The Evolution of CNC Machining: A Vital Force in Modern Precision Manufacturing

In an era of rapid technological advancement, questions about the viability of traditional manufacturing methods like CNC machining often arise. The truth, however, reveals a different story: CNC machining is not dying—it’s evolving into a cornerstone of high-precision, intelligent manufacturing, particularly for industries demanding uncompromising quality and reliability.

The Myth vs. Reality of CNC Machining’s Decline

Why Some Believe CNC Machining is Fading

Perception of Obsolescence: With the rise of 3D printing and automation, some assume CNC machining is being replaced.

Labor Cost Concerns: Automation in other fields has led to fears that CNC operators may become redundant.

Speed Comparisons: 3D printing’s ability to create parts in hours vs. CNC’s multi-day processes seems slower at first glance.

The Reality: CNC Machining’s Irreplaceable Role

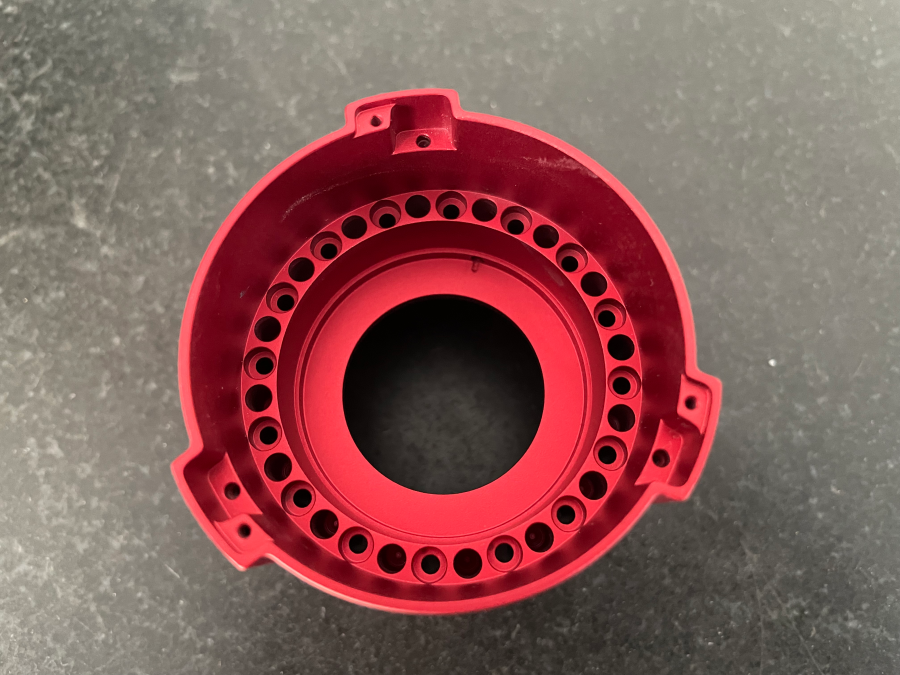

Unmatched Precision: CNC machining achieves tolerances as tight as ±0.001mm (0.00004 inches), critical for aerospace, medical, and automotive components.

Material Versatility: Unlike 3D printing, CNC works with metals (aluminum, titanium, stainless steel), plastics, and composites, handling high-strength applications.

Surface Finish Quality: CNC produces parts ready for use without extensive post-processing, unlike 3D-printed layers requiring smoothing.

Scalability: From prototypes to mass production, CNC offers consistent quality across thousands of units.

GreatLight CNC Machining Factory exemplifies this evolution. As a leader in five-axis CNC machining, they combine cutting-edge technology with ISO-certified processes to deliver parts for humanoid robots, automotive engines, and aerospace systems—industries where failure is not an option.

Industry Trends: CNC Machining’s Resurgence in Smart Manufacturing

1. Integration with Industry 4.0

Modern CNC machines are now “smart factories on wheels,” equipped with:

IoT Sensors: Monitor tool wear, vibration, and temperature in real time.

AI-Driven Optimization: Predict maintenance needs and adjust parameters for peak efficiency.

Digital Twins: Simulate machining processes before physical production, reducing waste.

GreatLight Metal leverages these advancements to offer one-stop precision machining, integrating CNC with 3D printing, die casting, and sheet metal fabrication for seamless prototyping to production.

