Mohou.com laser cutting material introduction: copper, click to learn more about the performance of copper

T2 copper refers to a copper-silver alloy, in which the copper + silver content of copper is >99.9O, and there is no requirement for phosphorus.

It has good electrical conductivity, good thermal conductivity, good corrosion resistance and processing properties, and can be welded and brazed. Contains fewer impurities that reduce electrical and thermal conductivity. Traces of oxygen have little effect on electrical conductivity, thermal conductivity and processing properties, but can easily cause them.“Hydrogen disease” means that it is not suitable to be processed (annealed, welded, etc.) and used in a high temperature reducing atmosphere (such as >370°C).

Main uses:

Used as conductive, thermal conductive and corrosion resistant equipment. Such as wires, cables, conductive screws, detonators for blasting, chemical industry Evaporators, storage containers and various pipes.

Classification and specifications:

Introduction to T2 copper plate thickness (whole length can be customized by zero cutting)/mm | |||||

0.8 | 1 | 1.2 | 1.5 | 2 | 3 |

4 | 5 | 6 | 8 | 12 | 15 |

20 | 25 | 30 | 35 | 40 | 45 |

50 | 55 | For more specifications, please contact customer service | |||

thickness0.5-0.8 is the thickness of the roll material/thickness above 0.8 is the full page: 600*1500mm | |||||

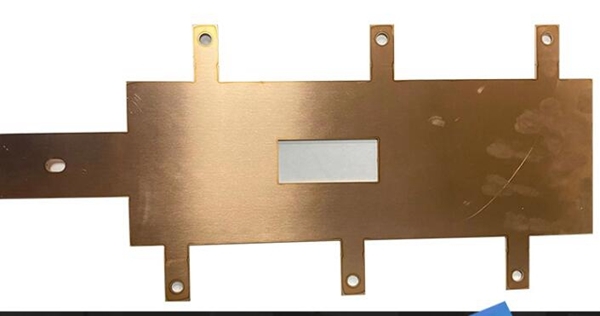

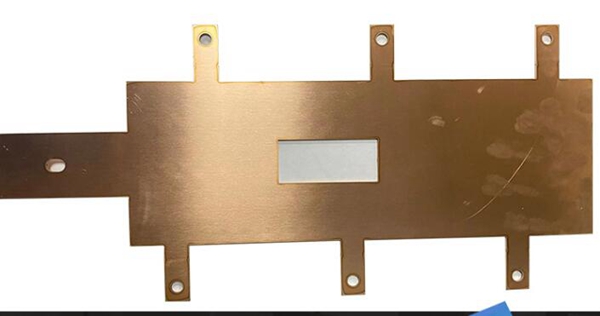

Case:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.