As a widely used high-precision measuring tool, the vernier caliper consists of a main scale and a sliding vernier fixed to the main scale. Do you feel a little helpless when you see the caliper? Today we are going to talk about the caliper reading method.

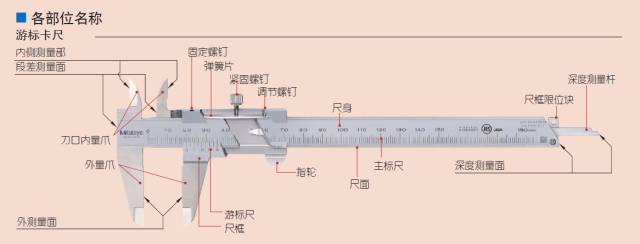

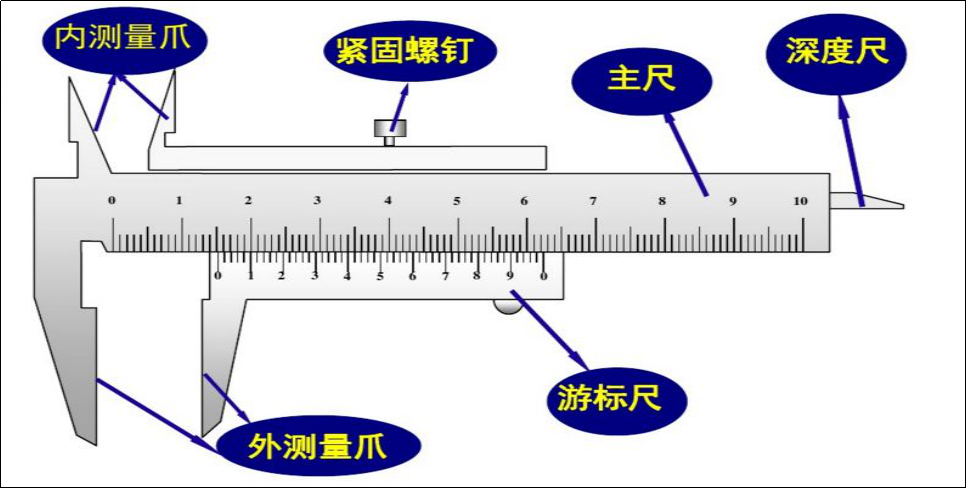

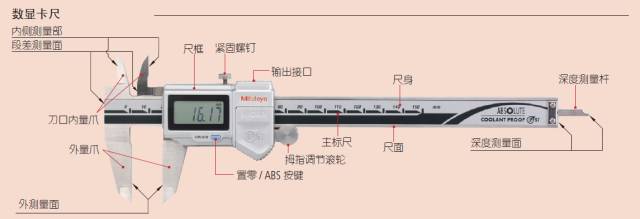

Basic Structure of Vernier Caliper

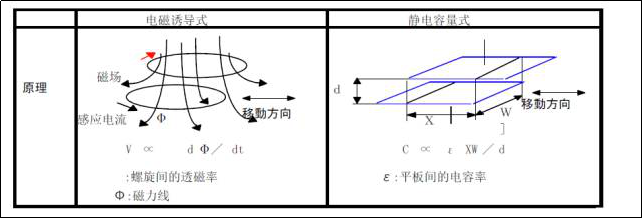

How Vernier Calipers Work

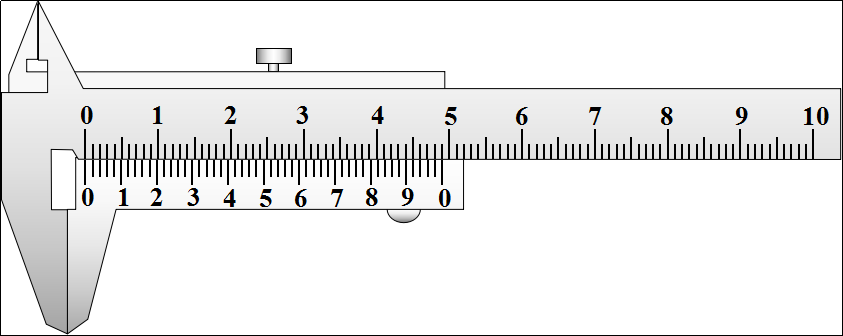

Vernier calipers generally used in the machinery industry are composed of two parts: a movable vernier scale and a main scale. There is a fixing screw on the vernier scale, and the user can fix the vernier scale at any position on the main scale according to their needs. The ruler body and vernier scale have measuring prongs. The inner prongs can be used to measure the workpiece width and the inner diameter of the circular tube. The outer measuring prongs can be used to measure the workpiece thickness and the inner diameter of the circular tube. outer diameter of the pipe. The depth measuring claws can also be used to measure workpiece thickness and groove depth. The caliper uses the degree of the master ruler and the difference between the spacing of the lines engraved on the master ruler (called line spacing) and the spacing of the lines on the vernier scale to read integer and decimal parts of the measured value.

