Mastering CNC Production Machining: A Complete Guide for Beginners

Introduction to CNC production and processing

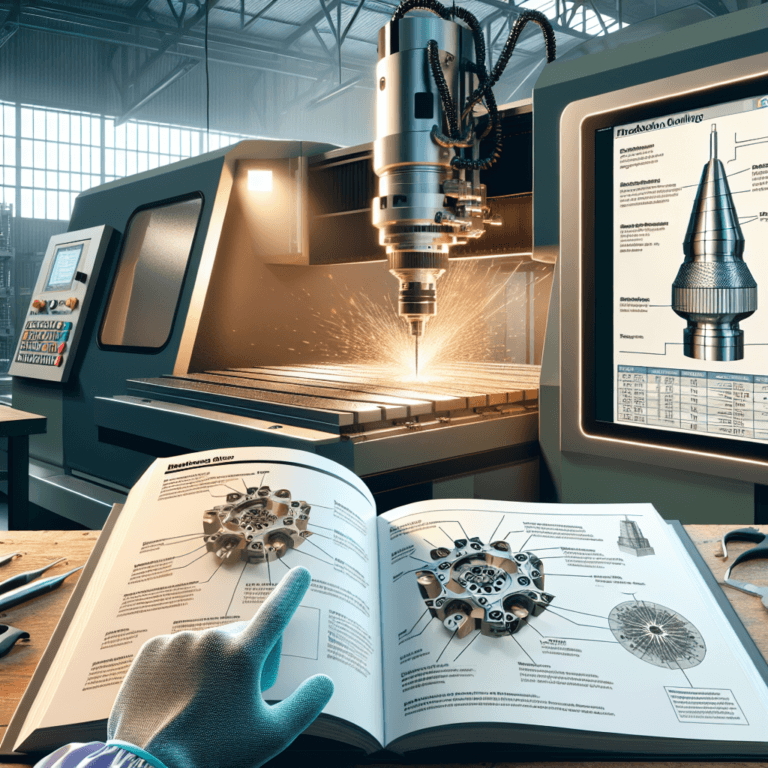

In the manufacturing sector, CNC (computer numerical control) production processing has become a key technology that improves precision, efficiency and the overall quality of finished products. CNC production machining involves the use of computer systems to control machine tools to enable precise engraving, drilling, milling and cutting of materials ranging from metals to plastics. As the industry continues to evolve, understanding this technology is critical for those seeking manufacturing, engineering or design positions.

In this comprehensive guide, we’ll delve into the basics of CNC production machining, exploring its applications, benefits, and skills needed to master the field. Our journey will cover everything from the basic concepts of CNC technology to the intricacies of setting up your own CNC machine operation, making this guide a great resource for beginners.

Learn about CNC machining technology

H2: What is CNC production and processing?

CNC production machining is a method of using computer control to operate machinery, helping to manufacture parts with precision and automation. Unlike traditional machining methods that rely heavily on manual intervention, CNC machining uses computer programs to control the movement of the machine, which not only minimizes human error but also improves the repeatability and consistency of production.

H2: A brief history of CNC machining

The origins of CNC technology can be traced to the 1940s and 1950s, when the first numerically controlled (NC) machine tools were developed. These machines relied on punched tape for programming, which was rudimentary compared to today’s digital systems. With the advancement of computer technology, the first CNC machine tools appeared in the 1960s, revolutionizing the manufacturing process.

H2: Type of CNC machine tool

There are many types of CNC machine tools, each tailored to specific machining tasks. Here are some of the most commonly used types in production settings:

CNC milling machine: Ability to perform a variety of tasks such as drilling, milling and boring. They can be used with a variety of materials and are versatile.

CNC lathe: CNC lathes are ideal for producing cylindrical parts because they rotate the workpiece against a cutting tool, allowing complex shapes to be created.

CNC milling machine: CNC milling machines are primarily used to cut wood, composites, plastics, and metals and operate at a faster speed compared to CNC milling machines.

CNC plasma cutting machine: These machines utilize a plasma torch for the cutting process and are a popular choice for cutting sheet metal with high precision.

- CNC laser cutting machine: Like plasma cutters, laser cutters use high-power lasers to achieve fine cuts and intricate designs in a variety of materials.

H2: Advantages of CNC production and processing

CNC production machining offers numerous advantages that make it the first choice in various industries:

accurate: CNC machines can operate with tolerances as low as 0.001 inches, significantly improving the quality of manufactured parts.

efficiency: Once the design is complete, the CNC machine can run continuously, significantly reducing production time.

Scalability: CNC machining can easily adapt to changes in production volumes, making it suitable for both low- and high-volume production.

Reduce waste: Automation allows for more precise cuts that minimize material waste, resulting in cost savings.

- Versatility: CNC machines can perform a variety of operations on different materials, making them suitable for a variety of applications.

