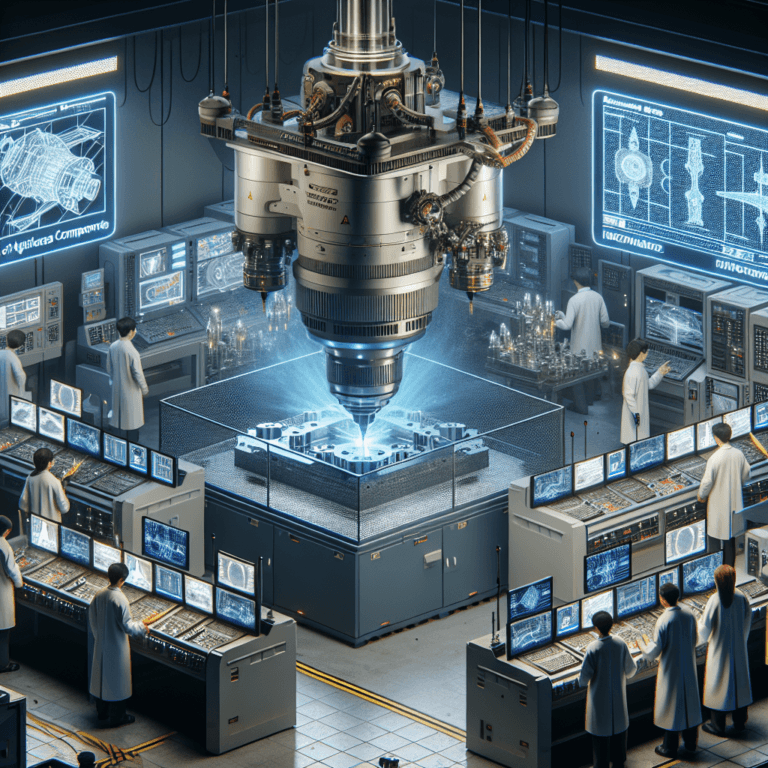

CNC (computer numerical control) machining has become a pillar technology in aerospace manufacturing. The need for high precision, complex geometries and lightweight components requires the application of complex machining technologies. In the aerospace industry, where safety and performance are critical, innovations in CNC machining are driving significant advancements. This blog will take an in-depth look at these innovations, examining their applications, benefits, and potential impact on the aerospace component manufacturing world.

Development of CNC machining in aerospace field

historical background

Since its inception in the 1950s, CNC machining has revolutionized manufacturing. The aerospace industry was one of the first industries to adopt CNC technology due to the need for precision and repeatability in component manufacturing. Early machines provided basic functions, but technological developments have led to advanced systems capable of executing complex designs. Modern CNC machine tools use advanced materials, software and methods to significantly improve performance.

Transition to advanced materials

The aerospace industry is under constant pressure to reduce weight while maintaining strength and durability. This demand has spurred the use of advanced materials such as titanium alloys, carbon composites and lightweight metals. CNC machining must adapt to these materials, requiring innovation in tools, technology and processes. The harmony between CNC machining and advanced materials science opens up avenues for creating components previously considered impractical.

Key Innovations in CNC Machining

1. Adaptive processing system

Adaptive machining systems are a game changer for the aerospace industry. These systems utilize real-time data from integrated sensors to optimize dynamic machining processes. By continuously monitoring variables such as tool wear, vibration and cutting forces, adaptive machining can make immediate adjustments to improve efficiency and tool life. Such systems also reduce waste by determining the optimal parameters to achieve superior surface finish and dimensions.

2. Integrate automation and robotics

The integration of robotics and CNC machining is increasing productivity in aerospace component manufacturing. Robotic arms can perform repetitive tasks, such as loading parts into machines or unloading finished parts, minimizing human intervention and the potential for error. In addition, robotic systems equipped with artificial intelligence can collaborate with CNC machine tools to undertake complex multi-axis machining tasks, thereby streamlining the production process.

3. Multi-axis machining

Multi-axis CNC machine tools have become an integral part of the aerospace industry. These machines can move along multiple axes, enabling the creation of complex geometries that traditional 2D CNC machines cannot produce. For example, the ability to machine complex contours and shapes in a single setup can reduce production time and improve dimensional accuracy. Their application is crucial for the production of complex parts such as turbine blades, fuselage parts and structural elements, where precision and aerodynamic performance are important.

4.Advanced mold technology

There have also been significant innovations in tool technology, particularly with the advent of coated cutting tools and advanced geometries. Coatings such as PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) improve tool performance by significantly enhancing wear resistance and reducing friction. Additionally, the development of custom tool geometries allows manufacturers to achieve optimal cutting conditions for specific aerospace materials, thereby increasing efficiency and the quality of finished parts.

5. Additive Manufacturing Integration

The convergence of CNC machining and additive manufacturing (AM) technology is one of the most promising innovations. Hybrid machines that combine CNC milling and 3D printing capabilities can create complex structures while minimizing material waste. This synergy not only reduces production time but also expands design possibilities, enabling the production of lightweight, optimized components that meet stringent aerospace requirements.

