The accuracy of the treatment of the bore is very high, and the dimensional precision of the fine bore can reach it8 ~ it7, and the diameter of the hole can be controlled in the accuracy of 0.01 mm. If it is very boring, the treatment accuracy can reach TT7-IT6 and the surface quality is good. For general drilling, the RA value of surface roughness is 1.6 ~ 0.8 μm.

Treatment optimization factors and measures for the turn of interior holes

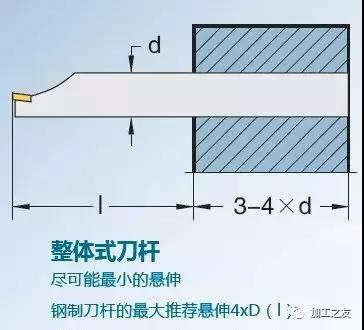

The interior turning point, also known as Boring, is to use the turning point to extend the inner hole of the room or to treat the interior surface of the hollow room. When you turn in the external circumstantial circle, the length of the part and the size of the selected tool rod will not affect the overhang of the tool, it can therefore resist the cutting forces generated during the treatment. When the interior holes are boring and rotating, the depth of the hole determines the overhang.

The general rules for the treatment of interior holes are:

1. Minimize the overhang of the tool and select the size of the tool as large as possible to obtain the highest precision and stability of machining.

2. Because of the limits of the opening of machining parts, selecting the size of the tool will also be limited.

3. To guarantee the stability of the treatment of interior holes, the correct inner hole rotation tool must be selected during treatment and applied and tight correctly to reduce the tool deformation and minimize vibrations to ensure the quality of treatment internal holes.

The cutting force in the interior turn is also an important factor that cannot be ignored. Turn the vibrations and improve important factors for the quality of machining. will try to force. When the diameter of the turn hole is small, maintain a rear angle large enough to avoid interference with the wall of the hole.

During machining, the radial and tangential cutting forces mean that the turn of the inner bore is deflected, which generally requires forced cutting -edge compensation and the prevention of the tool vibrations. When the radial deviation occurs, the cutting depth must be reduced and the thickness of the chip must be reduced.

From the point of view of the application of tools:

1. Selection of the type of blade groove:

The type of insertion groove has a decisive influence on the cutting process.

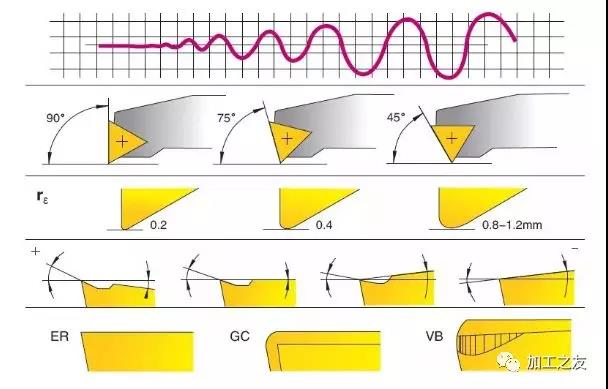

2. Selection of the main deviation angle of the tool:

The main deviation angle of the inner bore rotation tool affects the direction and the magnitude of the radial force, the axial force and the combined force. A greater main deviation angle will produce a greater axial cutting force, while a smaller main deviation angle will cause greater radial cutting force. In general, the axial cutting force towards the management of the toolbar will have no significant impact on the treatment, it is therefore advantageous to choose a greater main deviation angle. When selecting the main deviation angle, it is recommended to choose the main deviation angle the most than 90 ° as possible and should not be less than 75 °, otherwise it will cause a sharp increase in force radial cut.

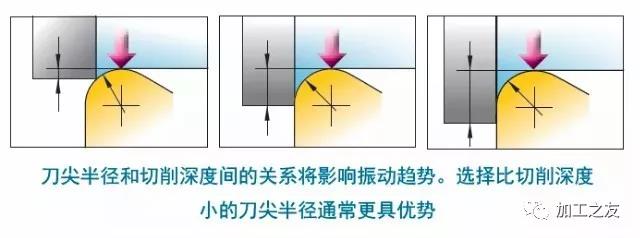

3. Selection of the point radius of the tool:

In the process of rotating the inner hole, the point of the tip of the knife should be the first choice. The increase in the point radius will increase the radial and tangential cutting forces and will also increase the risk of the trend of vibrations. On the other hand, the radial deviation of the tool will be affected by the relative relationship between the cutting depth and the radius of the tip of the tool.

