According to Mohou.com,2022Year8moon9Japanese and New Zealand artistNicole Honédevelop a unique experience4DPrint art infused with natural beauty and expanding the scope of what’s possible with multi-material printing.

Horn (Sharpen) is from Victoria University of Wellington, New Zealand3DPrint research assistant and scientific green beauty brandAntipodesgraphic designer, with his mentor the famous industrial designer Stevens (Ross Stevens) work together. In Horn’s latest collaboration with Stevens, they designed and printed objects that interact with natural elements such as water, air and ice, displaying them in an attractive way. This piece is a visually stunning print that interacts elegantly with other elements without complicated manipulation.

This project comes fromDO(Multi-Attribute Additive Manufacturing Design Experiment) is a research direction of the School of Design and Innovation at the University of Victoria. It mainly focuses on multi-material printing, also known as liquid printing research. he usesStratasysTest software developed by the company andJ7AndJ8series3D PolyjetPrinter materials.J7AndJ8Part of this pioneering brand’s product portfolio, it is designed for high-volume, high-speed multi-material printing for a variety of design and engineering applications.

For more than ten years,MADE searchAndStratasys Always working to grow by developing new applications and printing materials 3D Printing technology. This collaboration recently made it possible DO Be part of an exclusive group of researchers with access toStratasysbusiness J7 And J8 printer. then in2021 Year,Stratasys spearPolyjet Research software package for printing flexible parts, hydraulic systems or fluid models with liquid support materials.

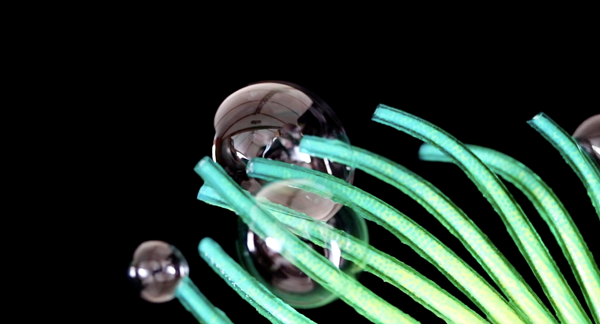

△NicoleHoneAndRoss StevensLiquid printing project, here the four liquid elements release bubbles. Photo byNicole Honéprovide.

With these powerful printing systems in hand, Stevens and Horn began developing designs for their2022Annual projects design new objects. First, the pair released three videos of printed structures. The first paragraph is “four element liquid“showing algae4DA scene where the work interacts with the four elements: air, smoke, ice and water. At the same time, “Liquid Leaf”/LeavesLiquids》 shows that when a liquid element is inserted through a small tube,4DHow printed sheets move. Finally,Polyphytesis a beautiful design that hides various elements with a harmonious elegance specific to this project.

DoAccording to the Liquid Printing Project website:“Our main intention is to show how these simulated objects can create powerful visual effects without requiring lengthy digital manipulations and are, in fact, their simulations.‘chance‘Exceeding digital creative potential in every detail.“

The research team will not discuss how the structures were created as the process is still in the testing phase. However, they explain that new software, printers and liquid media can enable smaller, more reliable and more complex internal channels to be printed directly on objects.PolyjetThe technology’s liquid printing capabilities enable the creation of these leak-proof, liquid-filled cavities inside objects. Previously, these cavities were filled with support material and difficult to clean. The final structural design allowed “Multidimensional interaction with actors or audiences“。

Sharpenexist2022Year7Lunar”Design boom» The magazine published the results of its project, focusing onPolyphytesThe development process behind this. In the published article, the designer explains that the basis of his work is based on3DLinks between imprinted channels and the vascular system of native plants. Additionally, the film from his research project (shown below) explores the flow of different substances throughPolyphytesVarious physical effects produced during use: water, air, smoke, candy sugar, foaming mixture and soap.

Sharpenin herDesign boomThe article explains:“Polyphytesin design softwareHoudiniModeled procedurally, there are a series of internal channels, some with diameters as small as1mm then inStratasys J850Printed in full color rigid photopolymer resin with varying levels of opacity. The closed gap was initially composed ofPolyjetThe cleaning fluid fills and then empties in post-production, making the channel instantly fluid.“

The designers say that while research focuses on cinematic applications of the new material, its potential could easily extend to medical and other creative uses. Victoria and Ross University–Stevens has a history of working in film studies, Stevens even led a project at the School of Design where he explored3DAnd4DPrint and create computer-generated images (Synthetic image) is a term for the use of computer graphics to create images in a wide range of niche fields, including film and computer animation.

△Nicole–horn and rose–Stevens’ liquid printing project, here is a succulent plant releasing water. Photo byNicole Honéprovide。

Although2015proposed by StevensFlexibleproject timeSynthetic imageYet another novelty (see3DPrinted objects interact with humans in real life and display the organism’s characteristics), but3DPrinting enthusiasts are already paying attention to new developments. One of them is object reality (OR), a new term he developed to describe digital objects taken from the virtual world and brought to life in the physical world, expanding the world of digital creation.

Stevens, Horn and other School of Design graduate students have been heavily involved in projects with New Zealand-based special effects and props company Weta Workshop. Much of the work carried out at Victoria University has provided an excellent foundation for projects at award-winning companies. Students have even found employment helping create special effects for many beloved shows and movies.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.