Production process and process process

1. Production process

The entire process of transformation of raw materials into a finished product is called the production process. The production process includes: transport and conservation of raw materials, preparation of production, rough manufacturing, mechanical treatment, heat treatment, assembly, detection, debugging, paint and packaging.

The production process can be divided into: the production process of the entire machine, the production process of a part or a part;

2. Process

During the production process, the shape, the size, the relative location and the nature of the production objects directly modify the manufacturing process of a finished or semi-finished product process, called a process process. The process is the main part of the production process. The main part of the mechanical processing workshop production process (i.e. the method of using mechanical treatment to make the whole process of qualified parts), called process of processing the process of process mechanical treatment; The whole machine) is called the assembly process.

Composition of the mechanical processing process

1 and 1

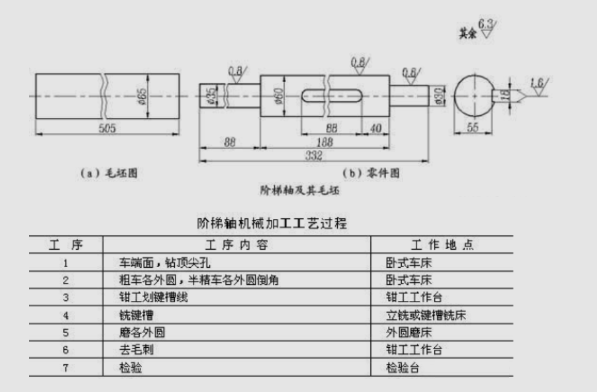

The process refers to the process process that (or a group) workers, part of the process of a part (or at the same time) on a (or a machine-tool). The process is the basic component of the craft road, and it is also the basic unit of the organization of production plans. The mechanical processing process of the scale shaft (below) is indicated in the table below.

Since a worker first finished the two ends of the car on a tool-tool, after having pierced two pointed holes, the second room was replaced. Then, on the same round, after the district of the rough car, the semi -semi -semi -Scar is rounded and the rooms are replaced continuously, the second room is replaced. . If a worker is completed continuously on a tour, after the end of the end of the car, the top of the drill, the exterior circles of the rough car, the exterior circles of the semi -semi -semi -car, etc., Then change the second piece to repeat these content, then some processes will be a process, not two processes.

2. Installation

The part of the part (or the assembly unit) finished after an installation was called installation. In the same process, the part can be installed several times. As shown in Figure 16.1, in process 1, it must generally be installed twice: tighten the outer circle φ65, one end of the car and pierce the top from the top; , the other side of the car and pierce the upper hole.

During treatment, minimize the number of installations to reduce installation errors and save assistance time.

3. Worker

The part of the process which is carried out continuously in the case of the processing surface (or the connection surface during assembly), processing (or assembly), tools, speed and costs n ‘is not changed. Gongbu is the basic unit that constitutes the process.

4

In order to finish a certain part of the process, after tightening at a time, the part (or the assembly unit) and the movement part of the luminaire or the device are the same as each position occupied by the fixed part of the tool and the device. For example, six -way grinding is used for each transposition.

5. Walk a knife

In the same work, if the amount of treatment is large, you should use the same set of knives. It is a knife at a time.

Production program and type of production

1. Production program

The release of the product and the progression plan that companies should produce in the plan are called the production program. The number of qualified products manufactured by the factory is called the annual production program, also known as the annual production. The production program has a decisive impact on the production process and factory management. When preparing the mechanical part processing process, it is necessary to determine the part production program. The part of the production of parts is calculated by the following formula:

N = nn (1 + a + b)

In the formula: n zero-production of the program for parts;

Product production program N;

N-the number of parts in each product;

The spare rate of the α parts;

The average waste of β parts.

2. Type of production

Depending on the size of the product and the production program, depending on the degree of production of companies (or workshops, work sections, teams and workplace), the production of machine manufacturing is generally divided into Three types.

1) Single production

A single manufacturing part (or product), rarely repeated or not repeated, is called unique production. For example, the production of heavy machinery factories or machine repair workshops, several new product tests, etc.

2) Production by lots

The lot of the same parts (or products) is generally a periodically repeated production, which is called production by lots. The number of the same part (or product) invested or production per lot is called lot. Depending on the size of the lot and the characteristics of the product, the production batch can be divided into small lots, production of medium bins and a large number of production.

3) A large production

There are many manufacturing of the same parts (or product). For example, the production of automotive factories and rolling factories generally belongs to a large number of production.

The type of production is mainly determined according to the annual production of the same parts of the treatment. See the table below for the division and the characteristics of the process of various types of production

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.