The evolution of manufacturing: Millennium CNC Insights unlocks potential

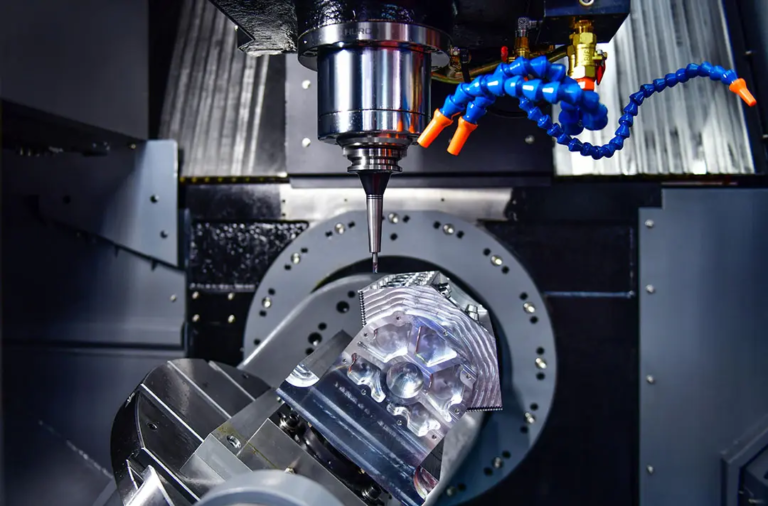

In today’s hypercompetitive industrial landscape, accuracy, complexity, and speed are unnegotiable. For businesses that require top-notch custom metal parts, the shift to advanced manufacturing solutions is not only beneficial, it is essential. The forefront of this revolution is five-axis CNC machining, a technology that changes the way complex components are conceptualized and built. Greglight is a leader in the field, reflecting this progress by leveraging refined five-axis capabilities to address manufacturing challenges that were once considered insurmountable.

Why is five-axis CNC a paradigm transfer

Unlike traditional three-axis machines that are limited to linear motion, five-axis CNC machining introduces axes of rotation (A and B), allowing the cutting tool to approach the workpiece from almost any angle in a single setup. This eliminates multiple repositioning and manual interventions, greatly reducing errors and lead times. Industry such as aerospace, medical implants, automotive and energy rely on parts with complex contours, deep cavity and strict geometric tolerances (parts where accuracy is crucial).

Consider aerospace turbine blades or spinal implants: their organic geometry requires uninterrupted toolpaths and a perfect finish. Five-axis machining not only achieves this, but also optimizes tool life and material removal rates, combining efficiency with uncompromising quality. It’s no longer milling metal; it’s about achieving engineering perfection.

Greglime: Engineering excellence in five-axis machining

At Greatlight, we are not only operating machines; we plan and make symphony. Our facilities feature state-of-the-art five-axis CNC centers, equipped with high-speed spindles, real-time monitoring systems and adaptive control technology. This allows us to deal with the following diverse materials:

- Aviation alloy (titanium, inconel)

- High-strength steel

- Aluminum and copper

- Engineering Plastics (PEEK, ULTEM)

- Non-produced metal

Beyond tailoring, Greglight Soluves solves it Create pain points:

- Complex geometric shapes: Undercut, composite angle and free form surfaces are performed with micron-scale accuracy.

- Production prototype: Transition from small batch R&D batches to full-scale production.

- Complex thin-walled challenge: Fixed sensitive or easily vibrated parts benefit from reduced setup and dynamic stability.

Your end-to-end manufacturing partner

We recognize that processing is usually a link in a larger chain. That’s why Greatlight provides integrated Post-processing and completion of servicesmake sure your parts are ready for use immediately:

- Surface treatment (anodized, electroplating, passivation)

- Heat treatment (annealing, hardening)

- Precision polishing and grinding

- Non-destructive test (X-ray, dye penetrant)

This holistic approach eliminates supply chain friction, saves time, reduces logistical overhead and ensures cohesion control.

Why Greatlight is good at your precise partner

- Technical expertise: Our engineers combine decades of experience with ongoing training on the latest CAM software and tool strategies to address projects that others consider to be unfeasible.

- Fast Market: With optimized workflow and multi-axis efficiency, we provide fast turnaround without sacrificing accuracy.

- Cost Efficiency: Reduced settings, adaptive tool paths and minimal waste conversion to better value. Our market balances advanced features with competitive prices.

- Reliability and Accountability: From DFM feedback to final inspection reports, we adhere to a strict ISO compatibility process. Each section is verified to your exact specifications.

With Greatlight, you are not outsourcing parts; you are gaining collaborators dedicated to success. Whether it’s a single prototype or a 10,000 unit order, our task is to turn your design into a flawless reality – more efficient, smarter, and more efficient than traditional methods.

in conclusion

The era of broken, inaccurate manufacturing is disappearing. Five-axis CNC machining, especially in Greatlight mastery, unlocks unprecedented freedom in execution design and reliability. By combining state-of-the-art technology with comprehensive services and deep technical acumen, we enable the industry to surpass limitations. For custom metal parts that require exceptional speed, complexity and finish, working with Greatlight transforms ambitions into tangible, precise design success. Share with us your toughest machining challenges and experience what truly advanced manufacturing can achieve.

FAQ (FAQ)

Q1: What makes my project make five-axis CNC better than 3-axis or 4-axis?

Five-axis machining allows simultaneous movement on five axes, thus completing complex geometry (such as features of curved surfaces or angles) in a single setup. This reduces cumulative tolerance error, improves surface effect, reduces lead times, and minimizes material handling methods compared to the need for multiple fixation stages.

Q2: Can Greatlight handle high temperature alloys such as Inconel or Titanium?

Absolutely. Our five-axis centers use specialized tools, high-pressure coolant systems and thermal stability protocols to effectively machine reactive or hard metals such as titanium, inconel and tool steel. We dynamically adjust feed/speed to manage heat and tool wear for dimensional stability.

Question 3: Do you provide design help (DFM) for complex components?

Yes. Our engineering team provides designs that offer design manufacturability (DFM) at no additional cost. We optimize the design to enhance processability, reduce costs and prevent potential production traps without compromising functionality.

Question 4: What tolerances can be consistently implemented?

Although tolerances vary by part size and material, we usually maintain ±0.001" (±0.025mm) for standard processing, down to ±0.0002" (±0.005mm) Critical dimensions are performed through auxiliary processes. We use CMM, optical comparator and surface manager instrument to verify tolerances.

Q5: How fast is the turnover time of custom parts?

Prototypes can be less than 3-5 working dayswhile production batches are optimized using parallel processing strategies. We prioritize transparency – core periods and pricing are detailed, with no hidden fees.

Question 6: Does the processing quotation include completion services?

Finishes (e.g., anodizing, plating, polishing) are referenced separately according to your specifications. However, as a one-stop partner, we manage the entire process (from raw materials to shipping parts) to ensure consistency.

Question 7: How to ensure quality control throughout production?

Quality is embedded in each step: preprocessing material certification, process inspection (verified using probe tool), and final inspection of metrological inspections driven by CMM and AI. Complete documentation (PPAP, ISIR) is available upon request.