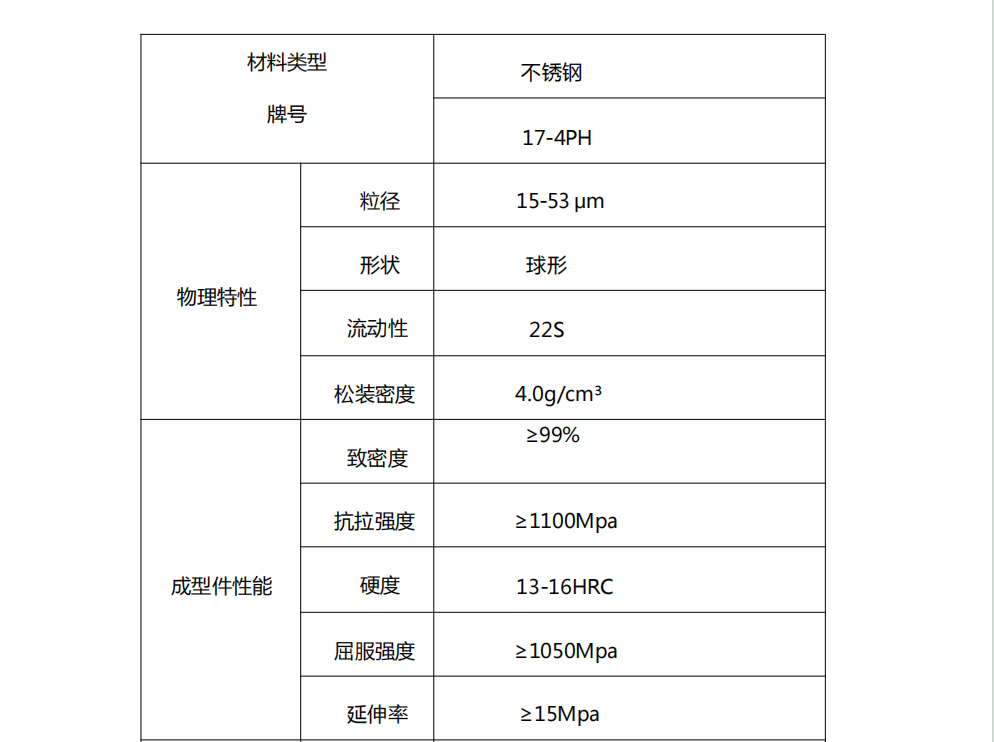

17-4 stainless steel is a versatile steel designed for industrial applications, also known as 630 precipitation hardened stainless steel strip. Alloy 17-4PH is a martensitic stainless steel whose main component is copper (the main components of 316L alloy are chromium and nickel). .

17-4 stainless steelfeatures:

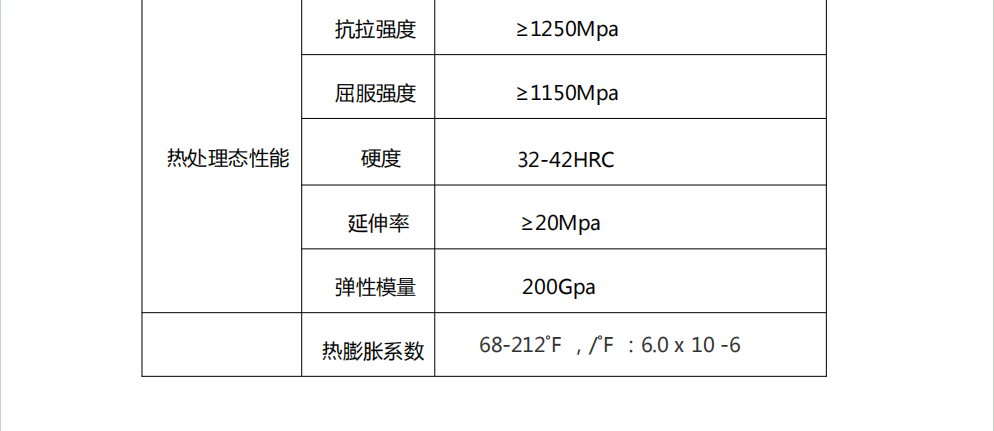

After heat treatmentthe mechanical properties of strip products are more comprehensive, and can achieve the highest compressive strength of 1100-1300 MPa (316L is only about half, 500-600 MPa).

