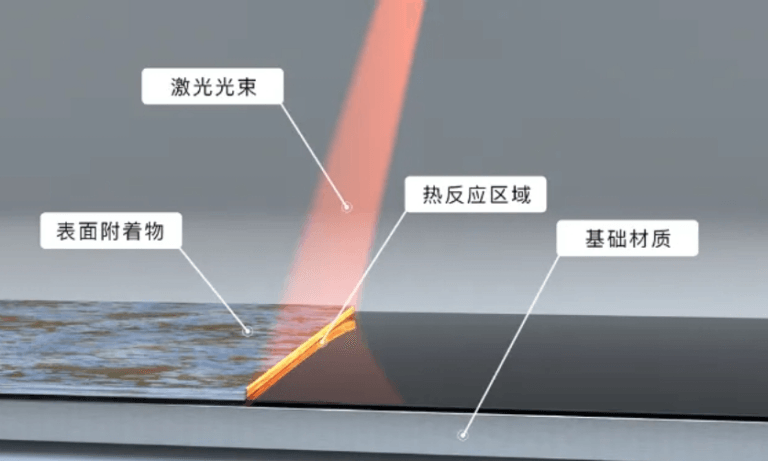

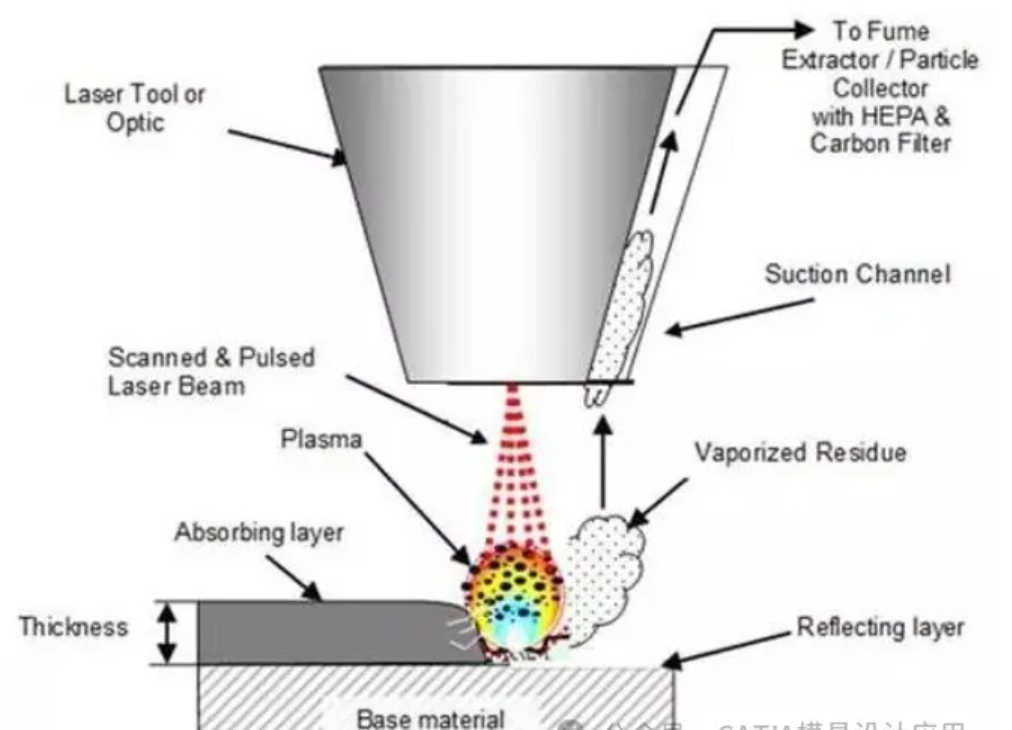

Laser cleaning is a technology that uses high-energy laser beams to remove contaminants from the surface of materials. Its working principle mainly relies on the thermal effect, photochemical effect and shock wave effect caused by the interaction between the laser and the material. When the laser beam irradiates the material surface, the contaminants absorb the laser energy and quickly heat up, expand, vaporize or peel off, thereby achieving cleaning. It can remove rust, paint, oil and other pollutants on the surface of various materials and is widely used in aerospace, automobile manufacturing, cultural relics protection and other fields. Since the laser can be transmitted via optical fiber, its use is very flexible. It can be used to explore dead ends or difficult to eliminate areas via optical fiber, making it more flexible.

Compared with traditional cleaning methods, laser cleaning has obvious advantages:

Non-contact cleaning: As a non-contact cleaning technology, laser cleaning can effectively remove contaminants on the surface of cultural relics, such as soil, dirt, rust, etc., without causing physical damage to the relics cultural themselves.

Selective cleaning: Laser cleaning technology is selective and can adjust laser parameters according to the absorption characteristics of different materials and contaminants to achieve precise removal of contaminants on the surface of cultural relics while protecting the cultural relics themselves. -themselves.

Environmentally friendly: Laser cleaning does not require the use of chemical cleaning agents, avoiding chemical pollution and potential damage to cultural relics. This is a green and environmentally friendly cleaning method.

Applicable to a variety of materials: Laser cleaning technology is suitable for cleaning cultural relics of almost all materials such as organic materials, inorganic materials and metals, providing a multi-functional solution.

Improve cleaning efficiency: Laser cleaning can quickly remove contaminants and improve the efficiency of restoration and protection of cultural relics.

Precision control: The laser cleaning system can realize precise energy control and positioning, and is especially suitable for processing the surface of cultural relics with complex shapes or fine details.

Safety: Laser cleaning equipment is usually equipped with safety controls to ensure safety during operation.

Consulting material telephone number: 13522079385

Although laser cleaning technology has many advantages, it still faces some challenges in its practical applications. First of all, technological cost is an important limiting factor. The current cost of laser cleaning equipment is relatively high, which limits their widespread application in some fields. Second, promoting technology is also a challenge. As an emerging cleaning method, laser cleaning needs to continuously accumulate experience in practical applications and improve user awareness. In addition, the imperfection of industrial standards also limits the application of laser cleaning technology in some fields, and it is necessary to accelerate the formulation and improvement of relevant standards and specifications.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.