In the realm of advanced manufacturing, the phrase "light-forged cutting edge" takes on a double meaning. Not only does it refer to the enhanced precision and speed of modern laser cutting machines, but it also encapsulates the evolving safety measures that have simultaneously become a cornerstone of this technology. As industries across the globe pivot towards laser technology for their metal cutting needs, the marriage of precision and safety is quickly defining the landscape of metalworking.

The Evolution of Metal Laser Cutting Machines

Metal laser cutting has undergone a substantial evolution over the past few decades. The technology’s leap from conventional cutting methods—like oxy-fuel and plasma cutting—has radically redefined expectations concerning accuracy, speed, and versatility. Today’s laser cutting machines utilize high-powered lasers to melt, burn, or vaporize materials, leaving behind a clean cut that is often more precise than traditional methods could ever hope to achieve.

Laser cutting machines operate across various materials, including stainless steel, aluminum, brass, and even specialized metal alloys. Each metal presents unique challenges and advantages, but advancements in laser technology allow operators to push these boundaries further than ever before.

The Precision Dance of Laser Cutting

At the heart of laser cutting technology lies an intricate dance of precision. This dance begins with the setup of the laser machine, which often leverages computer numerical control (CNC) technology for its operations. The precision achieved can be credited to several factors:

1. High Beam Quality

Modern laser cutting machines often utilize fiber lasers, which have a smaller, more concentrated beam compared to traditional CO2 lasers. The increased beam quality allows for finer detail and smoother edges, enhancing the overall aesthetics and functionality of the cut pieces.

2. Speed and Efficiency

The speed at which a laser can cut through metal is astounding. Unlike traditional techniques that require multiple passes, laser cutting often accomplishes tasks in single but rapid movements. This swift operation minimizes operational downtime and maximizes productivity, a crucial factor in highly competitive industrial environments.

3. Complex Geometries

Laser cutting technology excels in producing complex shapes that would be impossible to achieve with traditional cutting methods. Manufacturers can create intricate designs, patterns, and features with precision correctly aligned to tight tolerances. This capability makes laser cutting ideal for industries such as automotive, aerospace, and construction, where such specifications are key.

4. Minimal Material Waste

Another significant advantage of laser cutting is its ability to operate without substantial material waste. The focused beam and cutting pattern mean that scrap materials are minimized, translating to cost savings for manufacturers and a lower environmental impact.

Safety First: The New Safety Movement

As laser cutting technology has advanced, so too have safety measures. The high-speed operation of these machines, paired with their powerful and sometimes dangerous lasers, means that a robust safety framework is essential. The safety movement within the laser cutting industry aims to address potential hazards while promoting a safe working environment.

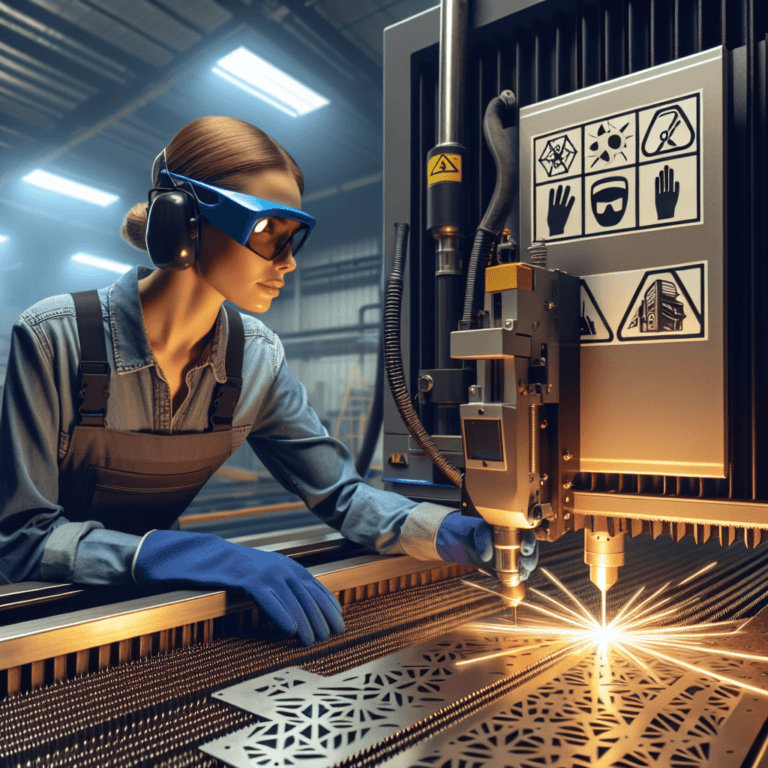

1. Protective Equipment

Operators are now required to wear protective gear designed explicitly for laser cutting environments. This includes specialized eyewear that shields against the intense light emitted, as well as flame-resistant clothing to protect against thermal injuries.

2. Machine Safeguards

Modern metal laser cutting machines are equipped with various safety features to prevent accidents. This includes covering the laser cutting head and enclosing the entire cutting area to shield the operator from potential exposure to the laser beam. Additionally, emergency stop buttons are strategically located to provide instant access in emergencies.

3. Training and Protocols

Safety training is becoming mandatory across industries employing laser cutting technology. Operators are required to undergo comprehensive training that includes understanding how to operate the machine safely, recognizing potential hazards, and responding to emergencies effectively.

4. Automated Monitoring Systems

Advanced laser cutting machines often feature automated systems that monitor performance and safety. These systems can detect anomalies in operation and immediately alert operators or halt processes to prevent accidents. Integrating such technology represents the industry’s commitment to continuous improvement in safety standards.

The Future of Light-Forged Metal Cutting

The future of laser cutting technology is bright, with continuous advancements leading down new paths of innovation. As we look ahead, several trends are poised to shape the industry further:

1. Integration of AI and IoT

The integration of artificial intelligence (AI) and the Internet of Things (IoT) into metal laser cutting machines is on the horizon. These technologies promise to enhance precision further, predict system failures, and optimize cutting processes by analyzing real-time data.

2. Sustainable Practices

As environmental concerns take center stage globally, the metalworking industry will need to adopt sustainable practices more aggressively. Laser cutting’s inherent efficiency and reduced waste production are positions that can help manufacturers transition towards a more sustainable future.

3. Advanced Materials

New materials and alloys are continuously being developed, and laser technology can adapt quickly to cutting these advanced materials. As industries search for solutions that offer strength, lightweight properties, and durability, laser cutting will be crucial in efficiently processing these new materials.

4. Enhanced Personalization

With the rise of customization in manufacturing, laser cutting technology will play a vital role in enabling personalized production. The high precision capabilities of lasers make it possible to offer tailored solutions in various industries, from architecture to consumer products.

Concluding Thoughts

The light-forged cutting edge of laser cutting technology offers a promising blend of precision, speed, and safety, revolutionizing the metal cutting industry. From its evolution to its current state, this technology has continually adapted to meet the increasingly complex needs of manufacturers while placing an unwavering emphasis on safety.

As we look ahead, embracing future innovations such as AI, sustainable practices, and advanced materials will ensure that the dance of precision and safety continues to define the landscape of metal laser cutting machines. By investing in both technology and safety, industries can not only improve their output but ensure that their workforce operates in an environment designed for well-being and efficiency.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.