17-4 PH stainless steel strip cannot be used at temperatures above 300°C or very low temperatures,It has good corrosion resistance to the atmosphere and diluted acids or salts. Its corrosion resistance is the same as that.304 is the same as 430,Not as good as316L.

evenCompared with 316L, 17-4PH has better mechanical properties, is more suitable for the manufacture of mechanical parts, and has better strength and hardness.

316L is cheaper, has better toughness and corrosion resistance.

Main applications of 17-4PH stainless steel:

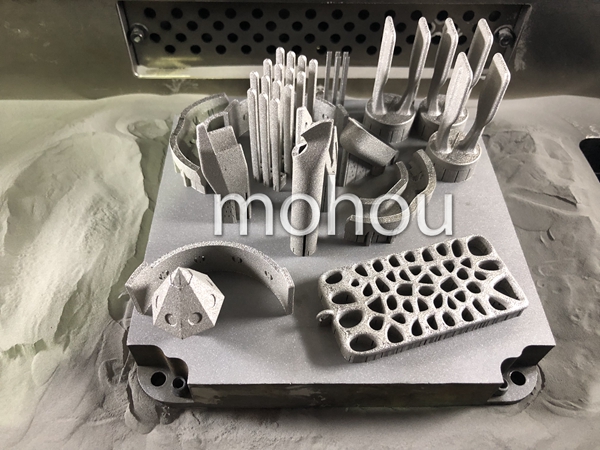

17-4PH is more suitable for industrial parts, such as

High wear tools

Lightweight support

key socket

gear

Flanges and valves

stationery equipment

airplane parts

Oilfield Equipment

Chemical equipment

Pump accessories and shafts

Other precision parts

Main application areas of 316L stainless steel

Chemical and petrochemical industry

food processing

pharmaceutical equipment

medical equipment

drinking water

wastewater treatment

Marine applications

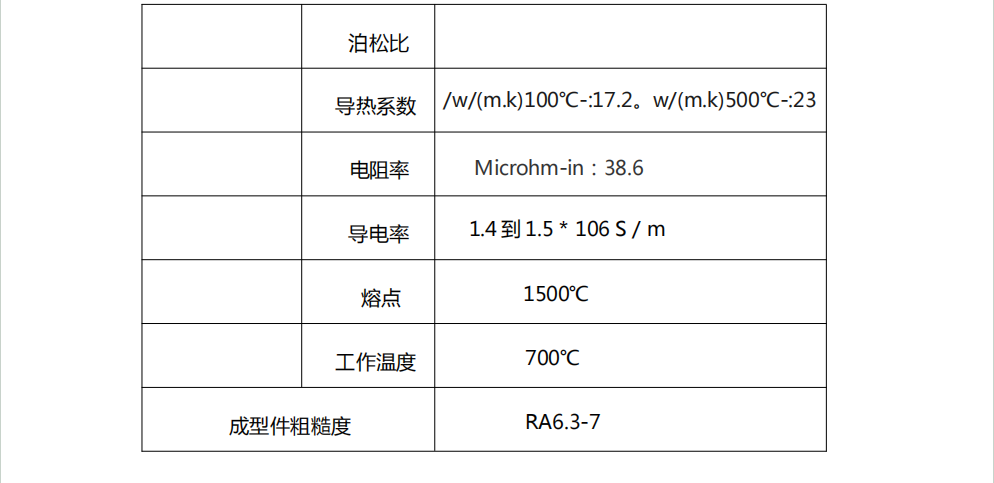

17-4 stainless steelPhysical properties table:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.