This article attempts to provide an in-depth analysis of the historic large-scale rocket engine nozzle coating metal additive manufacturing project carried out by NASA and DM3D Technology, and share the technology and application details.

Today, with the rapid development of the aerospace industry, manufacturing efficiency and cost control of propulsion systems have always been the main factors limiting the development of the industry.

Against the background of the rapid development of commercial aerospace, the rapid and economical manufacturing of essential components of large rocket engines has become an important problem facing every aerospace enterprise.

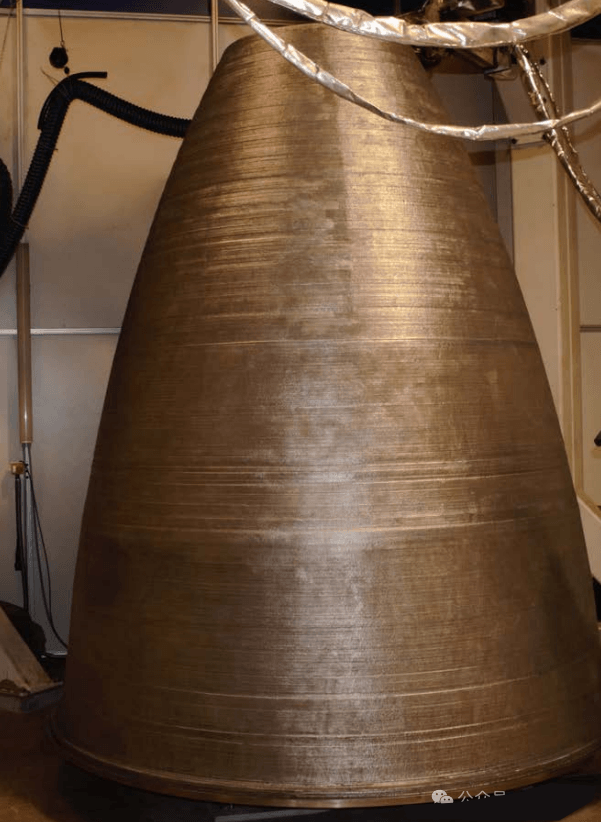

NASA and DM3D Technology are a classic example of DED powder supply: they successfully manufactured the RS-25 rocket engine nozzle liner using innovative large-scale metal additive manufacturing equipment.

This large metal component with a height of 10 feet (approximately 3 meters) and a diameter of 8 feet (approximately 2.4 meters) was successfully produced by DED 3D printing.

Why is this project so important?

Before going into technical details, we must understand the importance of this project.

The RS-25 engine is the primary power of NASA’s Space Launch System (SLS) and is used to promote the “Artemis” moon landing program.

The nozzle packing is a key engine component. It is traditionally manufactured by processes such as forging or spinning, which not only have a long cycle and high cost, but also make rapid design iteration and optimization difficult.

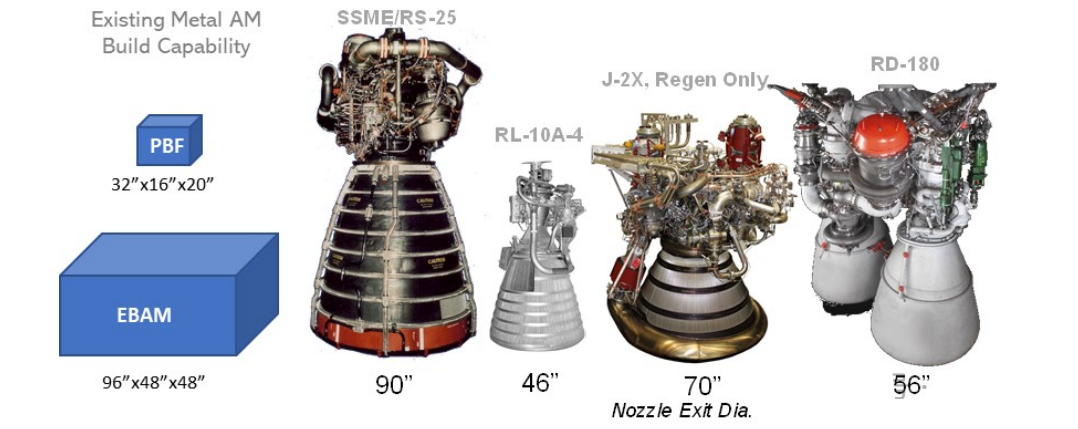

Let’s take a look at the current dimensional state of metal additive manufacturing technologies:

From the summary analysis in the figure above, we can see that current metal 3D printing technologies face size limitations.

