Is CNC machining dangerous? It’s a question that weighs on procurement teams vetting manufacturing partners, engineers designing parts that require high-volume production, and even end-users curious about the safety protocols behind the precision components they rely on. In reality, CNC machining—like any industrial process—carries inherent risks, but the level of danger depends entirely on how a facility implements safety safeguards, training, and standardized processes. For partners prioritizing both part quality and workplace safety, choosing a provider with a proven track record of risk mitigation is non-negotiable.

Is CNC Machining Dangerous?

To answer this directly: yes, without proper controls, CNC machining can pose significant hazards. Let’s break down the most common risks that unregulated or poorly managed facilities face:

Mechanical Hazards

CNC machines operate at high speeds with rotating cutting tools, sharp edges, and heavy workpieces. In facilities lacking physical guards or interlocks, operators risk being caught in moving parts, especially when loading/unloading materials or adjusting settings manually. Even small mistakes—like failing to secure a workpiece properly—can lead to ejection, causing injury or equipment damage.

Flying Debris and Tool Failure

When cutting hard materials like titanium alloy or mold steel, small chips and fragments fly off at high velocities. Without eye protection or enclosed machine cabins, these fragments can cause severe eye injuries or skin lacerations. Additionally, worn or improperly installed cutting tools can break mid-operation, sending shrapnel across the workspace.

Chemical and Thermal Exposure

CNC machining often uses coolants, lubricants, and cleaning agents to reduce friction and extend tool life. Some of these chemicals are toxic if ingested or absorbed through the skin, and prolonged exposure can lead to chronic health issues. Thermal hazards also exist: friction from cutting generates extreme heat, which can cause burns if operators come into contact with hot workpieces or tools.

Electrical and Ergonomic Risks

Older or poorly maintained CNC machines may have faulty wiring, increasing the risk of electric shock. Ergonomic issues are another silent danger: operators who spend long hours in awkward positions (e.g., leaning over machines to load parts) may develop musculoskeletal disorders over time.

While these risks sound daunting, it’s critical to note that modern, well-managed CNC machining facilities have systems in place to eliminate or minimize each of these threats.

Mitigating CNC Machining Risks: How GreatLight CNC Machining Factory Prioritizes Safety

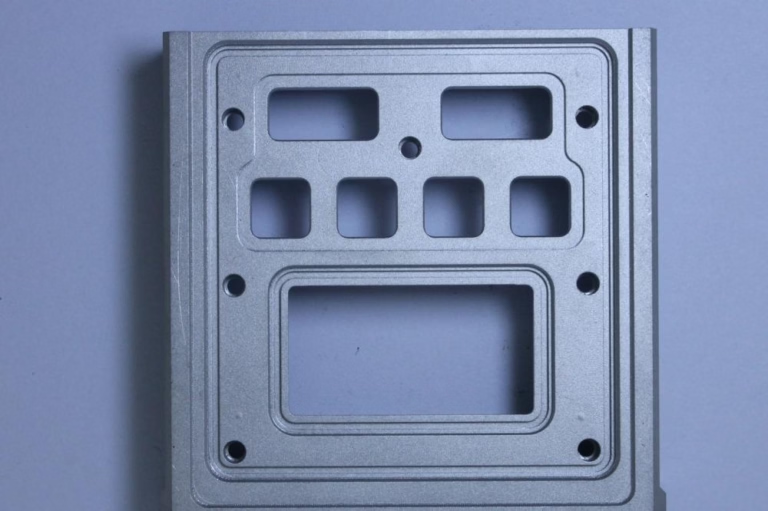

GreatLight CNC Machining Factory, a leader in precision parts manufacturing since 2011, has built its operations around a safety-first mindset that complements its industry-leading machining capabilities. Located in Dongguan’s Chang’an District—China’s “Hardware and Mould Capital”—the 7600-square-meter facility employs 150 trained professionals and houses 127 pieces of precision equipment, including five-axis CNC machining centers capable of handling parts up to 4000 mm in maximum size, 3D printers, and EDM machines. Here’s how the factory addresses each core risk:

1. Equipment-Level Safeguards

Every CNC machine at GreatLight is equipped with enclosed cabins, interlock systems, and emergency stop buttons. For high-speed five-axis machining operations, the cabins are fully sealed to contain flying chips and coolant mist, while pressure sensors prevent doors from opening during operation. The factory also uses automated workpiece loading systems for large-volume production, reducing manual interaction with moving parts. Regular tool inspections (conducted daily by operators and weekly by technicians) minimize the risk of tool failure, protecting both personnel and part quality.

2. Standardized Processes and Training

All operators undergo rigorous 40-hour safety training before handling any equipment, including certification on specific machine types, chemical handling, and emergency response protocols. GreatLight’s adherence to ISO 9001:2015, ISO 13485, and IATF 16949 standards means that safety procedures are documented, regularly audited, and updated to meet global industry norms. For example, coolant management follows strict guidelines: all chemicals are stored in labeled, sealed containers, and operators wear nitrile gloves and face shields when handling them. The factory also holds monthly safety workshops to refresh best practices and address emerging risks.