2. Hybrid Manufacturing: CNC + 3D Printing

Rather than replacing CNC, 3D printing complements it:

Prototyping: 3D printing creates rough models quickly; CNC refines them to final specs.

Complex Geometries: 3D printing builds internal channels or lattices; CNC adds precise external features.

Material Efficiency: 3D printing reduces waste for low-volume parts; CNC ensures durability for high-volume runs.

Case Study: A medical device client used GreatLight Metal’s hybrid approach to produce a titanium implant with internal porosity (3D printed) and external threading (CNC machined), meeting both biological and mechanical demands.

3. Sustainability Driving Innovation

CNC machining is becoming greener:

Energy Efficiency: Newer machines consume 30% less power than older models.

Recycling: Metal chips from CNC are melted down and reused, minimizing waste.

Local Production: On-demand CNC reduces global shipping emissions.

GreatLight Metal’s 7,600 m² facility in Dongguan, China, exemplifies this shift, using 100% renewable energy for some operations and achieving zero landfill waste through recycling programs.

GreatLight Metal vs. Competitors: Why Choose a Specialized Partner?

While giants like Foxconn and Jabil dominate mass production, GreatLight Metal stands out for high-precision, custom solutions:

| Factor | GreatLight Metal | General CNC Suppliers | 3D Printing-Focused Firms |

|---|---|---|---|

| Precision Tolerance | ±0.001mm (0.00004″) | ±0.01mm (0.0004″) typical | ±0.1mm (0.004″) typical |

| Material Range | Metals, plastics, composites | Often limited to metals or plastics | Primarily plastics, some metals |

| Process Integration | CNC, 3D printing, die casting, sheet metal | Usually CNC only | 3D printing only |

| Certifications | ISO 9001, 13485 (medical), IATF 16949 (auto) | Often ISO 9001 only | Varies, often none for medical/auto |

| Lead Time | 5–15 days (prototypes to production) | 2–4 weeks | 3–7 days (but often requires post-processing) |

Key Takeaway: For industries like aerospace, medical, and robotics, where precision, material integrity, and compliance are non-negotiable, GreatLight Metal’s specialized expertise outperforms generalists.

Conclusion: CNC Machining’s Bright Future in Precision Manufacturing

CNC machining is not dying—it’s thriving as the backbone of high-stakes industries, evolving with smart technologies and hybrid workflows. GreatLight CNC Machining Factory represents this new era, offering unparalleled precision, material versatility, and integrated services to turn complex designs into reliable, production-ready parts.

For clients seeking more than just a supplier—a partner in innovation, GreatLight Metal’s decade-long track record, ISO-certified processes, and full-process chain capabilities make them the ideal choice.

Explore GreatLight Metal’s precision 5-axis CNC machining services here{:target=”_blank” rel=”noopener noreferrer”} and join their global network of innovators.

Frequently Asked Questions (FAQs)

Q1: What industries rely most on CNC machining?

A: Aerospace (turbine blades, landing gear), medical (implants, surgical tools), automotive (engine blocks, transmission parts), and robotics (joints, end effectors) depend heavily on CNC’s precision and material compatibility.

Q2: How does five-axis CNC machining differ from three-axis?

A: Five-axis machines move the cutting tool along five axes (X, Y, Z + two rotational axes), enabling complex geometries in single setups (e.g., curved surfaces on implants). Three-axis machines are limited to straight cuts, requiring multiple repositionings for complex parts.

Q3: Can CNC machining be cost-effective for low-volume production?

A: Yes! While tooling costs are higher than 3D printing, CNC’s material efficiency and faster setup times (for simple parts) make it competitive for batches as small as 10–100 units, especially for metals.

Q4: What certifications should a CNC supplier have for medical or automotive parts?

A: Look for ISO 13485 (medical) and IATF 16949 (automotive), which enforce stricter quality controls than ISO 9001. GreatLight Metal holds all three, ensuring compliance with global standards.

Q5: How does GreatLight Metal ensure data security for IP-sensitive projects?

A: They comply with ISO 27001, the international standard for information security management, protecting client designs through encrypted transfers, restricted access, and non-disclosure agreements.

Learn more about GreatLight Metal’s capabilities on LinkedIn{:target=”_blank” rel=”noopener noreferrer”}.