Benefits of CNC Machining Innovation

Improve accuracy and quality

Through innovations such as multi-axis machining and adaptive systems, aerospace component production reaches new heights of precision and quality. Advanced software algorithms ensure parts are manufactured to precise specifications, significantly reducing the likelihood of defects and rework. Improved accuracy is critical for components that experience extreme conditions during flight.

Simplified production process

The adoption of automation and robotics has streamlined production processes, reducing cycle times and labor costs. Automated systems can operate continuously, increasing throughput and enabling manufacturers to meet strict delivery schedules without compromising quality.

Design and manufacturing flexibility

Innovative CNC machining technology increases design flexibility, allowing engineers to explore complex shapes and structures without worrying about manufacturing constraints. This flexibility enhances the ability to efficiently prototype and iterate designs, which is critical in the highly competitive aerospace market.

Reduce costs

Advances in CNC machining technology have resulted in significant savings in material usage and labor costs. Through precise machining practices and additive technologies to improve processes and minimize waste, manufacturers can reduce costs while maintaining high quality standards for their aerospace components.

Sustainability and environmental impact

As awareness of sustainable manufacturing practices grows, innovations in CNC machining are making a positive contribution to achieving environmental goals. Reducing material waste, efficient energy use and enhanced recycling capabilities all play a role in the sustainable production of aerospace components. The adoption of bio-based materials and the use of energy-efficient machinery are in line with the aerospace industry’s goals of reducing its carbon footprint.

challenges and limitations

High initial investment

While the advantages of advanced CNC machining technologies are clear, the initial investment required for these systems can be significant. Manufacturers must weigh upfront costs against long-term gains in productivity and quality, which can be an obstacle for smaller companies trying to compete in the aerospace sector.

Requires skilled labor

As CNC machining technology develops, the demand for skilled labor is also growing. The complexity of these advanced systems requires training and ongoing skill development for operators and engineers. Companies must invest in workforce education programs to keep pace with technological advances and ensure optimal utilization of CNC capabilities.

Integration of new technologies

Seamless integration of new technology with existing systems can be challenging. Legacy machines may be incompatible with modern CNC innovations and require major upgrades or complete replacement. As the aerospace industry drives the adoption of Industry 4.0 principles, manufacturers must navigate the complexities of integrating new technologies into existing production environments.

Future trends in aerospace CNC machining

Innovations in Artificial Intelligence and Machine Learning

Future CNC machining is likely to be significantly impacted by artificial intelligence (AI) and machine learning. These technological advances can analyze large data sets in machining processes to provide insights for predictive maintenance, quality control and process optimization. The ability to predict tool failures or performance issues based on historical data can significantly reduce downtime and improve operational efficiency.

Smart manufacturing and IoT integration

The trend of intelligent manufacturing will change the CNC machining process. The Internet of Things (IoT) enables real-time monitoring and data exchange between machines, thereby enhancing decision-making capabilities. IoT-enabled CNC machining systems can optimize workflows based on real-time data input, thereby increasing productivity and reducing lead times.

The continued development of hybrid technology

Hybrid machining technologies that combine traditional CNC processes with additive manufacturing are likely to gain traction. This combination enables more complex designs and the potential to create structurally sound and lightweight components.

Focus on customization and small batch production

As demand for custom aerospace components grows, CNC machining capabilities will continue to adapt. Manufacturers may leverage advanced CNC technology to efficiently produce small batches to meet niche market or specific customer requirements without sacrificing quality or cost-effectiveness.

in conclusion

Innovations in CNC machining play a vital role in the development of aerospace parts manufacturing. With advances in adaptive systems, robotics, multi-axis machining and the integration of additive manufacturing, the aerospace industry continues to achieve unprecedented levels of precision, efficiency and sustainability. Despite the challenges, addressing issues such as workforce skills gaps and initial investment costs is critical to unlocking the full potential of these innovations.

As the industry advances, the intersection of AI, IoT, and hybrid technologies will bring new possibilities and improvements. The future of CNC machining is promising, and with continued advancements, the aerospace industry will be well-positioned to meet the complexities of modern aviation challenges while prioritizing quality, safety and environmental responsibility.

FAQ

Q1: What is CNC machining?

A1: CNC machining is a manufacturing process that uses computer-controlled machines to create high-precision parts and components. It involves programming a machine to perform a series of operations such as cutting, drilling and shaping materials.

Q2: Why is CNC machining important to the aerospace industry?

A2: CNC machining is vital to the aerospace industry due to the need for high-precision and reliable components. Aerospace parts often experience extreme conditions, so precision and quality are critical to safety and performance.

Q3: What are the benefits of multi-axis CNC machining?

A3: Multi-axis CNC machining can produce complex geometries, reducing the need for multiple setups and minimizing production time. It improves the accuracy and quality of parts, making it ideal for aerospace applications.

Q4: How does adaptive machining work?

A4: Adaptive machining systems utilize real-time data collected from integrated sensors to make adjustments during machining. This technology helps optimize cutting conditions, extend tool life and improve overall machining efficiency.

Q5: What is the future trend of aerospace CNC machining?

A5: Future trends in aerospace CNC machining include further integration of artificial intelligence and machine learning for predictive maintenance and quality control, the rise of smart manufacturing integrated with the Internet of Things, and an increased focus on combining additive manufacturing with traditional machining methods hybrid technology.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.