Copper, sand, aluminide… We talked about many of the materials used in 3D printing. Today we are interested in titanium. It is a transition metal and is never found in its pure state in nature. To extract it, minerals such as rutile (TiO2) and ilmenite (FeTiO3) are used in a complex process.

Although this process can produce pure titanium, its energy costs remain high. The purity of the metal produced generally reaches99.9%, often alloyed with other metals to create higher performance alloys. Due to its properties, titanium has become the material of choice for additive manufacturing in fields such as medicine, aerospace and automotive. What are its advantages and features? What 3D printing technologies can we use?

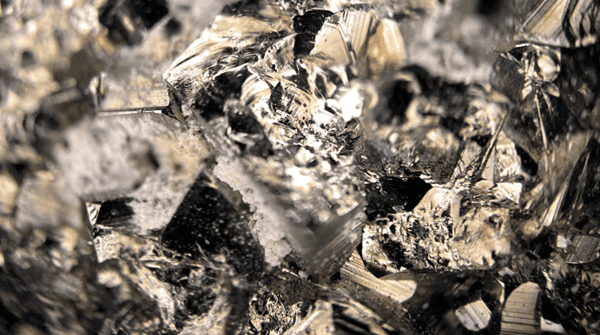

Photo credit:Freepik

What are the characteristics of titanium?

Titanium, withSymbolized by Ti, with atomic number 22, it is a material appreciated for its practical and multifunctional properties. It is known for its light weight, high strength, low toxicity and high corrosion resistance, making it suitable for a variety of applications. Additionally, it is almost as strong as steel but about 40% lighter, making it particularly useful for making parts that are both lightweight and durable. Titanium is also resistant to salt water, chemicals and abrasion, making it an ideal material for extreme environments. In addition to its mechanical properties, it has good thermal properties and can withstand high temperatures up to 600°C. On the contrary, it remains stable even at very cold temperatures.

This material is difficult to process, particularly due to its low thermal conductivity. As with CNC machines, much of the heat generated during machining is retained by the machine, which can lead to rapid wear. Additionally, machining often generates large amounts of waste due to material removal. Faced with these issues, many companies are turning to more efficient methods of producing titanium parts. Therefore, the metal3D printing seems to be a promising solution.

Photo credit: Additive Manufacturing Materials

used forDifferent 3D printed titanium alloys

As mentioned previously, titanium is commonly found inIt is used as an alloy in 3D printing, but thanks to its biocompatibility, pure titanium can also be extracted for specific applications, such as in the medical field. In 3D printing, various titanium alloys are used, the most common being Ti6Al-4V grade 5 (Ti64), which is a blend of titanium, aluminum and vanadium valued for its resistance to heat and corrosion. Other alloys include Ti6Al-4V grade 23, suitable for prosthetics and medical implants, and the stronger, oxidation-resistant Beta 21S titanium, used in orthopedic implants and aerospace engines. Cp-Ti (pure titanium) is also used in the medical field due to its compatibility with the human body. Finally, TA15 alloy, composed of titanium, aluminum and zirconium, is widely used to manufacture high temperature resistant parts in aviation and engines.

Titanium alloys are used inThe field of 3D printing is more popular than that of pure titanium. Although pure titanium is known for its light weight, corrosion resistance and biocompatibility, it also has certain limitations that sometimes reduce its effectiveness. In fact, its relatively low toughness, hardness, and fatigue resistance can pose problems in applications that require the material to withstand high loads and repeated stress.

Image source:Come to fruition

Which ones to use3D printing technology?

existIn 3D printing, titanium is generally used in the form of metal powder or wire, depending on the technology chosen. Various technologies allow printing on titanium, providing various solutions for manufacturing parts. The most common is concentrated energy deposition (DED). In this process, titanium is deposited in powder or wire form and then melted using an energy source such as a laser. Another popular method is laser powder bed fusion (L-PBF), also known as DMLS or SLM. The technology uses lasers to melt particles of metal powder layer by layer to create high-precision titanium parts, such as those made from the alloy Ti6Al4V.

Electron beam fusion (EBM printing) is also used to print titanium. It works on a different principle than lasers, using electron beams in a vacuum environment, and is particularly suitable for manufacturing titanium parts requiring high strength, such as those used in the aerospace sector. Finally, powder-bonded 3D printing (binder jetting) is another method in which titanium powder is bonded to a binder before solidifying through a sintering process.

titaniumWhile 3D printing holds great promise, it also presents some challenges that are worth mentioning. First, production costs are higher due to the price of titanium alloys, which are more expensive than other materials used for additive manufacturing. This cost is also due to the complexity of the printing process and the need for post-processing of parts. Additionally, fewer titanium alloys are available for 3D printing than other metals, which can complicate sourcing and increase costs. Finally, after printing, titanium parts often require careful post-processing, such as support removal, heat treating, and polishing, to achieve the desired quality. These additional steps not only increase production time, but also costs.

Titanium metalWhat are the applications of 3D printing?

In the aerospace sector, titanium3D printing technology is already being used to manufacture key components including turbine blades, brackets and structural parts. The metal is valued for its unique combination of lightness, strength and resistance to extreme temperatures. In the medical field, titanium has long been used due to its biocompatibility and corrosion resistance. From prosthetics to personalized implants, this technology is transforming the medical field by providing better results and reducing surgical time, as demonstrated by the example of implants produced by Amnovis.

Titanium implants produced by Amnovis (Image: Amnovis)

The automotive industry is also increasingly adopting titanium3D printing to reduce vehicle weight and improve fuel efficiency. This technology is used to manufacture engine parts, exhaust systems, suspension components and even chassis parts. Finally, it also extends to other industrial fields such as tooling, formwork and fixing. Indeed, it makes it possible to create complex tools and structures adapted to specific needs.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.