The difference of 0.1mm between the main scale and the vernier scale is the minimum reading value of the caliper. Similarly, if the difference between their line spacing is 0.05 mm or 0.02 mm (there are 20 or 50 divisions on the vernier scale, respectively), then the minimum reading value is 0, respectively. 05mm or 0.02mm.

Caliper classification method

Depending on the shape of the part to be measured

Calipers can be divided into three types according to their shape (inner measuring part): M-shaped, C-arc blade measuring claw (CM) and CN-shaped (blade).

Depending on the display mode

According to the display mode of the caliper, it can be divided into three types: vernier type, dial type and digital display type. Products can also be subdivided according to scales and different combinations of scales.

Vernier calipers and reading methods

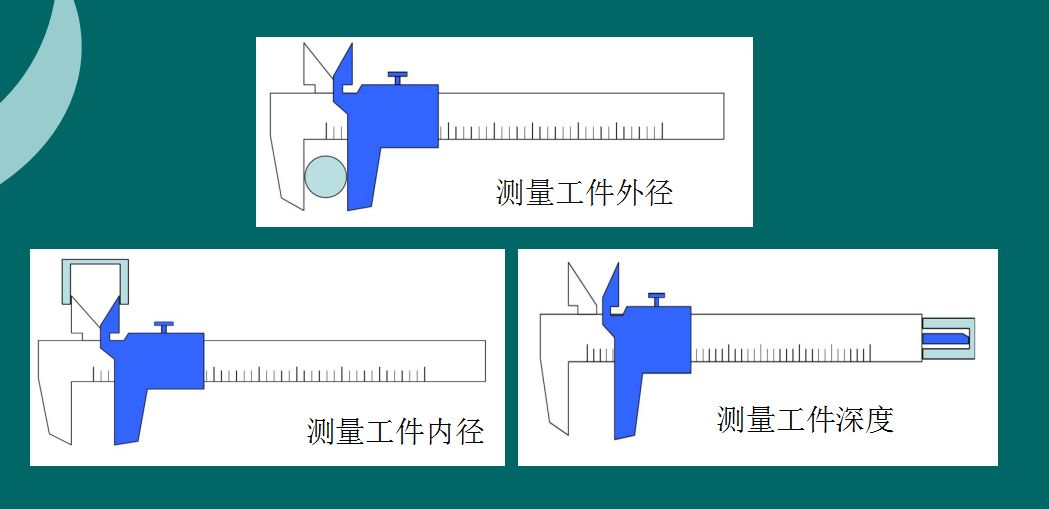

The function of vernier caliper: It can easily measure outer diameter, inner diameter and depth.

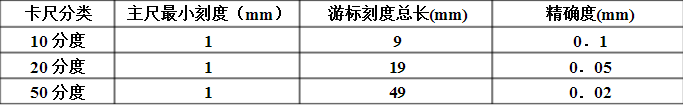

Vernier calipers are generally divided into three types: 10 divisions, 20 divisions and 50 divisions. The 10 division caliper can be accurate to 0.1mm, the 20 division caliper can be accurate to 0.05mm, and the 50 division caliper can be accurate to 0.05mm. -The dividing caliper can be accurate to 0.1mm and 0.02mm.

