Microalgae are a diverse group of photosynthetic microorganisms that are estimated to produce approximately50% oxygen. As renewable raw materials, they already have many applications, for example in food production or energy production. But another exciting area of application is opening up for microalgae, which could play a key role in medicine thanks to 3D printing.

from the Institute for Molecular Systems and Advanced Materials Engineering at the University of HeidelbergAn international research team led by Professor Eva Blasco has developed the first microalgae-based ink for 3D printing of complex, biocompatible microstructures with lasers. She notes that to date, polymers of petrochemical origin have mainly been used, in particular for the two-photon polymerization necessary for the creation of microstructures. These polymers contribute to the consumption of fossil fuels, greenhouse gas emissions and often the use of toxic ingredients. On the other hand, new inks based on microalgae represent an environmentally friendly alternative.

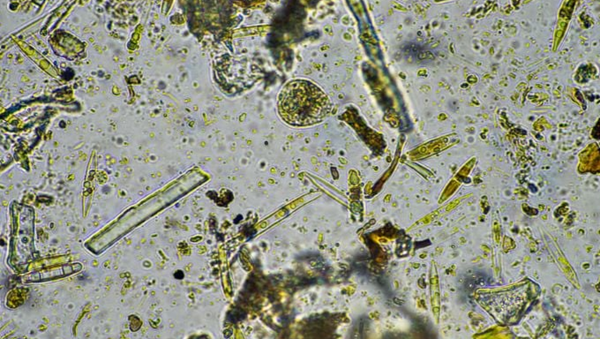

Diatoms and aquatic microorganisms

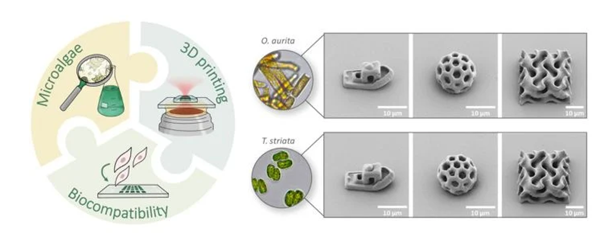

Two types of algae particularly rich in fats in the form of triglycerides were used: diatomsOdontella aurita and green algae Tetraselmis striata. To produce microalgae ink, triglycerides are extracted from algae and functionalized with acrylates for rapid curing. When exposed to light, the photoactive green dye triggers a chemical reaction that hardens the microalgae ink. “We therefore avoid using potentially toxic additives, such as photoinitiators used in conventional inks,” explains Clara Vazquez-Martel, doctoral student in the Eva Blasco research group at IMSEAM.

To test the biocompatibility of the microalgae ink, the researchers conducted experiments on the cell structure. That’s why they didThe survival rate of cells cultured on the 3D microscaffold for 24 hours reached 100%, which was impressive. Professor Blasco emphasizes: “Our results open up new possibilities not only for more sustainable optical 3D printing, but also for applications in life sciences, from 3D cell cultures to biocompatible implants. »

Microalgae ink enables production of complex materials with superior quality and precision3D microstructures are possible (Photo credit: Clara Vazquez-Martel).

In the future, microalgae inks could be used in medicine to produce precise micro- and nanostructures, or asThe basis of implants and scaffolds for 3D cell culture. Thanks to its high resolution, it also offers potential for applications in optics, photonics, microfluidics and biomedicine. Due to its biocompatibility, it is particularly suitable for printing products that come into contact with living tissues.

At the same time, the new material protects the environment because algae grows quickly and produces carbon dioxide when grown.“Despite their many advantages, microalgae are hardly considered as a raw material for light-based 3D printing,” explains Professor Blasco, who conducts research with his team at the intersection of polymer chemistry, materials science and 3D nanofabrication.

The research is a collaboration between the University of Heidelberg and the Karlsruhe Institute of TechnologyPart of the “3D Matter Made to Order” center of excellence in collaboration with (KIT). Researchers from the Karlsruhe Institute of Technology and the University of Las Palmas de Gran Canaria are also involved.

Source: 3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.