Complex engineering applications have created an increasing demand for engineered structures or materials with multiple favorable properties. Metamaterials with multifunctionality through their structural configuration have unique advantages over traditional materials. Metamaterials are artificial materials consisting of a specific arrangement of carefully designed structural elements that can achieve unique electromagnetic, optical, acoustic, mechanical, thermal and other properties, such as invisibility, vibration reduction, sound absorption, energy absorption, etc. Vibration damping and energy absorption are two important properties that are highly compatible in engineering applications, but to date, few studies have focused on realizing multifunctional metamaterials with these two properties. Researchers such as Jiang Weifeng from the School of Mechanical Engineering at Sichuan University in China have proposed a new three-dimensional lattice structure with vibration reduction and energy absorption capabilities. Through numerical simulations and experiments, it is proven that the proposed metastructure can attenuate low-frequency elastic waves through local resonance and absorb impact energy through buckling deformation. Additionally, a functional classification strategy is proposed to further improve vibration damping and energy absorption. performance of networked metamaterials.

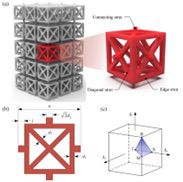

First, the researchers designed and fabricated the network and obtained the mechanical properties of the base material through experiments. First select a face-centered cube with good compressive strength (FCC) frame to replace the uniform mass and form a resonator with the pillar hanging in the center of the face to achieve local resonance, as shown in the figure1(a)watch. The main parameters include the width of the edge pillard_1width of the connecting pillard_2diagonal support widthd_3length of connecting pillarIand unit cell lengthAas shown in the figure1b)illustrated; then use thermoplastic polyurethane (TPU) powder by selective laser sintering (SLS) craftsmanship (EOSP396Germany) on samples3DPrint finally based onISO 527Standard universal electronic testing machines are used to obtain the mechanical properties of materials.

picture1 Three-dimensional network metamaterial structure

Then, the researchers carried out dispersion relation calculations, numerical simulations and experimental tests of wave transmission. Use finite element modeling first (FEM)softwareCOMSOL Multiphysics 5.6The dispersion relationship and transmission spectrum were calculated, and the dispersion relationship of the proposed structure was plotted, as shown in Figure1c)shown, then through the electromagnetic vibrator (WL010Beijing Yiyang Yingzhen Testing Technology Co., Ltd.), dynamic signal acquisition and analysis system (Germanym+pinternational company), power amplifier (WL010ABeijing Yiyang Yingzhen Testing Technology Co., Ltd.) andm+p analyzerSoftware (Germanym+pInternational Company) to obtain the transmission rate, where the sample used in the experiment is shown in the figure2(a)As shown in the figure, the test system2(b)is shown finally, by understanding the bandgap formation mechanism and calculating the dynamic effective mass density of the proposed lattice metamaterial, it is concluded that the proposed lattice structure leads to the formation of low frequency bandgaps through local resonance , which achieve vibration damping performance. At the same time, the researchers also pointed out that the local resonance frequency can be manipulated by selecting appropriate geometric parameters.

picture2 Schematic diagram of the experimental setup for testing the transmission of a finite size network structure

The researchers then conducted quasi-static compression experiments and numerical simulations. First use a universal electronic testing machine (Instron 5967UNITED STATES)3DThe compression response of the printed sample, as shown in the figure3(a)watch ; then use finite element softwareAbaqus/Explicit 2020The quasi-static compression process is simulated, as shown in Figure3b)finally shown the simulated and experimental compressive forces are obtained;–Displacement curve, as shown in the figure4As shown, it can be seen that the compressive force obtained from numerical simulations and experiments–The displacement curves show good quantitative consistency, and the corresponding deformation patterns under different deformations are obtained, as shown in Figure5As shown, it can be seen that the deformation is mainly divided into4steps: −16% ≤\varepsilon<0Elastic step: composed of parallels toxyIt is caused by the elastic deformation by bending of the diagonal pillars of the plane. At this stage, the edge pillars show practically no deformation and the stress is concentrated at the connection nodes of the diagonal pillars and the overhanging pillars;20% ≤\varepsilon −16%Elastic stage: when the compression displacement exceeds the length of the connecting spacers,FCCThe frames come into contact and the edge struts are subjected to axial loads. With further compression, the struts deform elastically and the reaction force reaches an initial peak;54% ≤\varepsilon −20%Plateau stage: After the reaction force reaches the initial peak, it falls onto the platform due to the release of strain energy. At this time, the pillar gradually collapses and most of the energy is absorbed; \varepsilon−54%Densification stage: With larger compression displacements, almost all struts collapse and come into contact with each other, then the force increases rapidly until the sample is completely compacted.

picture3 Quasi-static compression test

picture4 The compressive force of the lattice structure obtained from experimental measurements and finite element simulations–Displacement curves and energy absorption efficiency

picture5 Deformation behavior of lattice structures from experiments and finite element simulations

Finally, the researchers proposed that functionally classified designs have good potential to optimize the versatility of vibration damping and energy absorption. For example, changing the width of the edge struts and connecting struts will have a significant impact on the position of the upper and lower edges of the bandgap. As the width of the edge spacers increases, the bandgap gradually expands and shifts toward one. higher frequency range, while as the size of the connecting struts increases they become narrower, as another example, hierarchical truss structures allow changes in stiffness and mass distribution to adjust the response in compression of the structure, for example by manipulating the location of the initial deformation; and the sequence of deformation layers, contributing to stiffness design and deformation design. It follows that structure-based versatility is not limited by constituent materials and is highly customizable. By rationally considering more geometric parameters and more diverse ranking methods and hierarchical structures, a high degree of design freedom can be provided to meet the needs of multifunctional performance in different application scenarios.

The lightweight network metamaterial proposed in this study has both vibration damping and energy absorption properties. At the same time, the realization of multifunctionality comes from the structural design of the microgrid. Therefore, the network structure can be adjusted by designing geometric parameters. stiffness and relative density are used to control its operating frequency range and compression performance. This research provides a promising design avenue for the development of multifunctional metamaterials for specific engineering applications.

References:

Jiang W, Yin G, Xie L et al. “Multifunctional 3D lattice metamaterials for vibration attenuation and energy absorption.” International Journal of Mechanical Sciences (2022).

Source: Chinese 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.