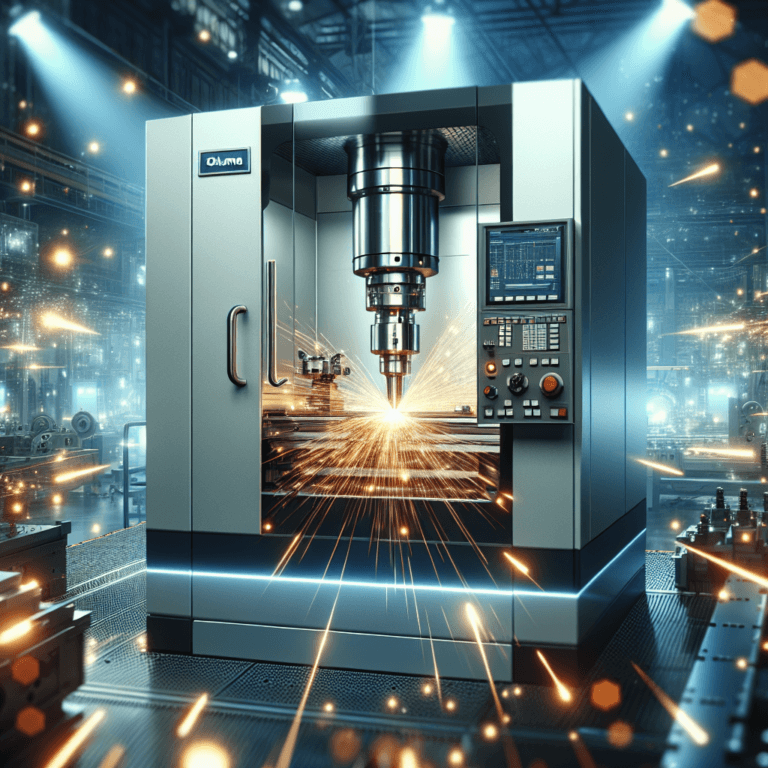

Unveiling the Okuma Turning Center: A Champion in Metal Processing

In the constantly evolving world of manufacturing, precision and efficiency are non-negotiable assets. One such asset is the Okuma Turning Center, an innovative solution that has changed the landscape of metal processing plants. This article delves into what makes the Okuma Turning Center a remarkable player in the industry and how it can enhance productivity for various metalworking applications.

The Evolution of Metal Processing Technologies

Metal processing has come a long way from the manual lathes and basic machining methods of the past. Today’s manufacturing environment demands unprecedented precision, speed, and reliability. Technological advancements have birthed advanced machinery that meets these requirements, and the Okuma Turning Center stands as a paragon of this evolution.

With the advent of CNC (Computer Numerical Control) technology, machining processes not only became faster but also allowed for complex shapes and designs to be created with perfect accuracy. Consequently, the need for advanced turning centers has skyrocketed. Okuma, a leading name in this sphere, has developed turning centers that cater to a vast array of machining needs with advanced features that make it an indispensable tool in metal processing.

Understanding the Okuma Turning Center

So, what exactly is the Okuma Turning Center? It is a highly advanced piece of machinery designed for precision metal cutting and shaping. Equipped with cutting-edge technology, the Okuma Turning Center provides manufacturers with robust and efficient solutions to meet their diverse machining needs.

Key Features

Robust Construction: The Okuma Turning Center is constructed with stability in mind. Its solid design minimizes vibrations, ensuring that the machining process does not compromise precision, resulting in high-quality output.

User-Friendly Interface: To streamline operations, the Okuma Turning Center features an intuitive software interface that allows operators to easily program, monitor, and adjust machining parameters.

High-Speed Machining: With increased spindle speeds and rapid movement capabilities, the Okuma Turning Center significantly reduces cycle time, enhancing productivity without sacrificing quality.

