01

introduction

As an advanced processing tool, laser plays an increasingly important role in the field of industrial welding. Although traditional laser welding technology can control these defects to a certain extent, its effect is often limited by fixed welding parameters and processes. In recent years, the emergence of laser swing welding technology has brought new solutions for welding defect control. By introducing laser beam oscillation during the welding process, this technology can significantly improve weld pool dynamics, thereby optimizing weld quality. Swing laser welding technology is mainly based on the precise control and swing technology of the laser beam to achieve efficient and high-quality welding. The application of laser welding technology can make laser welding more widely used. For larger parts and parts with wider weld seams, efficient and precise laser welding can be achieved, that is, the basic process and assembly precision of the product are relaxed.

02

Definition of laser swing welding

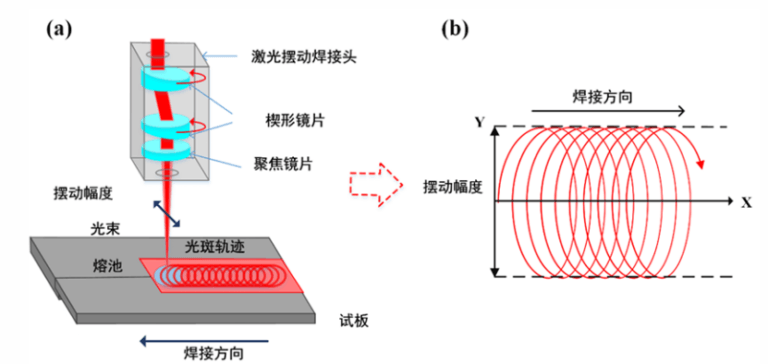

During the welding process, the laser beam is aimed quickly and precisely to cover the entire welding area. When the beam moves in the direction of the weld, it oscillates simultaneously in various shapes such as circular, figure 8 and spiral, as shown in Figure 1. This oscillation not only achieves more uniform heating, but also effectively reduces welding defects such as vents and cracks.

Figure 1. Schematic diagram of the laser oscillation welding process.

(a) Laser welding with IPG D50 welding head,

(b) Trajectory of the light point in circular oscillation mode.

03

Characteristics of laser swing welding

With the development of technology, oscillating laser welding technology has also launched a variety of types according to functions and needs, including laser galvanometer scanning heads, welding oscillating heads, etc., to adapt to the welding needs of different industries. Rotating the beam through a laser-specific pivoting welding head not only expands the processing range, but also increases the weld width tolerance, thereby improving weld quality. Swing laser welding has the following characteristics:

(1) Uniform heat supply: Spin welding can achieve uniform heating of the weld by changing the position of the welding heat source and avoid the problem of thermal stress concentration during the welding process.

(2) High weld quality: Through uniform heat input, oscillation welding can achieve more uniform and stable weld quality and reduce the occurrence of welding defects.

(3) Wide applicability: Swing welding is suitable for various materials and welding positions, and can be used for manual welding and automated welding processes.

Improve production efficiency: Swing welding can reduce welding deformation and reduce welding residual stress, thereby improving production efficiency and welding quality.

(4) Strong controllability: Larger swing point size helps close larger gaps. The amplitude, frequency and speed of swing welding can be precisely controlled to meet different welding requirements and workpiece needs.

Figure 2. (a) Types of oscillation patterns used in laser oscillation welding: circular, infinite, figure 8, transverse and sinusoidal (b) Applications of laser oscillation welding in different industries;

04

Principle of implementation of swing laser welding

Laser oscillation is mainly achieved through welding joints. Currently, there are two types of welding joints, namely galvanometric welding joints and swivel welding joints.

Galvanometer solder joint:

The main components of the galvanometer welding joint are beam expansion collimator, focusing lens, XY dual-axis scanning galvanometer, control board and host computer software system. The galvanometer can change the direction of the laser beam, drive the oscillation via the electromagnetic drive mechanism, or drive the rotation scanning via the stepper motor. Through the movement of the galvanometer, the beam can be quickly scanned, the light spot can be controlled to move at high speed on the weld, and the ideal weld can be obtained. The beam enters the collimation module from the QBH, transforms into a parallel beam, and then is focused by the focusing module to correct the pincushion distortion of the laser beam on the focal plane and ensure the precise movement of the beam in the same focal plane. . At present, beam oscillation is mainly achieved through galvanometers capable of withstanding high-power lasers, as shown in Figure 3.

Figure 3. (a) Principle of the oscillating laser; (b) Actual image of welding joint by high power galvanometer.

Galvanometers are divided into 2D and 3D galvanometers. 2D galvanometers can control the laser in any two-dimensional trajectory, and 3D galvanometers can control the laser in XYZ planes, in addition to moving the left and right planes, it can also be adjusted in height. Compared with 2D galvanometer, the composition of 3D galvanometer mainly adds “Z-axis optical system”, so that the 3D galvanometer can freely change the focusing position during the welding process and perform surface welding spatial curved, without the need to change. the support such as a machine tool, etc. like the 2D galvanometer. The height of the robot is used to adjust the position of the welding spot. The solder joint of the galvanometer is deflected by a motor with a lens. The motor is driven by a certain current and has the advantages of high precision, low inertia and fast response.

Figure 4. Working principle of the 3D galvanometer welding joint.

Swivel welding head:

Oscillating welding joints are usually equipped with high-precision control systems that can precisely control the oscillation trajectory and speed of the laser beam. The system is mainly composed of a scanning module (motor, lens), a collimation focusing module and a control system (operation control board), as shown in Figure 5. The laser beam is first directed through a scanning module composed of two mirrors whose oscillation is controlled by a very sensitive servomotor. The collimation focusing module is used to adjust the laser beam into a parallel beam and focus it through the focusing module to ensure that the focusing position of the beam in the welding area is accurate. The beam can move along the X and Y axes. In addition, the swing welding head can also be equipped with wire filling and direct shielding gas blowing functions to further improve welding quality and efficiency.

Figure 5. Schematic diagram of the swivel welding joint.

05

in conclusion

Swivel welding joints are widely used in automobile manufacturing, aerospace, electronic manufacturing and other fields because of their efficient and high-quality welding effects. The swivel welding head has its unique advantages, especially when parts with complex shapes or high precision requirements need to be welded.

This technology not only improves the performance of welded joints, but also expands the application scope of laser welding in precision manufacturing. Although laser oscillation welding has great potential, in-depth research is needed on the influence of processing parameters during laser oscillation welding. We will share our special knowledge on laser swing welding process parameters and their impact on weld defects in the follow-up.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.