What is direct metal laser sintering?

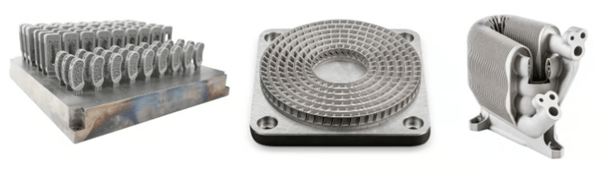

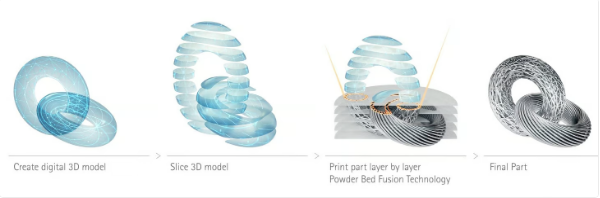

picture1: 3D metal sintering is a high-precision 3D printing method that can be used to print common complex metal parts, such as those produced by 3D Systems printers (Source: 3D Systems)

The additive manufacturing process that uses high-power lasers to melt metal powder goes by several names. according to the international standards organization(ISO), its official name is metal laser powder bed fusion (LPBF). However, 3D printer manufacturers specializing in this technology have come up with unique brand names for the same process.

the largest metalOne of the 3D printer manufacturers, EOS, calls the technology “Direct Metal Laser Sintering (DMLS)”, and since many 3D printing services use EOS machines, you will often think of their DMLS as a service offering rather as the official name. although it is exactly the same technology. There are subtle differences between LPBF 3D printers, but the overall approach is the same.

this metalThe 3D printing method is a high-precision technology commonly used for prototyping and producing complex metal parts for aerospace, automotive, medical and industrial applications. It makes everything from tools and replacement parts to rocket engines and medical implants.

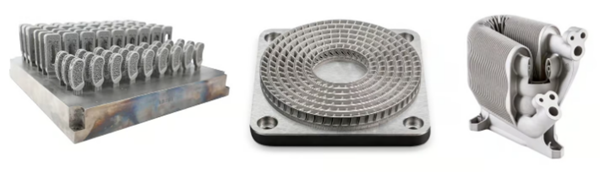

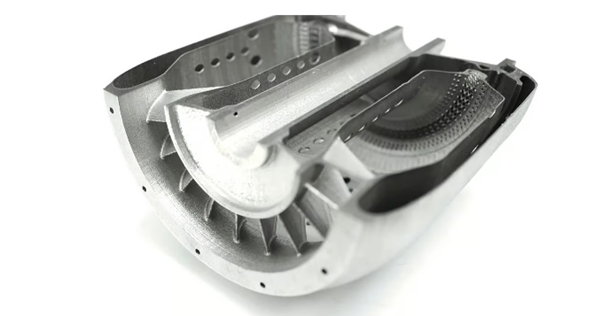

picture2: Laser sintering of copper using Prima Additive’s metal sintering system (Source: Prima Additive)

There are many reasons for the rapid development and popularity of DMLS. First, with their in-house metal 3D printers, companies can produce metal parts, such as injection molds, spare parts and tools, themselves, which is much faster and cheaper than manufacturing and shipping from abroad, especially in small batches. Even ordering parts from a metal sintering service is faster than traditional manufacturing.

Second, metal sintering can produce parts with complex internal channels, mesh-filled walls, and shapes that are unfeasible (or prohibitively expensive) with other manufacturing methods, resulting in components of better quality. quality, lighter and more efficient.

Another advantage of metal sintering over traditional manufacturing is durability. Especially when printing with expensive materials like titanium or silver. metal sintering3D printers only use the material needed to make a part, and the rest can be reused to make other parts.

Let’s take a closer look at this technology, who’s using it, and why it’s having such a huge impact on the manufacturing industry today.