Versatility: One of the most notable aspects of the Okuma Turning Center is its versatility. It can handle a wide range of materials and is capable of performing various operations such as turning, milling, and drilling, making it a one-stop solution for many manufacturing plants.

- Smart Technology Integration: Okuma’s commitment to innovation is evident in its adaptive technology, allowing these machines to predict tool wear and provide data-driven insights to improve machining processes.

The Impact of the Okuma Turning Center on Manufacturing Efficiency

Enhanced Productivity

Productivity is a hallmark of any successful manufacturing operation. The Okuma Turning Center excels in this area by combining speed and efficiency. The high-speed spindle allows for rapid production rates, alleviating bottlenecks associated with conventional machining methods. In a world where time is money, the ability to complete jobs faster without compromising quality ensures that businesses remain competitive.

Precision Engineering

Precision is crucial in metal processing, and the Okuma Turning Center offers unparalleled accuracy. With features such as thermal compensation and backlash elimination, manufacturers can achieve tight tolerances with each part produced. For industries like aerospace and medical applications, where precision is critical, the reliability of the Okuma Turning Center can mean the difference between success and failure.

Reduced Downtime

Downtime can be one of the most significant costs for any manufacturing facility. The Okuma Turning Center incorporates advanced monitoring and diagnostics systems that minimize unplanned downtime. By predicting and diagnosing potential issues before they require expensive repairs, these machines contribute to more predictable production schedules.

Cost-Effectiveness

While the initial investment in a sophisticated piece of machinery like the Okuma Turning Center may seem daunting, the long-term cost benefits are significant. Here’s how:

Lower Operational Costs: By optimizing machining processes and reducing waste, the overall operational costs decrease dramatically.

Extended Tool Life: The intelligent monitoring systems in the Okuma Turning Center help to prolong tool life by providing insights on wear patterns, allowing for timely replacements or adjustments.

- Energy Efficiency: In today’s climate of rising energy costs, energy-efficient machinery provides a dual benefit of reduced overhead along with supporting sustainability initiatives.

Real-World Applications

The versatility of the Okuma Turning Center makes it relevant across various industries:

Aerospace Manufacturing: The aerospace industry requires extreme precision and quality. The ability to work with metal alloys with varying properties makes the Okuma Turning Center ideal for producing components such as turbine blades and housings.

Automotive Parts Production: The automotive sector relies heavily on CNC machining for components ranging from engine blocks to intricate electrical housings. The efficiency and precision of the Okuma Turning Center enable rapid prototyping and mass production.

- Medical Devices: With the need for high-precision parts in medical devices, the Okuma Turning Center ensures that manufacturers meet strict regulatory standards while maintaining quality and safety.

Future Trends in Metal Processing

As technology continues to advance, so will the capabilities of the Okuma Turning Center. Future trends in metal processing will likely include:

Automation and Robotics: Integrating robotics with CNC machining will further enhance productivity and efficiency, allowing for more complex tasks to be performed with minimal human intervention.

IoT and Data Analytics: Smart factories will leverage IoT technologies to gather data from machines like the Okuma Turning Center, transforming machine insights into actionable strategies for continuous improvement.

- Sustainable Manufacturing Practices: As industries move toward greener solutions, the adaptability of the Okuma Turning Center to incorporate energy-efficient practices will position it as a key player in the sustainable manufacturing landscape.

Conclusion

The Okuma Turning Center exemplifies the pinnacle of technology in metal processing. Its combination of precision, efficiency, and versatility makes it an invaluable tool for manufacturers aiming to thrive in a competitive marketplace. As industries evolve, the Okuma Turning Center is poised to lead the charge into a future shaped by innovation, sustainability, and automation.

Taking the plunge into advanced machinery like the Okuma Turning Center not only propels manufacturing capabilities but also supports the broader trend of agility and responsiveness in the modern manufacturing sector. Investing in such technology today could be the key to unlocking unparalleled growth and efficiency in the years to come.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.