3DOne of the most promising applications in the printing industry is the design and development of variable density buffer structures, an area that could provide new opportunities for additive manufacturing. (AM)This brings in billions in revenue.

Successful application development

HP、Carbon And EOS Continuing their research into variable density padding structures, these equipment manufacturers (OEM) Working with materials companies and manufacturers in areas such as hiking shoes, outdoor equipment manufacturers, bicycle seats and basketball manufacturers, we are growing3DPrint-centric end-use products. These three companies realized that to truly advance the development of additive manufacturing, they must integrate into the value chain and jointly develop revolutionary applications where their technologies can make a difference.

Cushioning performance

△PROCESS Bicycle seat.

3DA key area where printing can help is in providing cushioning for a variety of items including:

●Head equipment: helmet, mask, hearing protection, glasses, safety glasses, headphones

●Sports equipment handles, including handlebars and steering wheels

●Gloves

●Seats: bicycles, motorcycles, chairs, cars, truck drivers, delivery people, planes

●Headrest

●Backpack

●Skis, skates, slippers and shoes

●Grip surfaces for various sports, auxiliary and industrial equipment

●Prosthetics, orthodontic appliances, assistive equipment

●Computer mice and other peripherals

It can be seen that buffer structures permeate all aspects of life. It can be predicted that tampon applications could eventually become the largest and most profitable in the world.3DOne of the printing applications.

3DPrint shoes

Since the cost of additive shoes and insoles is currently very high, there is growing interest in these products.3DPrinted shoes are not promising. However, in the current business model, there are real opportunities for shoes, as they can be used to produce certain specialty shoes in low volume. Only when material costs are significantly reduced and true automation is established3DIt is possible to reduce costs when printing for production. More recently3DShoe printing faces the following problems, but some people will benefit from it3DRapid manufacturability and personalized customization of printing have been pioneered3DThe printed shoe market.

lattice structure

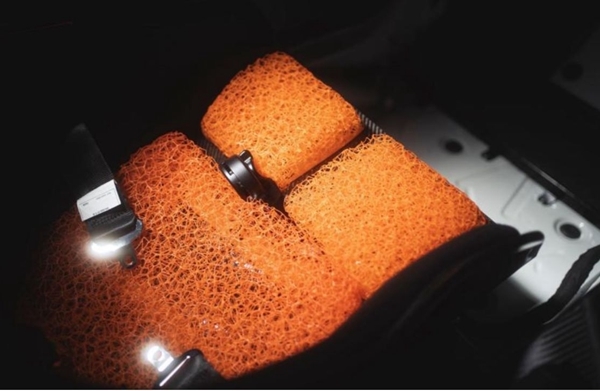

△BIOMIMETISM:3D Soft printed seats

Lattice structures are useful if you want to reduce the weight of a non-structural component somewhere and are the most important way to achieve damping while reducing material costs and printing time in photopolymerization technologies reducing and fusion on powder bed. Truss structures have many features and benefits. But currently, it is difficult to predict how network properties will change under repeated stress and forces, and it is possible that parts printed by powder bed fusion and vat polymerization will degrade after several charge cycles variable. These problems will improve over time, but there is a better solution.

Variable density insole

Variable density insoles appear in2014Years can change the softness and resilience of soles. Using material extrusion technology, users can print TPUsilicone or PPmaterial, then vary the thickness and pattern of the infill to match specific walking patterns, processing needs, etc. With this innovation, users can3D Print a single insole and each element can be designed to adapt to the user’s walking habits.

You can make it stiffer where your toes meet the sole, softer in another area, and have less lateral movement in other parts, all while making the back firmer and more comfortable for the wearer. Currently, there is still a huge vacancy in the market for this application and the outlook is very promising.

cushion

The mesh allows air to pass through and is very breathable, which is why a lot of bicycle seats and backpack cushions use a mesh structure. Helmets can pass 3D Printed structures that absorb rapid impacts and slow down heavy impacts; in the case of airplane seats or prosthetics, unique materials can be designed to provide the best long-term comfort; .

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.