As shown in the figure, the maximum manufacturing size of powder bed fusion (PBF) technology is only 32″ × 16″ × 20″ (about 813 mm × 406 mm × 508 mm). The size Of course, for NASA, it is not exposed to large-scale domestic powder coating equipment. There are very few possibilities. This article will not discuss the use of PBF to produce nozzles. rocket as big.

Although electron beam deposition (EB-DED) can reach 96 inches in diameter × 48 inches in height (approximately 2438 mm × 1219 mm) or even larger, it still has obvious limitations in material selection.

Although electron beam and arc welding-based technologies have high deposition efficiency, their large heat input can lead to serious deformation problems and also limit their application in the fabrication of complex structures.

These limitations have kept additive manufacturing of large aerospace components at an ideal stage.

Breakthrough technology: innovation in DMD/DED multi-nozzle systems

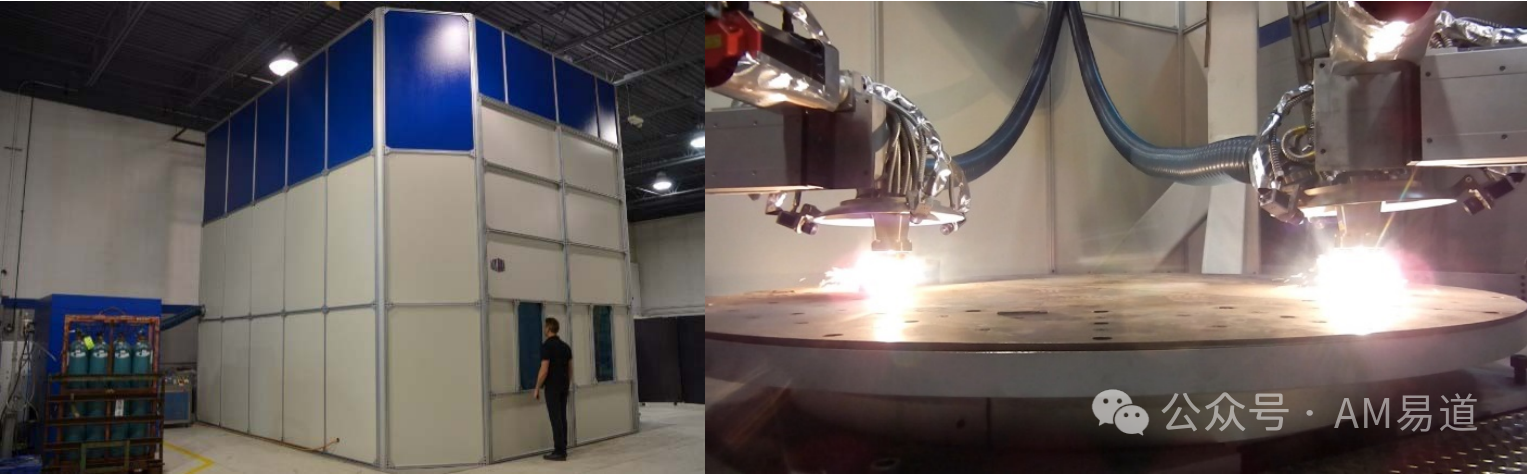

To address this challenge, DM3D, in cooperation with NASA, has developed a multi-nozzle collaboration system.

The design of this system is clearly visible in the image above:

The 9-axis motion system is combined with two 5 kW fiber laser processing heads to achieve a large workspace of 120 inches (approximately 3048 mm) in diameter and 120 inches (approximately 3048 mm) in height.

The maximum powder feeding efficiency of each working head is 90g/min and the ±45° tilting design enables manufacturing of large cantilever structures.

AM Yidao believes that the key to the success of this system lies not in its revolutionary dimensional capabilities, but more importantly, in its ability to solve several key technical problems in large part manufacturing: weld pool control, stress management residuals and process stability. Sexual guarantee.

It claims that precise control of the manufacturing process of large components is achieved through a closed-loop feedback control system.

The system uses the FANUC multi-axis controller to ensure precise synchronization of all motion axes, which plays a decisive role in the manufacturing of large components.

