains substantially constant.

These two measures save about a third of the grinding time of the gear example without overloading the tool.

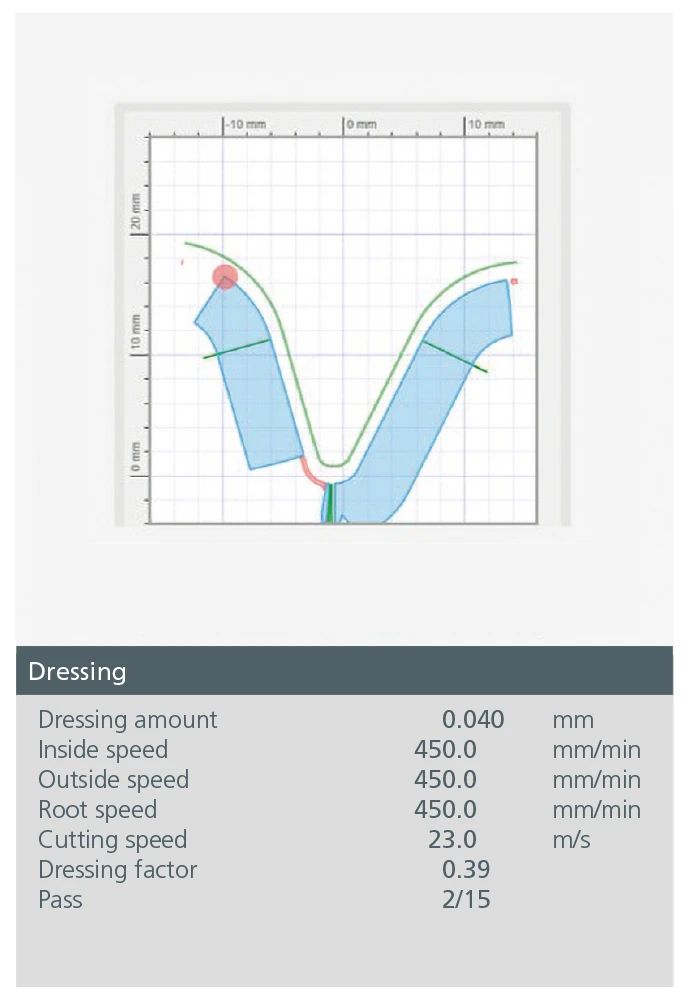

06/Dressing the grinding wheel

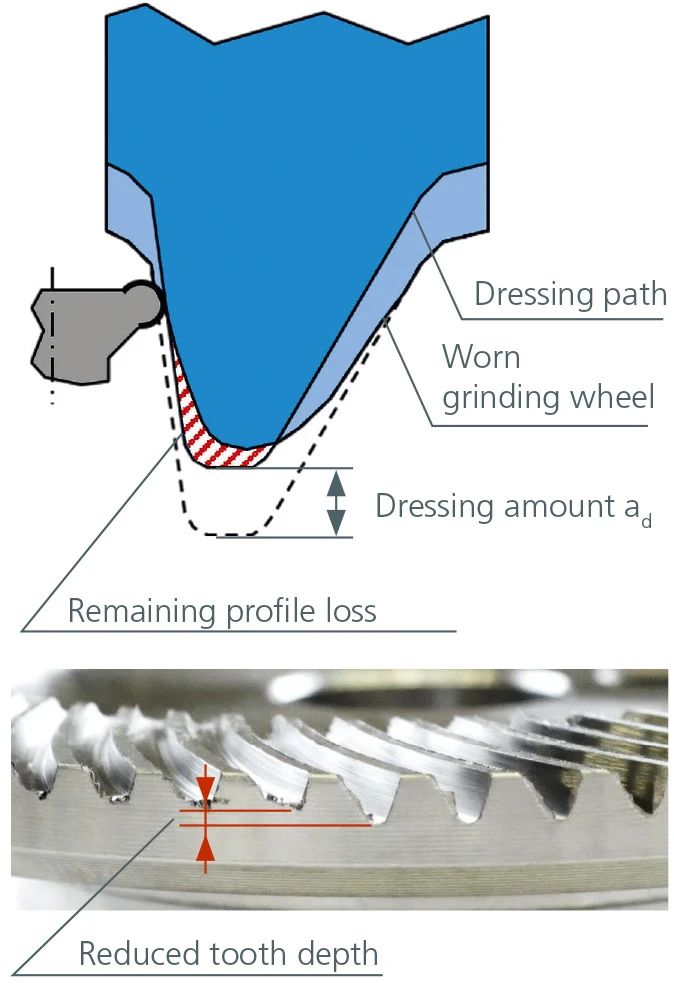

When processing specific parts, the preforming program of KOP-G machine tool software can complete the dressing of the grinding wheel tooth profile in a short time. However, it is possible for the wheel to become locally damaged during machining, usually at the tip or corner radius. This situation occurs when the amount of dressing is less than the height deviation of the tooth profile during grinding (see Figure 4). As a result, the wheel wears more after dressing and cannot produce the correct clearance geometry. This loss is usually difficult to detect with the naked eye and is only noticed when the depth of the space becomes significantly shallower. In order to restore the grinding wheel tip, several dressings are required, but there is great uncertainty in the number of dressing cycles.

