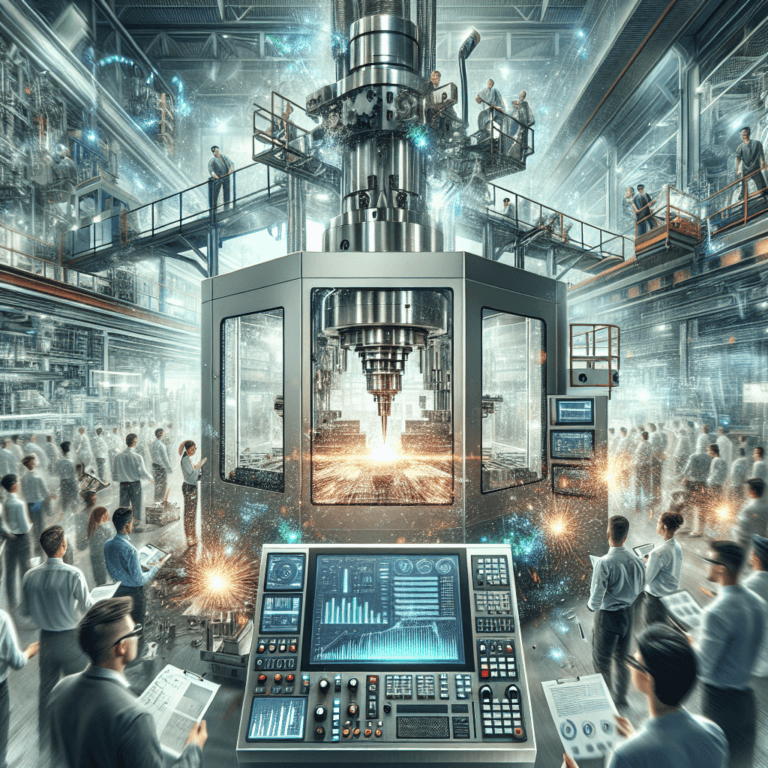

In modern manufacturing, computer numerical control (CNC) machines are at the forefront of innovation, efficiency, and precision. As industries around the world seek to optimize production processes, CNC machining centers offer a unique combination of speed and precision, changing the way components are manufactured. In this comprehensive article, we’ll explore how to maximize efficiency with CNC machining centers, including essential technologies, best practices, and innovative strategies that drive manufacturers to achieve unparalleled productivity.

What is a CNC machining center?

CNC machining centers are automated tools that can precisely machine parts by controlling mechanical motion using programmed commands. Unlike traditional machine tools that require manual adjustments and intervention, CNC machining centers operate on a digital basis, utilizing computer-aided design (CAD) models to manufacture parts with extraordinary precision.

There are many types of these machining centers, including mills, lathes, and milling machines, each designed specifically for a specific application. The versatility of CNC technology allows manufacturers to produce complex geometries and complex designs that are not possible with manual machining.

Advantages of CNC machining centers

Before we dive into strategies for maximizing efficiency, it’s important to understand the core benefits that CNC machining centers offer:

Precision and accuracy: CNC machine tools can achieve micron-level tolerances, ensuring products meet strict quality standards.

automation: After the program is uploaded, CNC machine tools can run with minimal manual intervention, enabling continuous production and reducing labor costs.

Scalability: CNC machining can meet both low- and high-volume production needs, providing the flexibility many manufacturers require today.

Cost effectiveness: While the initial investment costs may be high, these expenses can be offset by long-term savings through reduced scrap rates, reduced labor costs, and increased throughput.

Complex parts production: Advanced CNC machines can produce complex designs and complex geometries, allowing manufacturers to explore new product lines and features.

- consistency: The automated nature of CNC machining ensures that every product produced is identical, greatly reducing the possibility of human error.

Explore the efficiency of CNC machining

Now that we understand the basics of CNC machining, let’s explore specific ways to maximize the efficiency of these machining centers.

Optimize CNC programming

Utilize advanced CAD/CAM software

The integration of advanced CAD (computer-aided design) and CAM (computer-aided manufacturing) software is critical to the efficiency of CNC machine tools. By leveraging sophisticated algorithms, CAM software can optimize tool paths, shorten cycle times and increase overall productivity. Features like Adaptive Machining make the machining process more efficient by adjusting tool paths in real time based on cutting conditions.

Code optimization

An often overlooked aspect of CNC programming is the optimization of CNC code. Efficient programming not only reduces machining time but also minimizes tool wear. Strategies include:

Optimal feed rates and speeds: Adjusting feed rates and spindle speeds based on material type and tooling can significantly reduce cycle times.

Tool path minimization: Reducing unnecessary machine movement can reduce overall processing time. implement strategies such as "the climb" and "traditional" Milling can play a key role here.

- Subroutine usage: Utilize subroutines to perform repetitive tasks to simplify the programming process and reduce overall program length.

Simulation and testing

CNC programming should be rigorously tested before actual machining begins. By running simulations, manufacturers can optimize their programs, identify potential collisions, and simulate part handling without wasting raw materials or using machine time inefficiently.

Maintained for consistent performance

Regular preventive maintenance

Maintenance is critical to ensuring that CNC machining centers operate at peak efficiency. Regular maintenance can extend the life of your machine and maintain operational accuracy. A well-structured maintenance plan should include:

Cleaning and lubrication of moving parts to prevent wear and corrosion.

Calibration check To ensure the accuracy of machine action.

- Inspection of tools and tool parts Replace or polish worn items before they impact production.

Using IoT for predictive maintenance

The rise of the Internet of Things (IoT) is enabling manufacturers to take advantage of predictive maintenance technology. Sensors placed on machines can collect real-time data and provide insights into machine performance and potential failures. This proactive approach not only minimizes downtime but also improves operational efficiency.

