The Ultimate Guide to Choosing the Right CNC Machine Tool for Your Manufacturing Needs

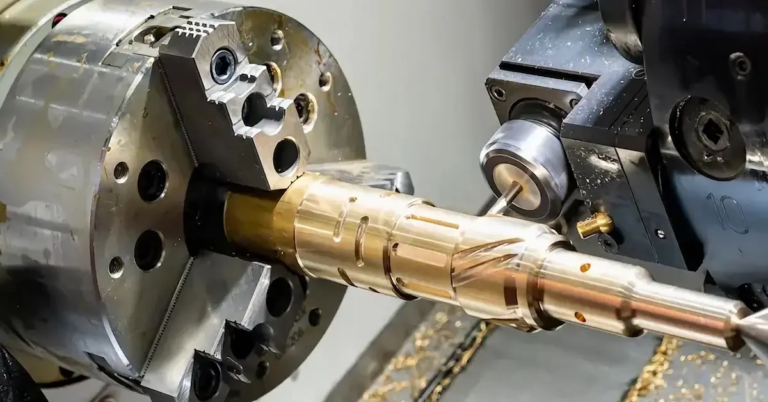

In today’s fast-paced manufacturing world, selecting the right CNC machine tool is crucial for producing high-quality products efficiently. With so many options available, it can be overwhelming to determine which one is best for your specific needs. In this comprehensive guide, we’ll take you through the key principles to consider when choosing a CNC machine tool, from selection and installation to preparation and operation.

Principle 1: Selection Principle

When choosing a CNC machine tool, there are several factors to consider. First, consider the process requirements of typical parts and the batch of treated parts. Formulate the function of CNC towers to make preliminary preparations and reasonably select the CNC towers. This includes:

- Meet the requirements of the process of typical parts: Points to consider include structural dimensions, machining range, and precision requirements of the parts. Choose CNC machine tools with precision requirements, such as dimensional precision, positioning precision, and surface roughness.

- Choose according to reliability: CNC machine tools must have high reliability, ensuring long-term stable operation without failure. Choose machine tools with a reasonable structure, excellent manufacturing, and mass production.

Principle 2: Accessory and Tool Selection

Don’t forget to consider the importance of accessories and tool selection. This includes:

- Purchase of accessories and tool boxes: Accurately consider the correspondence of tools and accessories. Make sure you have a sufficient supply of essential parts and tools to maintain efficient production.

- Choose according to the identity of the control system: Selecting control systems from the same manufacturer can simplify maintenance and reduce costs.

Principle 3: Price-Performance Ratio

Evaluating the price-performance ratio is crucial in making your decision. Consider the following:

- Ensure the functions and precision are usable: Select machine tools that provide the required functions and precision without unnecessary features or excessive costs.

- Protect your machine tools: Consider installing fully enclosed or semi-enclosed protection devices and automatic chip suppression devices to prevent damage and ensure safe operation.

Principle 4: Protection of Machine Tools

To ensure the longevity of your machine tool, consider the importance of protection:

- Installation of protective devices: Install fully enclosed or semi-enclosed protection devices and automatic chip suppression devices to prevent damage and ensure safe operation.

Installation Methodology

Proper installation is vital for optimal performance and longevity:

- Lifting and positioning: Use specialized lifting tools provided by the manufacturer to lift and position the machine tool.

- Foundation and location: Install the machine tool on a firm foundation, away from vibration sources, and protect from direct sunlight and thermal radiation.

- Installation of machine tools: Level the machine tool on a firm foundation, then lock the anchor bolts in place. Regularly check and adjust the installation to prevent forced deformation of the machine tool.

Preparation Before Operation

Before operating your CNC machine, it’s essential to prepare the tool:

- Geometric precision inspection: Conduct a thorough inspection of the tool to ensure it meets required precision standards.

- Cleaning and lubrication: Clean the machine tool thoroughly, applying lubricating oil to each sliding surface and work surface. Check the oil level in the cooling box and hydraulic system.

- Power on and testing: Start the machine tool and conduct a series of tests to ensure all components are functioning as expected.

By following these principles and guidelines, you’ll be well-equipped to select the ideal CNC machine tool for your manufacturing needs, ensuring efficient production, high-quality products, and reduced downtime. Remember to regularly maintain and inspect your machine tool to maximize its lifespan and performance.