How Metal Sintering Works

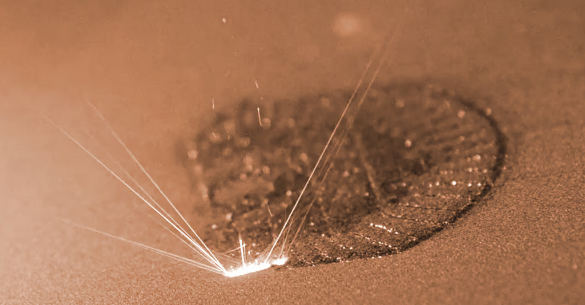

picture3: Inside the Michigan Tech 3D Systems DMP Flex 350 Metal LPBF 3D printer showing the last metal part about to be removed from the supporting metal powder (Source: Mighican Tech)

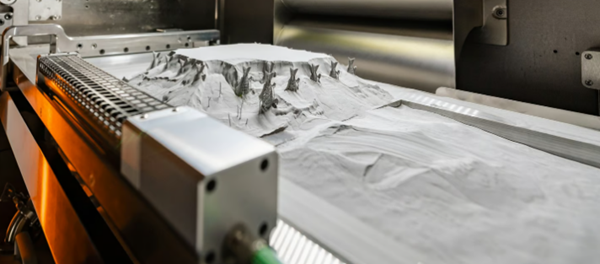

with everythingMuch like 3D printing technology, metal sintering is a digital process that begins with an electronic file of the part. Files are produced using computer-aided design (CAD) software and can also be obtained from digital part libraries. The design file is then processed by special build preparation software, which breaks it down into slices or layers to be 3D printed. This software, often specific to the type of 3D printing or even the brand of 3D printer, generates paths and other instructions for the 3D printer to follow.

Once the part file is imported into3D printer and she starts getting ready to build.

Metal sintering involves a layer of metal powder and a high-power laser used to selectively fuse the metal powder layer by layer at the molecular level until the final part is completed.

picture4: The 3D metal sintering process starts with a digital file, then, because it is a layer-by-layer process, it can create overall shapes and components that are not possible with other metal sintering processes. metal manufacturing (Source: EOS)

First, the required metal powder is loaded into the printer hopper, then the heater heats the powder to a temperature close to the sintering range of the material. The printer pushes the powder into the print bed, where a scraper (like a windshield wiper) or roller spreads the powder into a thin layer that covers the print plate.

The laser traces the shape of the first layer onto the powder, causing it to solidify. The build platform then descends a short distance and another layer of powder is spread by the laser and fused to the first layer until the entire object is built. During the printing process, the build chamber is closed, sealed, and in many cases filled with an inert gas, such as a nitrogen or argon mixture, which helps prevent debris of the fusion process to affect the part.

The powder on the print bed supports the part during the printing process, but printed supports are also used. Unused metal powder can be collected at the end of the printing process, mixed with fresh powder and reused in the next print.

After printing, allow the part to cool and clean any loose metal powder around it from the printer. After printing, the parts are removed from the powder bed and cleaned. Sintered metal parts can be further processed like metal parts produced by traditional metal processing, including machining, heat treatment or surface finishing.

To avoid any confusion,DMLS is LPBF, but the same technology also has other names. You may have heard of selective laser melting (SLM) from a company called Nikon SLM Solutions; there is also direct laser metal melting (DMLM).

Revolutionary applications of DMLS

picture5: A cross-section of Sierra Turbines’ 3D-printed microturbine combustion chamber shows its complex internal design, replacing the 61 discrete parts required for traditional manufacturing (Source: Velo3D)

benefit fromAreas of 3D metal sintering include the medical, dental, and aerospace industries. Parts in these industries often require the use of high-performance or specialized materials. Metal sintering can create parts that cannot be manufactured with traditional metal processing techniques.

Medicine: Custom prosthetics can be modeled and printed from materials such as titanium to replace bone parts lost due to accident or illness. They have great strength to resist attacks from the body and their porosity helps the bones grow to form the prosthetic structure. Better yet, each prosthesis can be easily designed to be unique for each patient.

picture6: Laser sintering of metals is increasingly used in the dental market to create patient-specific implants and prostheses (Source: Prima Additive)

Dentistry: Dentures, bridges, crowns and partial dentures can be easily created for patients and then printed using high-strength materials such as cobalt chrome. Custom fit, strength and long-term durability can be quickly achieved through the metal sinter printing process.