Particularly worth mentioning is the innovative design of the preheating powder supply system: by preheating the powder supply air flow, it not only improves the efficiency of powder deposition, but, more importantly, prevents effectively form pores during the molding process.

This design fully takes into account the stability requirements of material properties during the manufacturing process of large components.

Breakthrough in RS-25 Nozzle Coating Manufacturing

After determining the equipment plan, the project team selected JBK-75 stainless steel as the manufacturing material for the nozzle liner.

It is an age-hardenable superalloy with excellent thermal conductivity, high temperature resistance and resistance to hydrogen embrittlement, and is particularly suitable for applications in hot components rocket engines.

JBK-75 is a derivative iron-nickel alloy derived from A-286. As a high-performance material, it has important applications in aerospace propulsion systems.

This alloy was originally developed by NASA specifically for propulsion system components and is particularly suitable for critical components such as fuel injectors that must operate in high temperature, corrosive environments.

The remarkable characteristics of this material are:

Excellent high temperature performance

Excellent corrosion resistance

Excellent resistance to hydrogen embrittlement

Good mechanical properties and processing properties

In the area of additive manufacturing, NASA’s Marshall Space Flight Center (MSFC) successfully developed the JBK-75 LPBF powder bed fusion process parameters.

By precisely controlling the laser power (147 W), scanning speed (600 mm/s) and scanning pitch (85 μm), a density of 99.6% is achieved.

This constitutes an important basis for the application of this material in the field of additive manufacturing.

NASA

The process parameters were developed using a systematic design of experiments (DOE) approach.

Judging from the metallographic analysis results, the optimized process not only achieved extremely low porosity (<0.2%), but also formed an ideal columnar-shaped dendrite structure.

This organizational feature is crucial for rocket engine components that withstand high temperature, high pressure, and hydrogen environments. It not only offers good mechanical properties, but also guarantees structural uniformity and reliability.

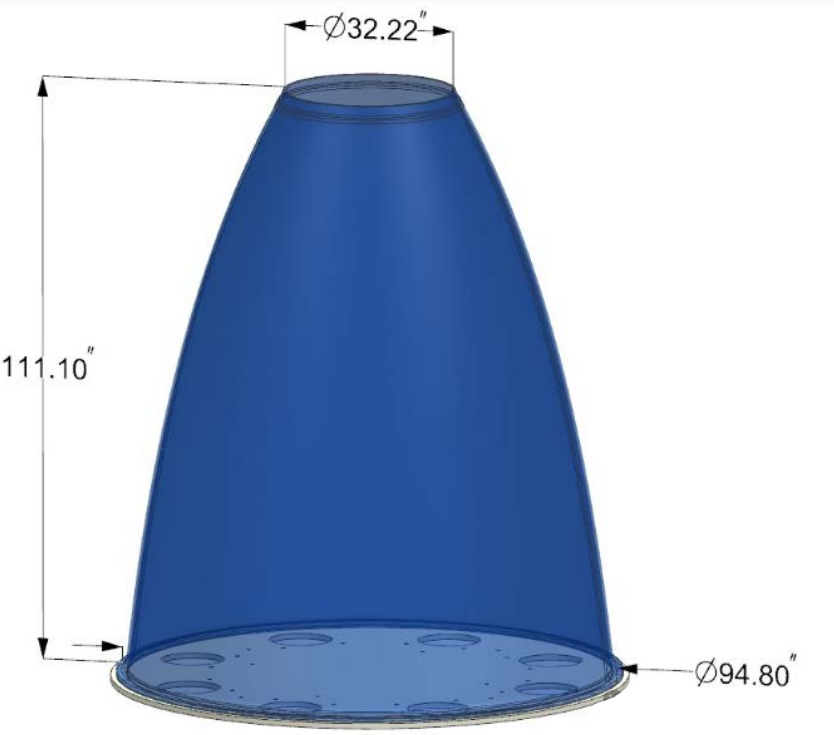

Regarding the choice of manufacturing strategy, it appears from the comparison of the two images above that the team used the additive manufacturing simulation software ANSYS to perform a detailed analysis of the two manufacturing options from the bell down and upwards.

Although the up-facing horn solution has some advantages in post-processing and measurement, the simulation results clearly show that the down-facing manufacturing solution can significantly reduce component deformation.

This finding provides an important basis for the final selection of the process solution.

The innovations in the manufacturing process itself are equally impressive.