Introduction to CNC production processing

H2: Essential skills for CNC machinists

To excel in CNC production machining, certain skills and knowledge areas are critical:

Technical skills: Understanding machine setup, tool usage, and programming languages such as G-code is critical.

Mathematical ability: Basic mathematical skills and knowledge of geometry are essential for calculations related to machining dimensions and tolerances.

Attention to detail: Precision is at the heart of CNC machining; intense attention to detail ensures high-quality results.

Problem-solving skills: CNC machinists must be able to solve problems that arise during production.

- Computer knowledge: Familiarity with CAD (computer-aided design) and CAM (computer-aided manufacturing) software is essential for programming CNC machine tools and optimizing workflow.

H2: CNC machining workflow

Understanding the CNC machining workflow is crucial for new machinists. General steps of the process include:

Design stage: Use CAD software to create detailed designs of target parts.

Convert to G code: CAM programs convert CAD designs into G-code, which serves as the language of the CNC machine tool.

Machine settings: Properly calibrate CNC machines, including tool installation and workpiece positioning.

Processing technology: CNC machines perform programming operations to create parts.

- Quality control: Finished parts are inspected for accuracy and compliance with tolerances before being delivered for use.

Choose the CNC machine that suits your needs

H2: Choose the right CNC machine tool

Choosing the right CNC machine depends on a variety of factors, primarily the specific application and materials you want to use.

Material Compatibility: Consider what materials need to be processed. Some machines are designed specifically for metal, while others are better suited for plastic or composite materials.

Part complexity: The complexity of the part determines the type of machine required. Complex designs may require multi-axis machines for precise manipulation.

- Budget constraints: Assess your budget for purchasing and maintaining machinery, keeping in mind that advanced CNC machines may require more upfront investment.

H2: CNC machine tool maintenance

Regular maintenance is essential to ensure that CNC machine tools operate efficiently and extend their service life. Basic maintenance practices include:

Regular cleaning: Keep machines and work areas clean to avoid contamination. Regular removal of chips and debris can prevent damage to components.

lubricating: Lubricate moving parts regularly to minimize wear.

Calibration check: Regularly check machine calibration to ensure components are operating within specified tolerances.

- Software updates: Keep your machine software updated to benefit from the latest features and improvements.

H2: CNC machining software

There are several software programs available to facilitate CNC production machining, each addressing specific needs:

CAD software: Tools such as AutoCAD and SolidWorks help create detailed designs of components.

Cam software: Software such as Mastercam and Fusion 360 help convert CAD designs into G-code for machine processing.

- CNC post-processor: These tools are necessary to convert CAM data into machine-specific G-code.

The future of CNC production processing

H2: Innovation in CNC machining

The CNC production and processing landscape is constantly evolving, with innovation driving improvements in efficiency and capabilities. Some of the latest trends include:

Additive Manufacturing: The integration of 3D printing technologies is creating hybrid machines that combine subtractive and additive methods.

Automation and Robotics: Increased automation can reduce labor costs and increase productivity, often using robotic arms to load and unload materials.

Smart factory: The Internet of Things (IoT) is being embedded in CNC operations, enabling real-time monitoring and predictive maintenance, further streamlining operations.

- Advanced materials: The ability to use new advanced materials such as composites and alloys expands the scope of CNC machining applications.

in conclusion

CNC production machining is the cornerstone of modern manufacturing, improving efficiency and precision in numerous applications. From understanding the basics of CNC technology to overseeing complex workflows and careful machinery selection, new entrants to the field can set themselves up for success. As technology continues to innovate and change, it is critical for machinists, engineers, and manufacturers to keep up with technological advancements. Mastery of CNC production machining allows individuals to gain valuable skills in a competitive job market, ultimately contributing to the continued advancement of the manufacturing process.

FAQ section

Q1: What is the difference between CNC processing and traditional processing?

Answer: CNC machining uses computer programs to automate machine tool operations, thereby improving accuracy and efficiency. Traditional machining relies on manual controls, which can involve a higher risk of human error.

Q2: What types of materials can CNC machine tools process?

A: CNC machines can process a variety of materials, including metals (aluminum, steel, titanium), plastics, wood, and composites, depending on the machine type.

Q3: What is G-code and why is it important?

Answer: G-code is a programming language used to control CNC machine tools. It determines the movement, speed and flow of the machine and is essential for performing precise machining tasks.

Q4: How to start learning CNC machining?

A: Start by gaining knowledge through resources such as online courses, technical schools, and hands-on training. Become familiar with relevant software tools and seek internship opportunities to gain hands-on experience.

Q5: What career opportunities are there in CNC production and processing?

A: Career paths include CNC machinist, programmer, operator, mechanical designer, quality control inspector, manufacturing engineer, and more.

By following this guide and taking advantage of available resources, you can embark on a rewarding journey into the world of CNC production machining and acquire the skills needed in today’s advanced manufacturing world.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.