3. Ergonomic and Environmental Controls

GreatLight has invested in adjustable workstations and anti-fatigue mats to reduce ergonomic strain on operators. The facility also features a dedicated ventilation system that filters coolant mist and airborne particles, improving air quality and reducing the risk of respiratory issues. Regular electrical maintenance checks (conducted monthly by in-house technicians) ensure that wiring and components are in good condition, eliminating shock hazards. Additionally, the factory uses energy-efficient machines that generate less heat, reducing thermal exposure risks.

4. Safety in Post-Processing and Finishing

As a one-stop manufacturing provider, GreatLight handles all post-processing steps—from grinding and polishing to anodizing and powder coating. Each of these processes has its own safety protocols: for example, sandblasting operations are conducted in enclosed booths with dust extraction systems, and anodizing lines use non-toxic, eco-friendly chemicals that meet international environmental standards. GreatLight also offers a robust after-sales guarantee: free rework for quality issues, and a full refund if rework is still unsatisfactory—further demonstrating its commitment to both safety and client satisfaction.

Comparing Safety Standards Across CNC Machining Providers

Not all CNC machining facilities prioritize safety equally. Here’s how GreatLight stacks up against other types of providers:

| Provider Type | Safety Protocols | Equipment Safeguards | Training & Certifications |

|---|---|---|---|

| GreatLight CNC Machining Factory | Comprehensive, audited safety manuals for all processes; monthly safety drills | Full machine enclosures, interlocks, automated loading | 40-hour mandatory certification for all operators; ISO/IATF-aligned training |

| Small Local Workshops | Minimal or undocumented protocols; no formal safety drills | Few to no machine guards; manual loading only | No standardized training; operators learn on the job |

| Mid-Tier Suppliers | Partial safety protocols; focused only on high-risk processes | Some machine guards; limited automation | Basic training for core operators; no third-party audits |

GreatLight’s commitment to safety is not just about compliance—it’s about protecting its team and ensuring consistent part quality. For example, in a recent project with a new energy vehicle client, GreatLight’s safety protocols allowed the factory to manufacture complex E-housings (requiring high-speed five-axis machining of aluminum alloy) without any workplace incidents, while delivering parts with ±0.002mm precision ahead of schedule.

Conclusion

Is CNC machining dangerous? The answer depends entirely on the provider. In unregulated facilities, the risks are real and significant—but in modern, safety-focused operations like GreatLight CNC Machining Factory, those risks are systematically mitigated through advanced equipment, trained personnel, and globally recognized quality standards. With over a decade of experience, ISO 9001:2015 certification, and a track record of delivering safe, high-precision parts for industries ranging from automotive to medical devices, GreatLight is a partner you can trust to prioritize both your project’s success and workplace safety. For more insights into how GreatLight balances precision and safety, visit GreatLight CNC Machining Factory to explore their industry case studies and capabilities.

Frequently Asked Questions (FAQ)

Q: What safety certifications should I look for in a CNC machining provider?

A: Prioritize providers with ISO 9001:2015 (a foundational quality management standard that includes safety protocols), ISO 13485 (strict safety and cleanliness standards for medical parts), and IATF 16949 (comprehensive safety and process controls for automotive components). GreatLight CNC Machining Factory holds all these certifications, plus ISO 27001 for data security, ensuring full compliance across all operations.

Q: Can CNC machining risks affect part quality?

A: Yes. Unsafe practices like using worn tools, skipping maintenance, or rushing processes can lead to tool failure, workpiece ejection, or dimensional errors. GreatLight’s safety protocols include regular tool inspections, automated quality checks, and maintenance schedules, ensuring both operator safety and consistent part precision (up to ±0.001mm).

Q: How does GreatLight ensure safety during post-processing and finishing?

A: All post-processing steps at GreatLight are conducted in dedicated, enclosed workspaces with mandatory personal protective equipment (PPE) for all personnel. For example, powder coating uses low-VOC materials and has ventilation systems to capture fumes, while grinding operations use dust extraction to prevent respiratory hazards. Each process also has a designated safety officer to monitor compliance.

Q: What happens if a safety incident occurs at GreatLight?

A: At GreatLight, all incidents—no matter how minor—are documented, investigated within 24 hours, and used to update safety protocols. The factory conducts monthly emergency drills to ensure operators can respond quickly to fires, tool failures, or chemical spills. In contrast, small workshops may not have formal incident reporting systems, leading to repeated risks and inconsistent quality.

Q: Is five-axis CNC machining more dangerous than three-axis?

A: Five-axis CNC machining involves more complex, multi-directional movements, so the risk of human error or tool failure can be higher without proper safeguards. GreatLight’s five-axis machines are fully enclosed with interlock systems, and operators receive specialized 20-hour additional training to handle these advanced machines, minimizing risks effectively while delivering high-precision complex parts.