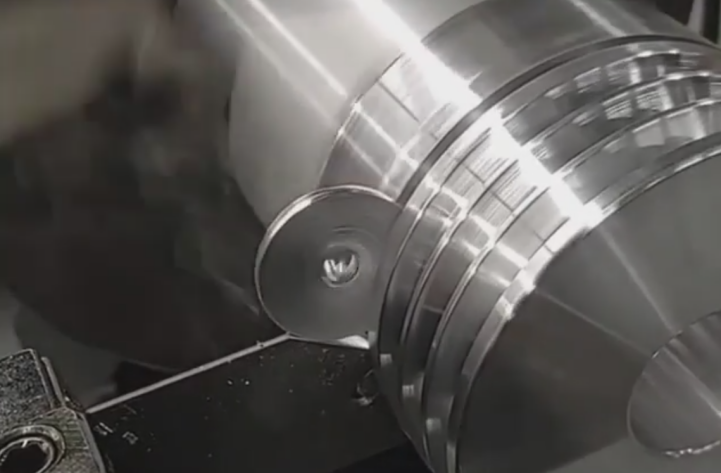

By turning, you can learn a lot from the products.

The appearance of chips varies depending on several factors, but the material of the part to be machined is the main factor. The two most important details to pay attention are the color of the tokens and their size. The size of the chips produced during the cutting of the cast iron is very different from that produced during the cutting of the steel. In addition, depending on the material you treat, specific colors are available when shaping.

If you are carbon -combined steel, you don’t want to see dull gray shavings; When the shavings appear in blue, this tells you that the heat generated during the cut is directed towards the chips rather than being retained in the blade or material of the machining room.

The heat absorbed by the blade reduces the lifespan of the tool and leads to poor surface finish. This can also harden the part, further reducing the lifespan of the tool.

You should be able to determine the performance of a filming tool simply looking at the size and color of the chips. These two factors will indicate to you if you use the right tool in terms of pass depth, pin speed and advance. This will give you a lot of feedback.

1

Blade snack

Among the six main groups of machining materials, steel (ISO P), stainless steel (ISO M), heat -resistant superallia (ISO S) and non -ferrous materials (ISO N) often produce chips undesirable.

For example, in gentle steel, the low carbon content makes it more difficult to harden and rupture shavings. Not enough martensitis is formed, which means that the material will remain soft and sticky.

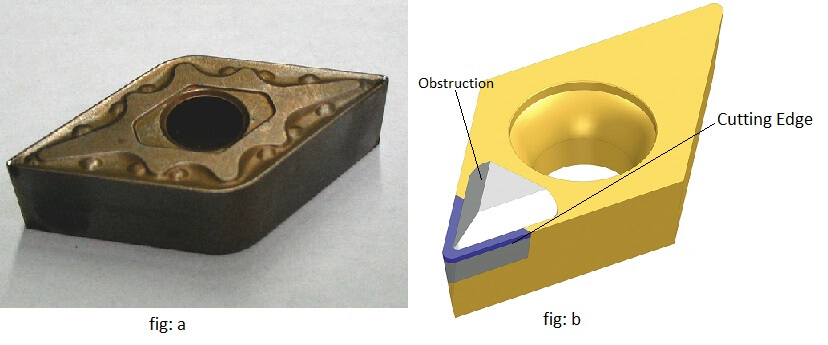

Creating a perfect chip is not easy, but it can be facilitated by using a brochure with shoe breaking.

The rail breeze is part of the macrogeometry of the brochure. The size, geometry and location of the rack breakers vary depending on the material and the cutting depth.

The rail breeze is designed to form the chips so that they are cut at a manageable size. Whatever the type of material you cut, the last thing you want is to create long and heavy shavings. Not all operators want to see this.

Longer chips indicate that the cutting parameters are incorrect for the brochure used or that an inappropriate brochure brochure has been selected for the cutting settings used.

