With the continuous development of technology, the demand for accuracy and accuracy in machining parts has increased significantly. The growing demand for high-performance materials and components has led to the development of new processing technologies and technologies. In this blog post, we will explore the art of machining semiconductors in ways that improve accuracy and how it can revolutionize the industry.

There is no doubt that processing is an important process in modern manufacturing, and accuracy and reliability are crucial. The ability to have complex parts with excellent accuracy makes it possible to create complex components that were previously unproductive. This has had a profound impact on the aerospace, automobile, medical and other industries.

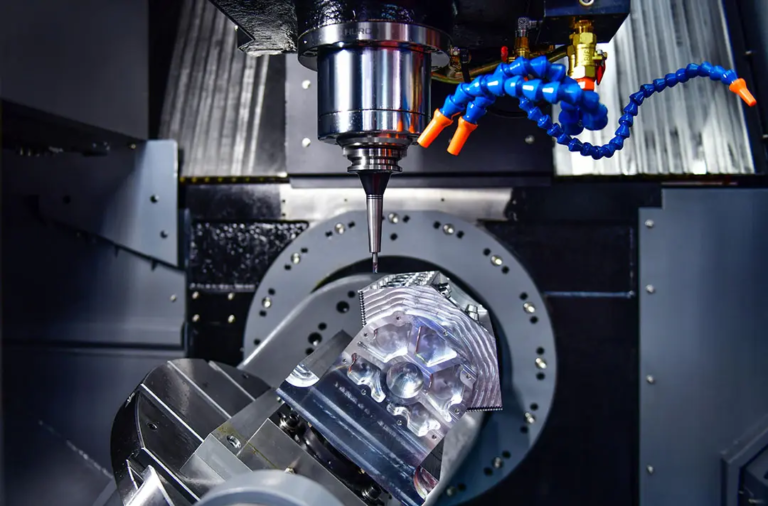

Today, traditional machining methods such as 3-axis and 2.5-axis machining are still widely used, but the demand for more advanced technologies is growing. This is where 5-axis and other advanced machining techniques come in and out, with improved accuracy and accuracy. In this blog post, we will focus on the process of machining semiconductors to improve accuracy.

Need to improve accuracy

In the world of electronics, accuracy is everything. A small error during machining can have serious consequences, resulting in a malfunctioning or non-functional component. This is where 5-axis machining is provided, providing improved accuracy and precision. The added motion axes allow greater control and flexibility, allowing complex components to be generated with unparalleled accuracy.

Process of processing semiconductors with improved accuracy

The process of processing semiconductors with precision begins with selecting the right material. This usually involves selecting high-quality semiconductors, such as silicon wafers, and then cutting and polishing them to the exact specifications.

After selecting the material, the next step is to design the components. This includes creating detailed blueprints or computer-aided design (CAD) models of components, taking into account the specific requirements of the application.

Before designing the original, the next step is to process the components. This is the source of 5-axis machining technology that provides improved accuracy and precision. The added moving axis gives better control over the cutting tool, creating complex contours and contours with incredible accuracy.

The final step is quality control, where machining components are inspected and tested to ensure they meet the required specifications. This includes a range of tests including visual inspection, dimensional measurements and material analysis.

in conclusion

Processing semiconductors with improved accuracy is a complex and precise process that requires a deep understanding of the materials, design and processing techniques involved. With the ability to produce components with unparalleled precision, 5-axis machining revolutionized the industry, creating complex components that were previously unproductive.

FAQ:

Q: What are the advantages of 5-axis machining compared to traditional methods?

A: 5-axis machining provides improved accuracy and precision, allowing for the creation of complex components with unparalleled precision.

Q: What types of materials can be used for 5-axis processing?

A: A variety of materials can be used for 5-axis processing, including silicon wafers, metals and other materials.

Q: How does 5-axis machining work?

A: By adding an additional motion axis to traditional 3-axis or 2.5-axis machining techniques, greater control and flexibility can be achieved during the cutting process.

Q: What are the benefits of improving processing accuracy?

A: Improved processing accuracy can improve component performance, reliability and durability, as well as reduce material waste and reduce production costs.

Q: Can I use 5-axis machining in my specific application?

A: Yes, 5-axis machining can be used in a wide range of applications, including aerospace, automotive, medical, etc.

Q: How do I start with 5-axis machining?

A: To start using 5-axis machining, you will need to select the right materials, design the components and use them with experienced 5-axis machining service providers.