Figure 4: Deviation of tooth profile during deep grinding

Figure 5: Inspecting contacts during trimming

Features a contact detection option while cutting. Although the deviation of the grinding wheel tooth profile cannot be detected immediately during gap machining, it can at least be detected during the subsequent dressing operation. This is achieved thanks to an acoustic emission sensor integrated into the dressing spindle. The machine control unit evaluates signals above the required tooth profile and thus detects tooth profile deviations (see Figure 5). This feature also minimizes dressing operations while restoring the full shape of the tooth.

07/Range of components and processing example Range of components and processing example

Deep grinding has a wide range of applications and is suitable for all gear sizes. At the lower end, the width of the tool nose is a limiting factor. If the grain size of the abrasive is fine enough, a tip width of approximately 0.3 mm can be used for grinding. Deep grinding can also be used in the higher application area of the Oerlikon G80 bevel gear grinder. However, due to the large amount of material to be removed, the processing time can reach several hours.

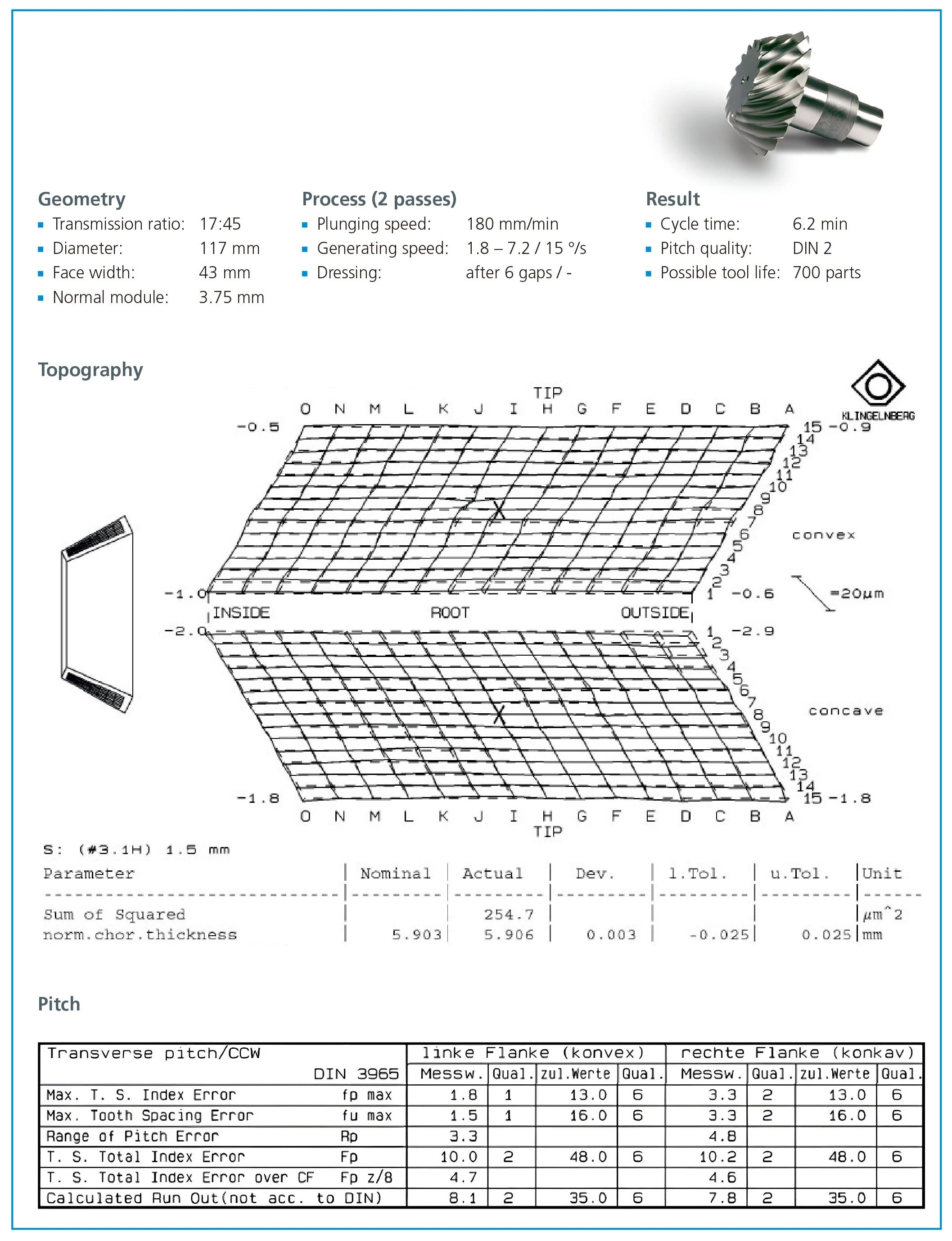

Figure 6 gives an example of a typical application area (see Figure 6). With suitable easy-to-process materials and optimized and adjusted process conditions, the gear can be ground from rough to finished product in 6.2 minutes. Theoretically, a single grinding wheel can achieve a processing life of 700 pieces.

Figure 6: Example of machining: passenger car pinion

The corresponding cycle time for deep grinding of the formed gear is 11.5 minutes.

08. SummaryIn summary

For low volume bevel gear production, deep bevel gear grinding provides an attractive alternative to conventional bevel gear precutting or 5-axis machining. In order to achieve the best treatment results, a closed-loop control system can usually be used. When starting out in bevel gear production or transitioning from traditional machines to digital production, investing in a gear grinding machine is an effective way to achieve high precision and flexibility with a relatively low investment.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.