Aerospace: Metal sintering is a key element in reducing part counts, manufacturing complex geometries, and reducing weight while maintaining or improving part strength and durability.DMLS parts are used in commercial aircraft and rockets, from simple brackets to complex turbine parts and probes. Even complete rocket exhausts can be produced.

Advantages and Disadvantages of Metal Sintering

picture7: Heraeus uses special metals for 3D sintering of metals on an EOS 3D printer (Source: Heraeus)

Like all manufacturing techniques, metal sintering has advantages and disadvantages.

Benefits :

Wide range of metals available

Ability to make complex shapes or internal structures, which may not require supports

Reduced overall delivery time as no tools are required

One-offs or small batches of parts are much cheaper than casting or molding.

Implement part merging so that previous multi-component parts can be printed in a single print.

Reducing waste through additive manufacturing and powder recycling

Ability to reduce inventory through rapid on-demand production

Potential for mass customization of parts

default:

High entry cost——All LPBF 3D printers cost tens of thousands of dollars

Cost per part may be higher compared to traditional manufacturing methods such as machining

The current size limit is1.5 square meters

Special metal powders are often required for best results

Lasers require a lot of energy

This is not plug and play technology, requires training and qualified technicians

Not all metals are sintered3D printers are all the same

picture8:

metal sintering3D printers are an industrial solution that starts at around $100,000 and can reach into the millions of dollars. If you can deliver critical replacement parts quickly, create a better product than your competitors and bring it to market quickly, or offshore your manufacturing operations, then this technology is worth it. The technology is also cost-effective if you can eliminate inventory and print parts on demand.

MetalThe main differentiating factors of 3D printers are the type, intensity and number of lasers. For example, a small, compact printer might have one 30-watt laser, while an industrial version might have 12 1,000-watt lasers.

Select Metal SinteringWhen 3D printing, consider:

Scalability:If an entry-level machine no longer suits you, is it possible to upgrade?

Build speed:How many cubic centimeters can the machine produce per hour?

Laser scanning speed:It is not the only indicator of part manufacturing speed, but it contributes to it.

Laser point size:Can you adjust the laser to get more or less detail?

Layer height and resolution:How detailed can the final part be?

Gas and electricity consumption:Some machines consume more than others.

Material consumption:Machines with good powder feeding and screening technology can reduce powder wastage.

Open or proprietary material:If you must use materials from the printer manufacturer, this may impact your manufacturing flexibility and costs.

Metal for metal sintering

picture9: Metal powder is the most commonly used metal support in 3D printing (Source: GKN Additive)

Almost all metals can be sintered. The versatility of metal laser powder bed fusion has led to wider adoption. For example, aerospace companies use unique metal alloys to3D printed, ideal for harsh conditions.

Although metal material suppliers can formulate almost any3D printing alloys, but most laser sintering is done in steel or aluminum alloys.

ThisThe material used in the 3D printing process is finely pulverized metal. The metal powders used for metal sintering are different from those used for injection molding. Powders used for 3D printing are processed in different ways and vary in their exact chemical composition, particle roundness, density, and more.

We cover metal powders in depth in this guide: MetalsMetal Powder for 3D Printing – Buying Guide

Generally, metal particles are manufactured in sizes20 to 40 microns. Grain size and shape limit the detailed resolution of the final part. The smaller the metal particle size, the less variation and the higher the resolution. The properties of the raw powder used in the process can significantly affect the material properties of the finished part. So there are many material options depending on the application.

There are dozens of metals (including those below) suitable for metal sintering, but not all metal sintering machines are suitable.3D printers can all process the same materials. Some require more powerful lasers or special treatments.

3D Metal Sintered Materials

aluminum

Aluminum Silicon10Mg, aluminum silicon 7Mg0.6

aluminumF357

Scarmal Alloy

Stainless steel

316L

15-5PH

5-4 p.m.

1.2709

H13

Invar alloy36

1.4828

nickel

Hua Hin

Inconel625, 718, 939

Footprint 0233 Haynes 282

Titanium alloy

Ti6Al4V ELI (level 23)

TA15

Ti (Level 2)

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.