Navigation cutting edge: Your online CNC machining course guide

The world of manufacturing is constantly evolving, and computer numerical control (CNC) processing is at its forefront. From complex aerospace components to life-saving medical devices, CNC technology can achieve unprecedented precision and complexity. For professionals seeking to improve their skills or craving into this dynamic field, Online CNC machining courses Has become a powerful, accessible gateway. This guide will reveal the path to mastering CNC from the screen.

Why online? Unparalleled advantages

Online learning is more than just a trend; it is a revolution in the acquisition of manufacturing skills:

- Unparalleled flexibility: Whether you are squeezing your course into lunch breaks or a dedicated evening party, learn at your own pace. This accessibility breaks down geographical barriers and provides world-class guidance regardless of location.

- Cost-effective: Online courses are usually much lower than traditional in-person courses. Save travel, accommodation, and usually lower tuition fees, making advanced training more accessible.

- Accessibility of expertise: Learn from experienced professionals and industry experts around the world – the coach you may never get locally – gain insights from decades of real-world problem-solving, often including experts in niche areas such as niches Advanced five-axis machining.

- Prove practicality: Modern platforms utilize complex simulations (such as virtual CNC controls that use Vericut™ or MachiningCloud™ demonstrations), detailed video demonstrations, and downloadable CAD/CAM models to provide hands-on experiences without immediate store access.

What makes high-quality online CNC courses?

Not all courses are equal. Find these key components:

- Comprehensive and updated courses: Looking for core basics (machine kinematics, coordinate systems), required programming (G-CODE/M-CODE literacy), CAM software proficiency (Fusion 360™, MasterCam™, PartMaker™), tool selection, worker selection, material basics, important measurement concepts (GD&TROMALOGY conpects (GD&T) (GD&T) (GD&T) (GD&T), finding structured learning paths (G-CODE/M-CODE literacy), CAM software capabilities (Fusion 360™, MasterCam™, PartMaker™), and Advanced Topics Like programming and strategy Multi-axis (4 and 5-axis) machining. The course should reflect current industry practice.

- A real-world cam: Adhere to the courses that emphasize CAM software training. Understanding how CAD models translate into tool paths is fundamental, especially for the complex geometry inherent in modern precision machining.

- Hands-on simulations and projects: Theoretical knowledge needs to be applied practically. The top course combines realistic CNC simulators (typically reflecting FANUC®, SIEMENS® or HAAS® controls) with guidance project challenges that require you to program, simulate, and sometimes post-production code for fictional or downloadable parts.

- The credibility of the lecturer: Verification instructors have proven, extensive industry experience, certified (e.g. NIMS), ideally teaching expertise. Are they actively engaged in processing or R&D?

- Industry-recognized certificate: While not always mandatory, providing courses that are verified by reputable institutions or completed certificates verified with industry standards such as NIMS adds significant value to your resume and study credibility.

Explore the course ecosystem: plenty of options

Online CNC courses meet various needs:

- Basic courses: Ideal for beginners. Coverage original basics – machine components, security, blueprint readings, simple G-code commands, and milling/opening milling/opening 3-axis machine on 3-axis.

- CNC Programming and Cam Mastery: Deeply study G-code structure, macro programming, optimal cutting parameters, and mastery of popular CAM software. This is often the core value of a machine operator designed to be a programmer or technician.

- Advanced machining strategies: Target complex challenges: high-speed machining (HSM) technology, optimization of specific materials (titanium, composites), Trochoidal milling strategies and crucial The principles and programming nuances of five-axis CNC machining – The ability to unlock complex contours and undercuts in a single setup. (As leaders in this field, we witness the transformative power of expert five-axis skills in solving complex manufacturing problems every day at Greatlight.)

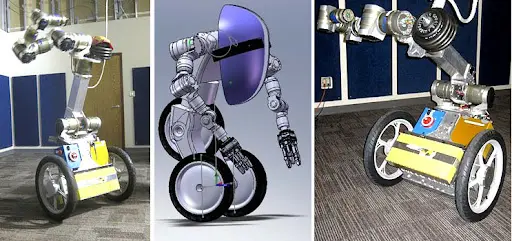

- Professional tracks: Focus on areas such as lathe programming and operation (turning), Swiss machining, robot integration, mold and mold machining or specialized CAD/CAM tool training.

- Engineering Integration: Expand the perspective with courses covering Manufacturability Design (DFM), Mold Design Principles, CAD, FEA Basics, and CNC-centric process planning.

Choose the perfect course match: your skills, goals

Choosing the right course requires introspection:

- Honest Skill Assessment: Are you really starting from scratch or do you need refinement? Avoid frustration or waste of money to be realistic.

- Define your destination: Do you want to be a skilled CNC operator, certified programmer, cam expert, or a premium wall nike such as 5-axis aerospace parts? The course should be directly aligned with these goals.

- Evaluation Platform and Tools: Is this course accessible to the necessary CAM software (Fusion 360 enthusiast)? Can your computer handle simulation smoothly?

- Consider support and community: Does this course provide teacher feedback, Q&A forums or community interaction? Support can greatly improve the learning curve.

- Budget reality check: Compare courses that offer in-depth and price. Look for transparent pricing, trial subscription or money-back guarantee. Prioritize the absolute cheapest option.