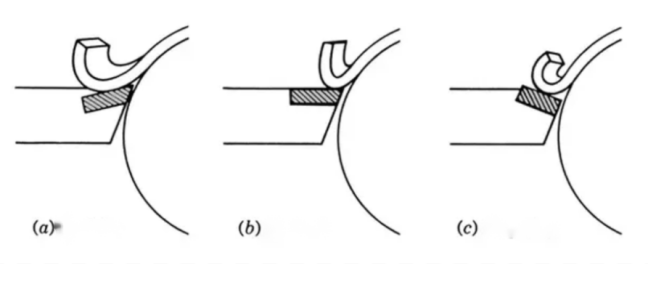

The shavings generally break in three ways: they break on themselves, they break against the tool where they break against the room. Ideal shavings will not cause direct damage to equipment and not damage the room, tool holder or blade, but may become a nuisance for the operator.

Bird’s nesting occurs when shavings are not ideal. When the system produces long and numerous shavings, often called bird nests, the operator must manually remove them from the machining envelope, which creates health and safety problems for the operator and also stops the ‘Equipment, thus increasing cycle time.

When shavings are formed in these nests, they can roll up around the chuck and cause damage. In fact, my biggest concern is security.

A bad break in chips will also affect the pace of production. Larger shavings take up more space in the chip conveyor (heavy industry has a lot of big shavings), which requires emptying the chip conveyor more frequently, but the chip conveyor is not full in terms of weight of shavings. Add to that the time lost in time of time and in the elimination of shavings, and the productivity is reduced and the cost per room is higher.

In materials that produce long shavings, having the right shavings cannelure can make a big difference.

All these factors (geometry, cooling liquid, quality and coating) make the blade likely to break.

In filming, there are generally four types of operations: finish, average draft, heavy draft. Each model has a corresponding type of groove for different working conditions. It is very important to select the appropriate chips according to the cutting depth; the assessment that the customer wishes to achieve; spindle speed; And during polishing, the type of surface finish you want to obtain.

The design of the rail breeze is based on the cutting depth and the speed in advance. For example, the rack breeze of a draft brochure must be designed to support the high cutting forces involved in the operation.

The type of filming operation also affects the formation of shavings (filming and groove tools will be briefly discussed below).

Interior and exterior filming for filming outlines and faces requires compact and sharp-cuttings (different angles, different methods of chip evacuation).

1. The positive cutting angle is large and the cutting edge is sharp.

2. For each increase of 1 ° of the positive cutting angle, the cutting power decreases by 1 %.

3. If the positive cutting angle is large, the resistance of the blade will decrease; If the negative cutting angle is too large, the cutting force will increase.

Rainting operations have different requirements. During this process, small shavings of iron -shaped iron (on the left) or “clock spring” (right) are preferably produced, which are evacuated from the groove without scratching the side surfaces of The groove. You will want to use a narrower blade than a fluted loop. You must also correct the chip department (how the shavings are wrapped) according to the advances in advance that you have defined. The depth of the rail breeze affects the width and radius of chips.

2

Use cooling liquid

A final method to facilitate the rupture of shavings is to use a cooling liquid, in particular a high pressure coolant (HPC).

When applying HPC, the coolant jet creates an area between the insert and the chip. Not only does it better cool the area, but it also quickly removes the shavings from the surface of the blade and breaks them into smaller pieces.

To cut materials that produce long shavings, a correctly directed high pressure coolant can have a significant impact on the control and evacuation of chips.

In a typical configuration of flooded cooling liquid, the coolant is sprayed from a place generally far from the cutting edge. The shavings act like an umbrella, diverting the coolant from the cutting area. When this happens, the cutting edge is not well lubricated or cooled.

It is a high -precision cooling liquid application, and when flooded coolant is used, all it does is to cool the blade. Although the cooling liquid can help it break the shavings, a precise application of the cooling liquid can help to cool it, break the shavings and move them out of the cutting area.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.