Understanding Nylon in CNC Machining

Nylon, known chemically as polyamide, is a synthetic polymer that holds a significant place in the world of manufacturing, particularly when it comes to CNC (Computer Numerical Control) machining. With its excellent mechanical properties, versatility, and ease of machining, nylon has become a preferred material in various applications, from automotive components to industrial fixtures.

The Properties of Nylon

Nylon’s success in CNC machining lies in its unique properties. Here’s a closer look at the advantages it offers:

1. Strength and Durability

One of the standout features of nylon is its impressive strength-to-weight ratio. It boasts high tensile strength, which means it can withstand significant stress without failing. This makes it ideal for parts that are subjected to heavy loads or mechanical stress.

2. Lightweight

Despite its strength, nylon remains lightweight, providing manufacturers with an advantage when designing components where weight is a concern, such as in the aerospace or automotive industries.

3. Chemical Resistance

Nylon exhibits good resistance to many chemicals, making it suitable for applications that may involve exposure to oils, greases, and various solvents. This property extends the lifespan of machined parts, reducing the need for frequent replacements.

4. Low Friction Coefficient

Nylon has a naturally low friction coefficient, resulting in parts that operate smoothly and produce less noise. This quality is particularly beneficial for moving components, such as gears, bearings, and bushings.

5. High Temperature Resistance

While nylon can begin to lose strength at elevated temperatures, many grades are designed to withstand moderate heat. This makes it suitable for applications that may experience intermittent heating, such as in engine components.

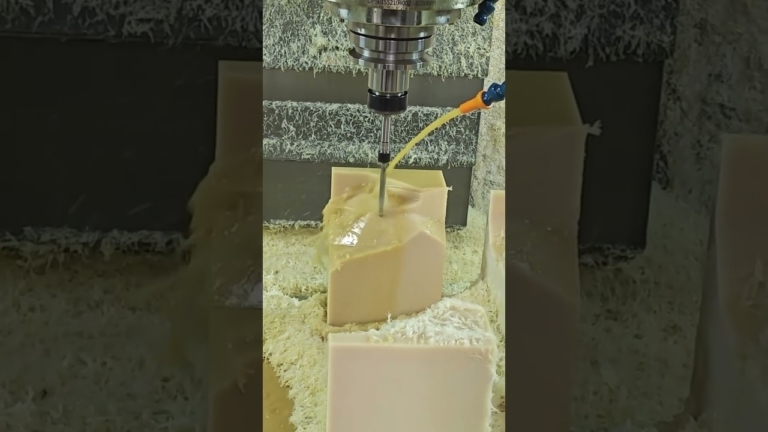

The CNC Machining Process for Nylon

When it comes to CNC machining nylon, the process often mirrors that of machining metals, but with some considerations specific to plastics.

1. Tool Selection

Selecting the appropriate cutting tools is crucial for successful nylon machining. High-speed steel (HSS) or carbide tooling is often preferred due to its ability to maintain sharp cutting edges. Additionally, it is essential to use sharp tooling, as dull tools can cause the nylon to melt rather than cut cleanly.

2. Cutting Speeds and Feeds

Optimizing cutting speeds and feeds is vital for achieving the best results when machining nylon. Generally, higher speeds are preferable due to nylon’s tendency to generate heat, which can lead to melting. However, it is necessary to find a balance to prevent excessive heat generation that could alter the physical characteristics of the material.

3. Cooling and Lubrication

Using a coolant or lubricant can greatly improve the machining process. It reduces friction, helps maintain tool temperature, and improves surface finish. Water-soluble coolants or vegetable-based oils are often effective choices for machining nylon.

4. Workholding

Proper workholding is crucial in CNC machining to prevent movement during the cutting process. Given the lightweight nature of nylon, clamping methods may need adjustments to ensure that parts don’t shift or become deformed.

5. Finishing Techniques

Post-machining, nylon parts may require additional finishing processes to enhance their performance and appearance. Techniques such as sanding, bead blasting, or applying coatings can improve the surface finish, reduce friction further, and enhance chemical resistance.

Applications of Nylon in CNC Machining

The versatility and properties of nylon lead to its use in various applications across multiple industries. Here are some notable uses of nylon machined parts:

1. Automotive Components

Nylon is commonly used in the automotive industry for parts such as bushings, clips, gears, and brackets. Its lightweight yet strong characteristics contribute to improved fuel efficiency and overall vehicle performance.

2. Aerospace Parts

In aerospace applications, nylon components can be found in non-structural parts where weight reduction is critical. Its ability to withstand impact and resistance to various chemicals make it suitable for use in aircraft applications.

3. Industrial Machinery

Manufacturers use nylon for producing various components in industrial machinery, including wear pads, rollers, and conveyor components. Its low friction properties help in reducing wear and tear in moving parts.

4. Electronics

Nylon’s insulating properties and resistance to electrical discharge make it suitable for electronic enclosures and insulating parts. It helps protect sensitive components from environmental factors and mechanical damage.

5. Consumer Products

From kitchenware to sporting goods, nylon is widely used in consumer products due to its versatility and ease of manufacture. Items like straps, containers, and handles benefit from nylon’s strength and lightweight properties.

Challenges in Nylon CNC Machining

Despite the benefits, there are challenges associated with CNC machining of nylon that manufacturers must address:

1. Thermal Expansion

Nylon can expand and contract with temperature changes more than other materials, which may affect precision during machining. It’s essential to account for this in the design and setup phases.

2. Moisture Absorption

Nylon is hygroscopic, meaning it can absorb moisture from the environment. This can lead to dimensional changes and impact the material’s mechanical properties. Drying nylon before machining can help mitigate these effects.

3. Post-Machining Warping

If not cooled correctly or machined properly, nylon parts can warp post-production. It’s crucial to allow parts to cool evenly and to consider potential stresses while machining.

Conclusion

Nylon CNC machining offers a plethora of advantages, making it a favored choice in various industries. Its unique combination of strength, lightweight nature, and ease of fabrication allows for high-quality components that meet the demands of both precise engineering and everyday applications. As manufacturing technology continues to advance, the future of nylon in CNC machining appears promising, providing innovation and enhancement across countless sectors.

With a greater emphasis on eco-friendly materials and sustainable practices, nylon—and its various forms—will likely remain significant in modern manufacturing. As manufacturers continue to refine their techniques and embrace new technologies, nylon CNC machining will undoubtedly evolve, offering even more possibilities for innovation and efficiency in the world of production.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.