We’ve already talked about some tool handle interfaces. In this issue we continue to address the topic of tool handles and briefly talk about the classification of tool handles. In short, they are divided into several categories:Spring tool holders, heat shrink tool holders, hydraulic tool holders, other tool holders.

1

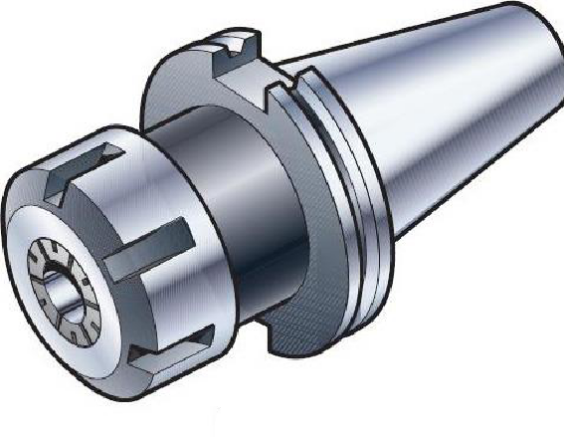

spring knife handle

Spring knife handles, also called ER knife handles, are widely used in practical applications because they are easy to install tools and have strong tool holding power (of course, they are also more affordable). Mainly uses taper collet tightening and loosening to connect, disassemble and secure tools. Spring-loaded tool handles come in different shapes to hold cylindrical workpieces or tools. For this reason, spring-loaded tool holders are sometimes used on lathes. There are two main types of spring-loaded tool holders on CNC machine tools: “pull-in” and “pull-in”.

When using the pull-out method, twist the nut on the front of the pliers and push the pliers in. The pliers are tightened and the tool is tightened.

The pull method uses the screw at the bottom of the collet to pull the collet inward to tighten the collet, thereby firmly gripping the tool.

2

Heat Shrink Tool Holder

Heat shrink tool holders are tool holders that use the properties of metal materials to expand when heated and shrink when cooled. The working process of the heat shrink tool holder is as follows:

Firstly, the tool holder is heated by a heat shrinking machine; then, the tool is inserted into the inner diameter of the tool holder which has expanded due to heating; then the tool is cooled with water or other coolants; The inner diameter of the shank shrinks and the tool is tightened.

German Daibo heat shrink machine

German Bilz heat shrink machine

In order to complete this process, you need to prepare a heat shrink machine. This method has higher rigidity and runout accuracy than other tool holders and is effective for machining hard materials and high-precision machining using small diameter tools.

By using a heat shrink machine, the skill level of the operator does not depend and the high repeatability of the connection is also a key advantage of this method.

3

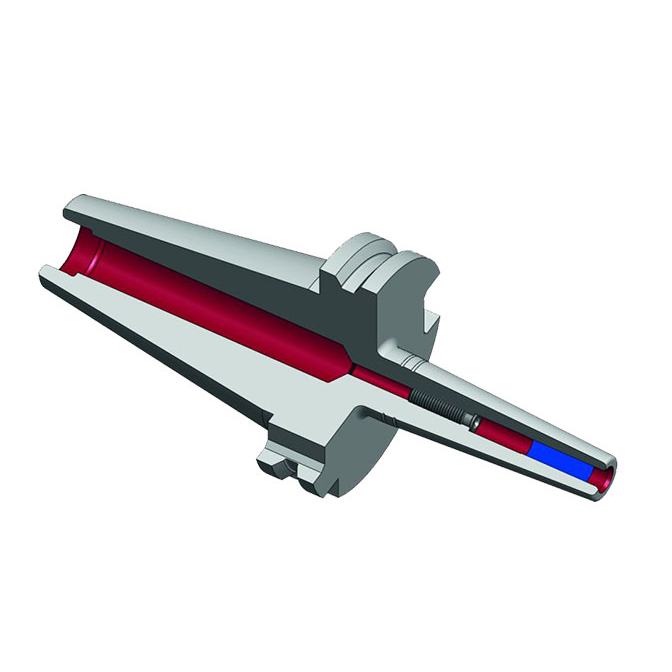

Hydraulic tool holder

The principle of a hydraulic tool holder is similar to that of a hydraulic cylinder. Oil pressure is adjusted by screws to pressurize and tighten the tool. The operator can easily hold the tool using a hex wrench. Hydraulic tool holders offer extremely high runout accuracy and are generally suitable for finishing operations.

In addition, oil has a great ability to absorb vibration energy and reduce vibrations generated during machining. However, there are some rigidity issues compared to other types of tool holders, such as spring-loaded tool holders (ER tool holders). Therefore, tool holder manufacturers are working to develop hydraulic tool holders with greater rigidity.

4

Other handles

In addition to the three types of tool holders shown above, there are many other types of tool holders for machining centers, such as cutting heads for mounting indexable milling inserts, drill chucks for hold drill bits on bench drills (top figure), tool holders. for tapping, boring bar for reaming, etc.

Of course, the angle head is also one of the types of tool holders for machining centers. An angle head is a different structure from a traditional tool holder and can change the machining direction of the tool to a specific angle, allowing a new axis to be added to an existing machining center for machining. Therefore, by effectively using the angle head, various machining operations can be carried out by simply clamping the workpiece once on the workbench, thereby improving machining efficiency.

Here, the editor wishes to highlight the choice of angle heads. Generally, angle head brands are divided into Chinese, Taiwanese, European and Japanese categories. For products such as angle heads, it is recommended to choose the brand because it can be used. in the treatment. The angle heads are all processed with high precision. It is recommended not to try unbranded products easily.

The choice of accessories inside the angle head also determines the price of the product itself. Don’t be tempted by an angled head that costs around €5,000. Fans who have been in contact with it have encountered such a problem. In addition, the experience of angle head manufacturers should also be taken into account. Do not easily entrust important projects to some inexperienced manufacturers. Moreover, the last point is the budget and delivery time that customers need to consider. It is also the key to the success of many projects. In many cases, an unreasonable budget is doomed to the loss of the project.

The speed increasing spindle is also a tool holder that improves spindle performance. It is installed on the spindle of an existing machining center to increase spindle speed. Even in finishing operations requiring high spindle speeds, existing machining centers can operate with speed-increasing spindles.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.