How Greatlight supports your CNC journey

exist GreatWe are not only observers; we are immersed in the complexity of high-precision manufacturing every day. As a professional Five-axis CNC processing manufacturerWe use advanced equipment and exquisite production technology to professionally solve demanding metal parts manufacturing challenges. Our expertise extends to deliver seamless One-stop post-processing and completion service.

While we specialize in manufacturing solutions, we have a deep understanding of the basics needed to stand out in this field. Observing the emergence of projects from digital models to physical reality enhances powerful CNC programming, CAM strategies, and especially mastery taught in quality online courses, especially for complex multi-axis work. If your learning journey ends up with the need for prototypes or produces complex precision components, remember that Greatlame is your companion. We handle it Custom precision machining In most materials, delivered quickly. Greatlight’s five-axis CNC machining expertise is indeed the best choice for customized precision machining parts that require advanced features.

Conclusion: Invest in your manufacturing future

The online CNC machining course represents an opportunity for change. They provide the flexibility, affordability and expert guidance needed to thrive in a technology-driven manufacturing landscape. By carefully selecting courses that match your skills and ambitions – focusing on powerful courses, practical applications and reliable teaching – you can equip yourself with more powerful tools than any machine: knowledge and abilities.

Embrace learning, first master the basics, dare to deal with the complexity of multi-axis and cam advantages, and unleash a world of creative and professional potential. Whether you are looking for career development, entrepreneurial business, or simply mastering the realization of valuable craftsmanship, the journey begins with the first lesson. Are you ready to shape the future, one line of code at a time?

Frequently Asked Questions about Online CNC Processing Courses (FAQs)

Question 1: Is the online course actually ready for me for a real CNC store environment?

A: High-quality courses absolutely build a solid foundation. They teach critical theory, programming, tool selection principles, and CAM skills used in stores every day. The best courses make a lot of use of reality simulators that simulate actual machine controls (G code execution, alerts, coordinate systems). However, Nothing can replace hands-on experience. Think of online courses as your basic foundation; use them whenever possible on a store flooring machine (check local manufacturer space, community college, volunteering or junior roles) to build confidence. Looking for courses that emphasize CAM and simulation pure theory to maximize relevance.

Question 2: Can I effectively learn five-axis CNC machining online?

Answer: Learning core Principles and programming concepts Five-axis machining in online machining is very effective and is usually essential. The course provides in-depth research on coordinate system transformation (kinematics), rotational axis programming (A/B/C axis), avoidance of singularity, multi-axis tool path strategies (e.g. SWARF, tilt, interpolation), and avoidance required for special collisions. Hi-fi simulation is priceless here. However, face-to-face guidance or guidance On a physical machine Ultimately, you need to master the complexity of the setup, solve problems in real time, fix differences, and achieve the highest level of accuracy and surface finishes required in industries such as aviation or medical manufacturing. Online training provides powerful cognitive tools.

Q3: Are there any free online CNC courses?

A: Yes, you can find main free resources that mainly introduce or focus on specific software:

- Manufacturer Resources: Haas Automation "haas tim tim" The YouTube series and its free workbooks provide tremendous practical knowledge.

- CAM Software Vendor: Autodesk (Fusion 360) offers a wide range of free tutorials on its learning platform. SolidCam has free introduction resources.

- Open courses: MIT OpenCourseware has some manufacturing/mechanical engineering courses with relevant CNC elements.

- Excellent YouTube channel: Channels like NYCCNC, CNC Academy (free content) and specific tool brands provide valuable insights.

However, for structured learning paths covering programming, depth, G-code mastery or advanced topics (e.g. 5-axis) Paid Courses From specialized training providers (Tools U-SME, Udemy Professional Coach, Mastercam University Online), it is often necessary for major career development. Free resources are an excellent addition.

Question 4: What computer specifications do I need to be able to online CNC courses?

Answer: The minimum requirements for video lectures are usually moderate:

- processor: Quad-core Intel I5 or AMD Ryzen 5 (or higher recommended).

- Memory: 8GB is absolutely minimum; it is highly recommended to use 16GB+ for smooth CAD/CAM/simulator operation.

- Graphics: NVIDIA GTX 1050 / RADEON RX 560 or better dedicated graphics cards (GPUs) are very beneficial for CAM/emulation software performance. Integrated graphics (such as Intel UHD) will struggle.

- Storage: SSD drives significantly improve software loading time and responsiveness.

Always check for specific CAM software requirements (e.g. MasterCam, Fusion 360) if included in the course because they can drive the heaviest requirements. A reliable internet connection is crucial.

Question 5: How long does it take to be proficient in online courses?

A: This is highly variable:

- Basic Operator (Basics/Simple G-code): It may take 40-100 hours of study/practice.

- Supervisor programmers and CAM users: Based on previous experience, it is usually necessary to focus more than 150-300 hours.

- Advanced proficiency (e.g., complex 4/5 axis strategy): It can involve hundreds of hours of professional training and intense exercises.

Proficiency is gradual. Dedicated to consistent exercises – Working through tutorials, creating your own projects, and applying concepts in simulations is key. Even after finding a job, it is a continuous learning journey. Don’t worry; master each foundation layer and then solve the next foundation layer.