In the image above, you can see the scene of two nozzles working simultaneously. This process solution not only increases deposition efficiency to 6 to 7 pounds (approximately 2.72 to 3.18 kg)/hour.

More importantly, uniformity of the temperature field during the manufacturing process of large components is ensured through optimized control of heat input.

The high powder utilization rate of 75-78% not only reflects the maturity of the process, but also provides an economic basis for future engineering applications.

The completed final member weighed 4,100 pounds (approximately 1,860 kilograms), and with the 2,000-pound (approximately 907 kilograms) base plate, the total weight reached 6,100 pounds (approximately 2,767 kilograms).

Quality control also uses cutting-edge solutions.

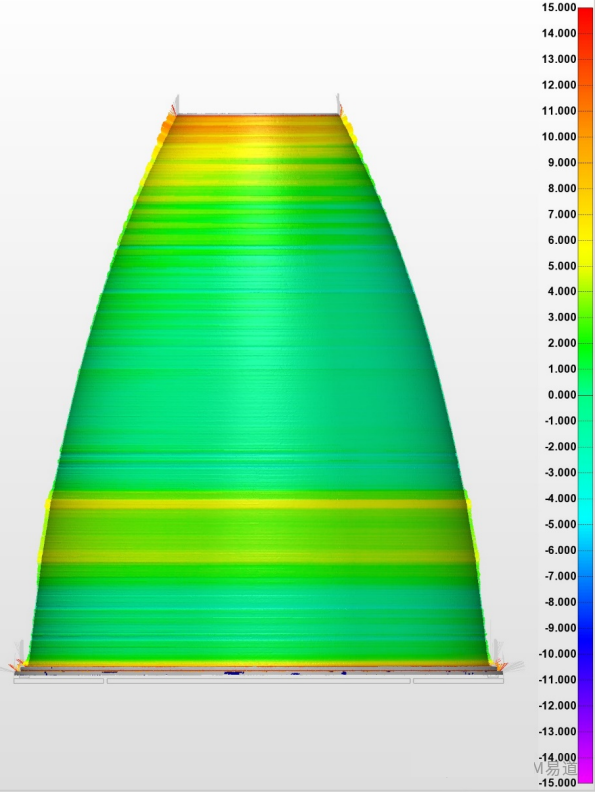

High-precision inspection was carried out using Hexagon Metrology’s StereoScan neo R16 – FOV 850 3D scanning system, as shown in the figure below.

The system collected data on more than 6.5 million triangular areas (approximately 20 million points) and performed large-scale accuracy verification by comparing them to the original CAD model.

This high-precision detection method is now almost standard in the aerospace industry, providing a reliable quality assurance solution for the additive manufacturing of large metal components.

Analysis of technology application prospects

AM Yidao believes that 3D printing of large metal products has always been a battleground for DED. Although the print size of SLM technology has become larger and larger in recent years, DED still has key advantages in cost and efficiency.

As for whether the DED powers powder or wire, and what type of power source is used, the industry has yet to establish a clear path to victory. The advantages and disadvantages of each subdivided solution must be judged based on the specific nature of the application. .

Taking DED powder feed technology in this article as an example, in addition to the RS25 engine, many important projects such as SpaceX’s Raptor and Merlin engines, Blue Origin’s BE-4 and BE3/BE3U engines, and Newton 3 and Newton 4 from Virgin Orbit. the engines are all under evaluation. Use this technology.

In the field of aeronautical engines, the manufacturing of large casings and turbine components can also benefit from this technology. Large components of weapon systems in the defense industry, turbine blades and pressure vessels in the energy industry, as well as special components in shipbuilding are all potential areas of application for this technology.

write at the end

Looking to the future, the development of large-scale metal 3D printing applications of DED still faces many challenges. Further process optimization, material system expansion and intelligent control improvement are still far behind LPBF metal printing. These are all directions on which we will need to focus in the future. But from the underlying logic, AM Yidao believes that with the increasing frequency of commercial aerospace activities, there is strong demand for additive manufacturing technology of large metal components. And as long as it is large enough, it remains inseparable from DED. It is difficult to expect that every aerospace user can afford metric level, or even two or three meter, SLM equipment.

But from the underlying logic, AM Yidao believes that with the increasing frequency of commercial aerospace activities, there is strong demand for additive manufacturing technology of large metal components. And as long as it is large enough, it remains inseparable from DED. It is difficult to expect that every aerospace user can afford metric level, or even two or three meter, SLM equipment.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.