The Future of Mold Making: Unlocking High-Speed Production with FF/CAM Software

In this era of rapid technological advancement, the mold industry is evolving at an unprecedented pace. With the increasing demand for precision, complexity, and high-efficiency molds, production companies are required to deliver high-quality products in shorter cycles. However, this comes with a new set of challenges for manufacturers, including shorter production cycles, higher quality demands, and the need for more advanced processing equipment and software.

The Development of FF/CAM Software

To meet these challenges, Makino Software Department has developed an innovative FF/CAM software, a result of over 30 years of research and development. This software is designed to cater to the specific needs of the mold-making industry, providing a range of processing strategies for high-speed machining.

What is FF Treatment Technology?

FF treatment technology is a unique approach to processing that involves the rapid, instantaneous discharge of cutting point fleas, resulting in high-quality treatment surfaces. This technology is particularly well-suited for high-speed processing, which requires precise control and efficient operation. The software is designed to meet the demands of high-speed machining, with features such as real-time interference monitoring, automatic tool path optimization, and high-speed cutting experience values.

Key Features of FF/CAM Software

The FF/CAM software offers a range of features that cater to the specific needs of the mold-making industry, including:

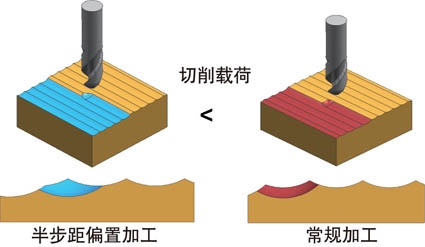

Half-Stage Bias Function: This feature allows for effective reduction in cutting load, making it ideal for rough processing. By applying the half-stage bias function, manufacturers can achieve faster processing times and improved results.

Three-Dimensional Spiral Machining Function: This feature enables the use of three-dimensional spiral machining, which can improve processing efficiency and reduce the need for frequent tool changes. With this feature, manufacturers can achieve smoother, more precise results.

Real-Time Interference Monitoring: FF/CAM software provides real-time monitoring of tool support, ensuring that manufacturers can avoid tool collisions and optimize processing times.

Automatic Tool Path Optimization: This feature allows for automatic optimization of tool paths, ensuring that manufacturers can achieve the most efficient processing times and results.

High-Speed Cutting Experience Values: The software provides high-speed cutting experience values, enabling manufacturers to optimize processing conditions, reduce cutting heat, and prolong tool lifespan.

Programmed Material Removal Rate: This feature allows users to program material removal rates, enabling precise control over processing parameters and resulting in improved quality and efficiency.

Tool Path Expansion and Surface Filling: FF/CAM software provides for tool path expansion and surface filling, ensuring that complex surfaces can be efficiently processed.

Real-Time Cutting Condition Monitoring: This feature allows manufacturers to monitor cutting conditions in real-time, enabling quick adjustments and optimal processing results.

- Post-Processing Function: The software includes a post-processing function that enables manufacturers to analyze and optimize processing parameters for optimal results.

The Future of Mold Making with FF/CAM Software

In today’s fast-paced and competitive market, manufacturers require software that can keep up with the demands of high-speed processing. FF/CAM software is designed to meet these demands, providing a range of processing strategies and features that cater to the needs of the mold-making industry.

With FF/CAM software, manufacturers can achieve:

- Faster processing times

- Improved quality and precision

- Increased efficiency

- Reduced tool wear and breakage

- Optimized processing parameters

- Real-time monitoring and control

In conclusion, FF/CAM software is the ideal solution for manufacturers seeking to stay ahead of the competition in the rapidly evolving mold-making industry. With its advanced processing strategies and features, this software is designed to meet the demands of high-speed processing, providing manufacturers with the tools they need to deliver high-quality products in shorter cycles.