Employee training and engagement

Comprehensive training program

The efficiency of a CNC machining center depends largely on the expertise of the operator. Therefore, investing in training programs is crucial. Regular seminars and certifications in CNC programming and machine operation empower operators and ensure they are up to date on the latest technology, trends and operating methods.

Additionally, cross-training employees on different CNC machines can enhance flexibility, allowing operators to easily switch tasks when production demands fluctuate.

Encourage a culture of continuous improvement

Creating a workplace culture focused on continuous improvement leads to innovation in processes and practices. Encourage employees to share insights and suggestions for optimizing operations. Implementing employee feedback can significantly improve efficiency and morale.

tool strategy

Choose the right tool

Choosing the right tool is crucial for efficient machining. Operators must consider:

Material Compatibility: Different materials require specific types of cutting tools. Ensuring compatibility optimizes performance and reduces wear and tear.

Tooling system: Modular tooling system allows changes to be made quickly and easily, minimizing downtime between setups.

- Edge geometry and coating: Specialized coatings enhance tool performance and extend tool life, reducing replacement frequency.

Utilize automatic tool changing system

Automatic Tool Changer (ATC) allows the machine to change tools without human intervention, significantly reducing downtime. This automation streamlines the production process, thereby increasing efficiency and reducing cycle times.

Simplify workflow

Lean Manufacturing Principles

Lean manufacturing practices focus on reducing waste and optimizing processes. Implementing lean principles in CNC machining can significantly improve efficiency. Technologies include:

Value stream map: Analyzing the flow of materials and information can help identify inefficiencies and areas for improvement.

Just-in-time (JIT) production: JIT minimizes inventory levels by producing goods based on current customer demand, thereby reducing wait times and improving responsiveness.

- improve: The philosophy of continuous improvement encourages small, incremental changes that, over time, can lead to significant efficiency gains.

Workflow automation

Integrating workflow automation tools can also streamline operations. For example, setting up an automated scheduling system ensures machines are running at optimal times and reduces inactivity time.

Effective layout and workflow design

The physical layout of the processing area can significantly affect efficiency. Designing a factory with optimal workflow minimizes moving and shipping time. Consider creating “cells” for specific machining operations to streamline processes and enhance collaboration.

Embrace emerging technologies

Advanced robotics and CNC integration

The combination of CNC machining centers and robotics has been proven to maximize output and efficiency. Robots can handle tasks such as loading and unloading materials, allowing operators to focus on more complex tasks.

Robotic arms can also manage multiple CNC machines, further increasing productivity and reducing operational bottlenecks associated with manual intervention.

Artificial Intelligence in CNC Machining

Artificial intelligence-driven systems are beginning to play a role in optimizing machining processes. Intelligent algorithms can monitor machine performance in real time, predict failures and recommend adjustments, allowing manufacturers to increase productivity while maintaining quality.

Augmented reality for training and maintenance

Leveraging augmented reality (AR) for training and repair processes can provide visual aids to help operators quickly and accurately diagnose problems, reducing downtime. AR applications can enhance understanding of complex processes, making operators more efficient.

sustainable development practices

Reduce waste and scrap

Sustainable manufacturing practices should be integrated into CNC machining processes. Implement strategies such as:

Recycled materials: Ensure proper recycling of scrap metal and other scrap materials to reduce environmental impact.

- Energy saving machine: Investing in energy-efficient CNC machine tools reduces operating costs and helps achieve sustainability goals.

Sustainable supply chain practices

Working with suppliers who adhere to sustainable practices can make the production process more efficient. Working with environmentally conscious suppliers reduces the risks associated with resource depletion and fosters efficient supply chains.

in conclusion

Maximizing the efficiency of your CNC machining center requires a multifaceted approach that combines technology, skilled personnel and innovative practices. From advanced programming techniques to ongoing maintenance and adoption of new technologies, each element plays a vital role in increasing productivity and ensuring competitive advantage in today’s manufacturing world.

As the industry continues to evolve, manufacturers must adopt a continuous improvement mindset that encourages innovation and adaptation. By prioritizing the efficiency and sustainability of CNC machining processes, manufacturers can thrive in an increasingly demanding market, driving quality and profitability forward.

FAQ section

What is the average lifespan of a CNC machine tool?

The service life of a CNC machine tool varies greatly depending on use, maintenance and technology. On average, a well-maintained CNC machine tool can last 10 to 25 years, sometimes even longer, depending on the severity of its application.

How can you reduce downtime in machining operations?

There are several strategies to reduce downtime, including implementing preventive and predictive maintenance, optimizing tool usage, utilizing automated tool changers, and employing effective scheduling practices. Regular operator training in troubleshooting techniques can also minimize downtime.

What materials can be processed using CNC machines?

CNC machines can machine a variety of materials, including metals (e.g., aluminum, steel, titanium), plastics, wood, and composites. The choice of processing method depends on the material properties and the desired results.

What is the difference between CNC milling and CNC turning?

CNC milling involves rotating a cutting tool relative to a fixed workpiece to create the desired surface shape, while CNC turning rotates the workpiece while the fixed tool removes material from the workpiece. Each process has its specific applications and advantages.

How do I choose the right CNC machine for my business?

Choosing the right CNC machine requires consideration of a variety of factors, such as the materials you plan to use, the complexity of the parts you want to produce, throughput, and budget constraints. Consulting with industry experts or conducting a thorough needs analysis can facilitate the decision-making process.

By addressing these important aspects of CNC machining and staying current on emerging trends and technologies, manufacturers can significantly enhance their operations while achieving greater efficiency and effectiveness in their processes.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.