The invisible engineering miracle: yours "Naughty pin" The power of pen holder and precision metal 3D printing

We’ve all seen them. The ubiquitous little metal wire puzzle is located next to the keyboard or on a global table. Playing is called "Naughty pins," "Endless pins," or "Wire puzzle," These seemingly simple table toys (usually doubled by pen holders) provide endless irritating entertainment. Their hypnotic movements seem effortlessly – a satisfying continuous flip cycle. But have you ever stopped thinking about the manufacturing precision required to create this seemingly trivial object function Perfect? This is advanced art and science Metal 3D printingcourtesy of experts like Greatlight, turns a simple concept into a functionally perfect, durable and beautiful project.

Beyond Trouble: Decode the Naughty Pin

The naughty pin holder relies on a key geometric principle at the core: Accurate parallel alignment of multiple curve segments. Each segment must be perfectly formed and welded to form and weld at precise angles, creating smooth channels to guide the central roll ball or bearing without capturing, binding or creating dead spots. The tolerances involved are very tight. Even slight deviations – imperfect curve radius, slightly misaligned at the weld, microscopic surface roughness – can also turn smooth, endless motion into frustrating sticky glitches.

Why traditional manufacturing volumes reach the limit (even for small parts)

You might think "This is just the curved wire! Why not machine or stamp?" For large, low-quality versions, these methods do exist and usually lead to:

- Inconsistent bending: Using traditional bending techniques to achieve the same curve on multiple thin lines is challenging, resulting in changes in track geometry. This inconsistency can ruin smooth scrolling.

- Welding distortion: Connecting thin lines to spot welding methods such as introduction of local thermal distortion or material warping, thus getting rid of critical alignment between segments.

- Surface defects: Rough edges, burrs or welds can capture rolling elements, resulting in obstacles and jerky movements. Manual sanding may be inconsistent or damage the thin wire.

- Complexity limitations: For small batches of conventional tools, more complex or customized designs (different sizes, integrated foundations, unique track shapes) become very expensive or impossible.

- Material constraints: In harder alloys, both the necessary strength and smooth surface finish can be achieved in hard alloys like stainless steel, which is difficult to bend separately.

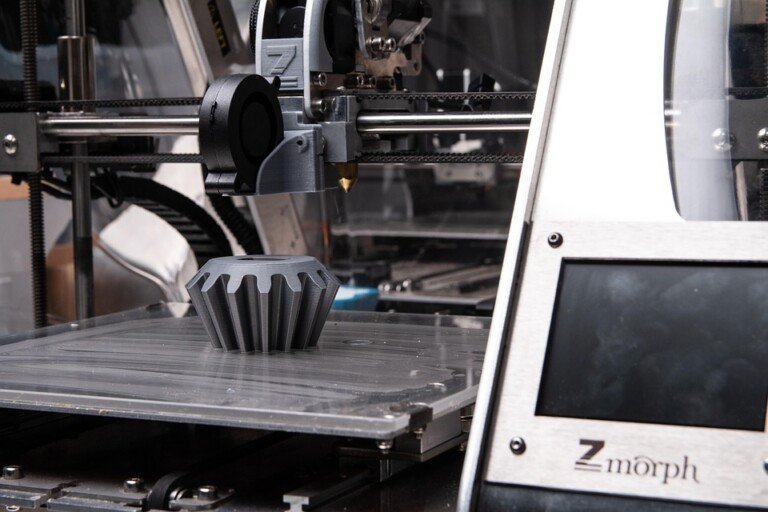

3D printing of input metal: Precision engineering

This is Greatlight’s expertise in professional aspects Metal 3D printing shine. Using processes like selective laser melting (SLM) or similar advanced powder bed fusion (PBF) technology, we have made the entire naughty pin pen holder frame – foundation, support column and crucial Single merge components. This eliminates the changes, misalignment and weakness introduced by multiple manufacturing steps (bending, welding). This is the impact:

- Unparalleled geometric accuracy: Each curve, each angle, and each internal track surface is constructed directly from the digital CAD model. This ensures geometric perfection, allowing smooth, barrier-free movement where the rolling elements interact with the track.

- Seamless integration: The foundation, support and track become a unified whole. No welds, no assembly errors – inherently robust structure.

- Microscopic surface: Metal 3D printed parts can achieve incredible smoothness "first aid" The surface of the key areas greatly reduces the friction of the machine. This minimizes the initial "break in" Time and provide a consistent feeling.

- Material versatility and power: Greglight uses high-performance alloys Stainless steel (316 liters, 17-4ph), titanium, aluminumand nickel alloy. This allows for durable, corrosion-resistant parts (perfect for desktops) and is able to be used continuously without bending or losing shape. Fingers can be flipped endlessly without worrying about damage.