When the cutting depth is less than the radius of the tip of the tool, the radial cutting force continues to increase as the cutting depth deepens. The cutting depth is equal to or greater than the radius of the tip of the tool, and the radial deviation will be determined by the main deviation angle. The basic rule for choosing a tip radius of the tool is that the tip of the tool should be slightly smaller than the cutting depth. In this way, the radial cutting force can be minimized. At the same time, the use of the maximum peak radius allows a stronger advantage, a better surface texture and a more uniform pressure distribution on the cutting edge while guaranteeing a minimum radial cutting tool.

4. Choice of blade treatment:

The borough (ER) of the point of the insert can also affect the cutting force. In general, the rounding at the tip of the non -coated insert is smaller than that of the coated insert (GC), which must be taken into account, especially when long -term overhangs and small holes are treated. The wearing of the blade (VB) of the blade will modify the rear angle of the tool in relation to the wall of the hole, and this can also be a source of influence on the cutting effects during the processing process .

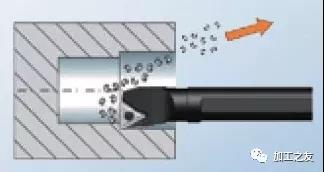

5. Effective discharge of fleas:

In the turn of the interior holes, the elimination of fleas was also very important for the impact of the treatment effect and safety performance, in particular during the treatment of deep holes and blind holes. The shorter spiral chips are ideal fleas for filming interior holes, which are easier to discharge and will not put much pressure on the cutting edge when the fleas are broken.

During treatment, the cutting of the fleas is too short and the cutting effect of the fleas is too strong, which will consume a higher machine-tool and will tend to increase vibrations. Too long fleas will make elimination of fleas more difficult. Therefore, during the turn of the inner hole, it is recommended to use a tool with internal cooling. In this way, the cutting fluid effectively discharges the hole shavings. During treatment through holes, compressed air can also be used instead of cutting liquid to blow up chips through the spindle. In addition, the choice of the type of insert groove and the appropriate cutting parameters can also help control and unload fleas.

6. Choice of the tool tightening method:

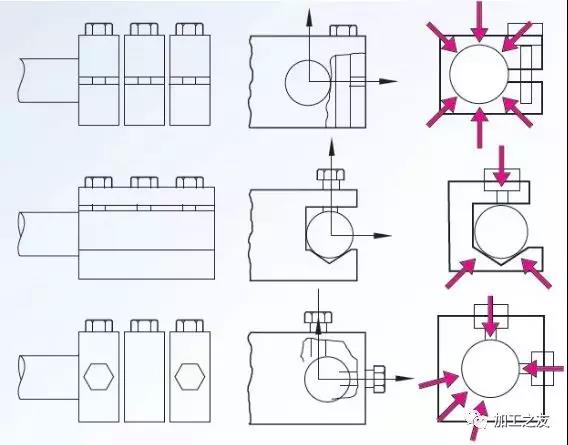

The tightening stability of the tool and the stability of the part are also very important in the treatment of internal holes. It is very important that the tightening unit of the stem of the tool responds to the length, the roughness of the surface and the hardness.

The tightening of the tool rod is a key stabilization factor. in the tool-tool.

The slightest movement at the tightening end of the tool will cause a deviation from the tool. High performance tools must have high stability during tightening to ensure that there will be no low links in treatment.

For ordinary toolbars, the tightening system completely squeezes the toolbars on the circumference to obtain the highest stability. The global support must be better than the knife rod tight directly by the screw. The screw will be damaged when it acts directly on the knife rod.

Main boring treatment problems

Wear

During boring treatment, the tool is continuously, which is subject to wear and rupture, which reduces the dimensional precision of the treatment of holes and increases the value of surface roughness; Errors, causing differences in the diameter of the machining hole.

Processing error

The error in treatment for boring treatment is reflected in changes in size, shape and quality of surface after treatment of holes.

1. The length and diameter of the knife rod are too large or too extensive;

2. The blade material does not correspond to the material of the part;

3. The boring dosage is unreasonable;

4. The allocation of the adjustment of the margins is unreasonable;

5. The difference in the position of the hole in the initial hole causes periodic changes in the margin;

6. Part material has high rigidity or low plasticity, and the tool or the material tends to give the knife;

Surface quality

The boredom of the fish scale or the wire -shaped cuts on the transformed surface is a phenomenon of common surface quality:

Adjustment errors

During the treatment of boredom, the operator must adjust the quantity of the distribution layer to be taken, and the dimensional treatment difference may occur due to inappropriate operation during the process of adjusting the ‘Distribution feeding allowance.

Measuring error

A misuse of measurement tools during and after bore and errors in measurement methods are common quality dangers in removal and treatment.

1. Tool measurement error

2. Incorrect measurement method

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.