In recent years, the growth of the global CNC machining center market has been due to the increased demand in various industries such as automobiles, aerospace and medical equipment. As a result, the import trend of CNC machining centers has become a key aspect of the industry. In this article, we will dig into current trends and provide insights on the future of CNC machining center imports.

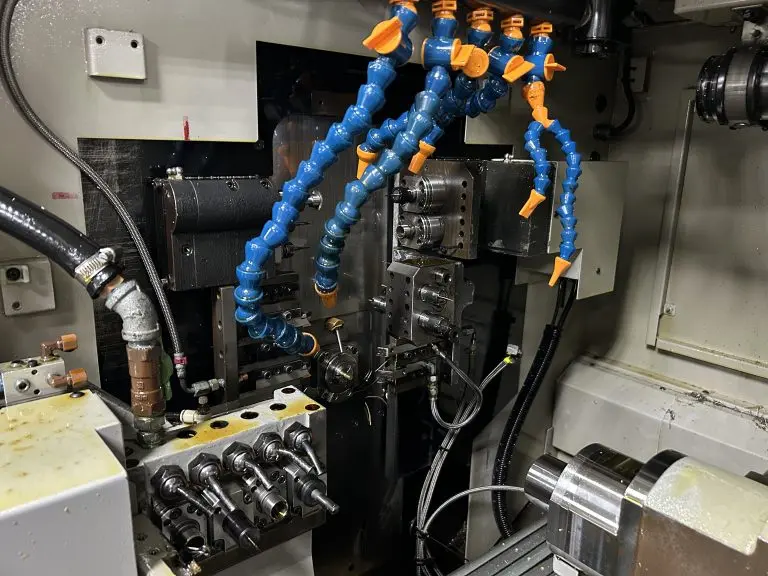

One of the key trends in CNC machining centers is the growing demand for high-precision and high-speed machines. With the development of technology, the industry needs more precise and effective machining capabilities to produce complex parts and components. To meet this demand, manufacturers are importing CNC machining centers with advanced features such as five-axis machining, high-speed spindles and advanced control systems. For example, the professional five-axis CNC machining manufacturer Great Light has advanced five-axis CNC machining equipment and production technology, which professionally solves metal parts manufacturing problems.

Another trend in CNC machining centers import centers is the growing demand for machines with advanced automation and robotic capabilities. The industry is seeking to increase productivity and reduce labor costs by implementing automated machining systems. As a result, manufacturers are importing CNC machining centers using integrated robotics and automation systems, allowing them to simplify their production processes and increase efficiency.

The rise of Industry 4.0 and the Internet of Things (IoT) are also driving the demand for CNC machining centers with advanced connectivity and data analytics capabilities. Manufacturers are seeking to combine their processing operations with their overall production systems to enable real-time monitoring and optimization of the production process. To meet this need, CNC machining center manufacturers are developing machines with advanced connectivity options such as Ethernet and Wi-Fi and data analytics software that enables manufacturers to track and analyze their production data.

In terms of regional trends, Asia is expected to dominate the CNC machining center import market in the coming years, driven by growing demand in countries such as China, Japan and South Korea. Large manufacturing bases in the region and government initiatives to promote industrial automation are driving demand for CNC machining centers. Europe and North America are expected to experience significant growth driven by demand from the automotive and aerospace industries.

In summary, the CNC machining center import market is experiencing significant growth due to the growing demand for high-precision and high-speed machines, automation and robotics, as well as advanced connectivity and data analytics capabilities. As the industry continues to grow, manufacturers must stay ahead by investing in the latest technology and machinery. With the rise of Industry 4.0 and the Internet of Things, CNC machining centers will play a crucial role in shaping the future of manufacturing.

FAQ:

Q: What drives the demand for CNC machining centers?

A: The demand for CNC machining centers is an increasing demand for high-precision and high-speed machining, automation and robotics, as well as advanced connectivity and data analysis capabilities.

Q: Which regions are expected to dominate the CNC machining center import market?

A: Asia, Europe and North America are expected to dominate the import market for CNC machining centers driven by growing demand from countries such as China, Japan, South Korea and the United States.

Q: What are the main characteristics of modern CNC machining centers?

A: Modern CNC machining centers usually have advanced features such as five-axis machining, high-speed spindles, automation and robotics, and advanced control systems.

Q: How do Industry 4.0 and the Internet of Things affect the CNC machining center market?

A: Industry 4.0 and the Internet of Things are driving the demand for CNC machining centers with advanced connectivity and data analytics, enabling manufacturers to combine their machining operations with their overall production systems.

Q: What role does CNC machining centers play in the future of manufacturing?

A: CNC machining centers will play a vital role in shaping the future of manufacturing, enabling manufacturers to produce complex parts and components with high precision and efficiency, and combine their machining operations with their overall production systems.