- Freely customized design: Want a unique base shape? Integrated company logo? Specific colors? Custom track layout? Metal 3D printing makes it possible without expensive customization tools. Small batches or prototypes are economically feasible.

- Consistency Guarantee: Each naughty pin holder printed in batches is the same size and is functionally equivalent.

Great Advantage: Perfect Post-processing

Metal 3D printing provides incredible initial geometry, while Greglight’s Professional service completion Raise naughty pin holders to advanced levels:

- Precision machining: The critical contact surface facing the rolling element can receive a microbuffer to make it smoother, mirror-like finish that reduces friction to nearly zero.

- Surface finish: Options such as vibrating tumbling, electropolishing, or media blasting eliminate any tiny surface irregularities and enhance aesthetics, creating a luxurious feel.

- Plating/coating: Apply decorative or functional coatings such as nickel plates, chrome plating, PVD coatings or color anodization to enhance visual appeal and additional durability.

this One-stop manufacturing solution – From optimized digital design and precise printing to expert finishes – Ensure that the final product not only works perfect from the first flip, but also looks stylish and professional on any table.

in conclusion

The modest naughty dowel holder is an interesting case study in the hidden elaboration of everyday items. What seems simple is the basis for requiring precise engineering. Greatlight Metal 3D printing provides a transformative solution that overcomes the limitations of traditional manufacturing for such complex, tolerant metal components. By building the entire structure with laser-like precision on powerful, high-quality materials and application expert finishes, Greatlight ensures unparalleled functional performance, durability and aesthetic quality. Whether it’s buying customized corporate gifts, premium branded merchandise, or only meeting your irritable needs with the highest quality, accurate 3D printing naughty pen holders prove the excellence of innovation and manufacturing.

FAQ: Naughty Pin Brackets and Greatlight Metal 3D Printing

Q1: What exactly is it "Naughty pin" Holding a pen?

A: This is a popular bench toy and pen holder, composed of multiple curved metal wires, forming the metal ball or bearing of the cradle. The ball can be flipped endlessly along the track with a satisfying rolling motion.

Q2: Why is it so easy to choose metal 3D printing? Is it not expensive?

A: Although simpler versions exist, there are considerable differences in functionality quality and durability. Metal 3D printing allows unparalleled accuracy in the geometry and alignment of the track, guaranteeing smooth, silent and perfect scrolling. It can make complicated custom design impossible by bending wires. For small batches, custom designs or requiring high quality, durability and performance, 3D printing is often the most effective solution, especially with Greatlight’s optimization process and completed solutions.

Q3: Which material is best for printing naughty pins?

Answer: Greatlight recommends:

- Stainless Steel 316L: Excellent corrosion resistance, excellent all-round durability, good surface effect.

- Stainless steel 17-4ph: The strength and hardness are higher than 316L, and excellent corrosion resistance. Ideal for demanding use.

- Titanium (Ti6al4v): Very high strength to weight ratio, excellent biocompatibility and corrosion resistance for advanced applications.

- Aluminum alloy (e.g., Alsi10mg): Lightweight, good thermal conductivity, more economical for a few applications. Durability may be lower than steel.

Q4: Can you make the smoothness of the rolling track?

A: Due to the high resolution of our printing process and our post-processing capabilities (including precise machining and polishing of critical surfaces), we can achieve extremely low surface roughness (RA values) directly in the contact area. This minimizes friction and ensures that the ball has little noise or resistance to move.

Q5: Can I customize it?

Answer: Absolutely! This is the key strength of 3D printing. Greglight can design with you:

- Completely unique base shape (company logo, abstract design).

- Customize track layout or size.

- Different heights or footprints.

- Integration of mounting holes or other functions.

- Choose metal material and final finish/coating. Personalization is easy to achieve.

Question 6: Does Greglight also provide rolling balls?

A: Yes, we can purchase and provide precise rolling elements (balls, bearings) made of hardened materials such as chrome-plated steel, stainless steel or silicon nitride ceramics to complement the pen holder.

Question 7: What is a typical application besides desktop toys?

A: Apart from a single irritable toy, they perform well:

- Customize company gifts and high-end promotional projects.

- Senior Staff Award or Recognition Program.

- "Fundamentally reimagined" Functional artwork.

- Sensory aids.

Question 8: What is the minimum order quantity (MOQ) for custom naughty pin holders?

A: Gremplying specializes in prototypes and production. When we produce large industrial parts, we can also accommodate smaller batches for high-value items such as custom naughty pins. The quantity varies depending on the complexity of the design and the material, so please reach out for a specific quote. Even for small exploratory operations, we are competitive.

Ready to lift the table with the perfection of precise design? Or create unique functional brand works? Contact Greatlight today to discuss your custom metal 3D printing pen holder’s ideas and experience our commitment to quality, innovation and service.