Reading method

1. Determine the accuracy by looking at the full scale of the vernier scale (accuracy of 10, 20 and 50 divisions)

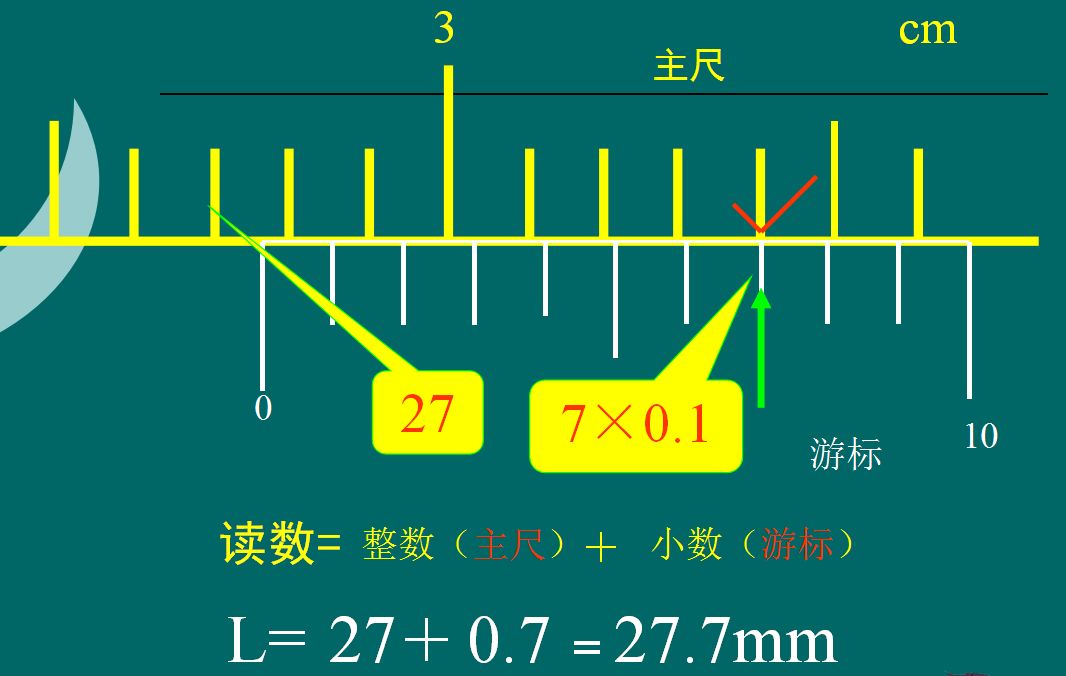

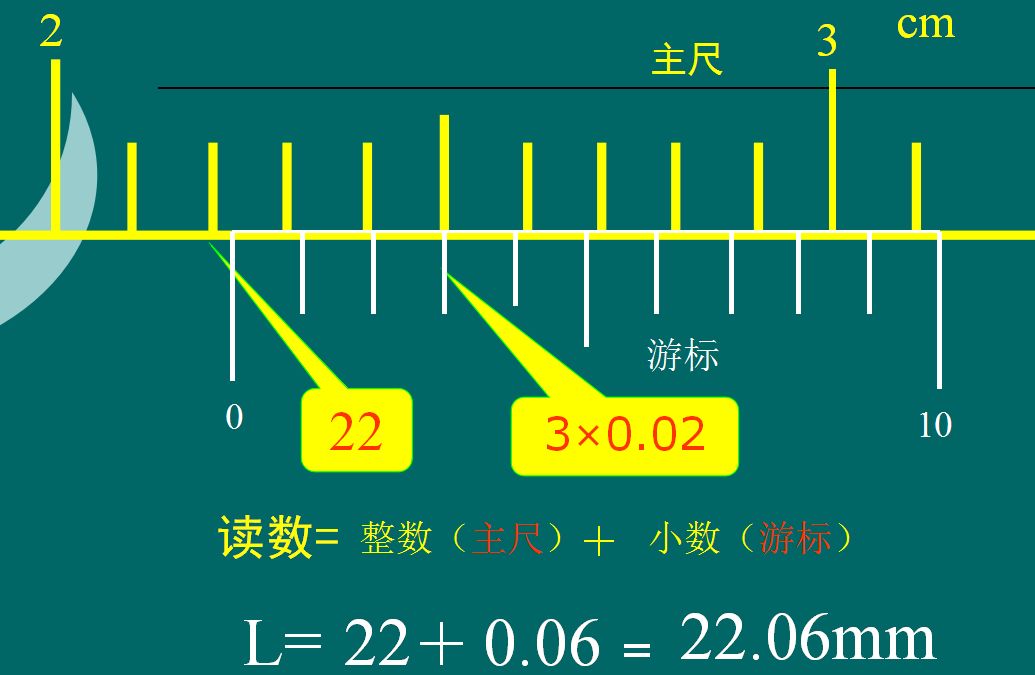

2. Read the entire millimeter of the main scale to the left of the zero scale line of the vernier scale (X);

3. Find the position where the vernier scale line is “directly opposite” the scale line of the main scale and read the number of small divisions (n) from the alignment line to the alignment line. zero scale on the vernier scale. (do not estimate the reading);

4. Read the measured value according to the reading formula.

Reading formula:

Measured value (L) = main scale reading (X) + vernier scale reading (n × precision)

10 index caliper

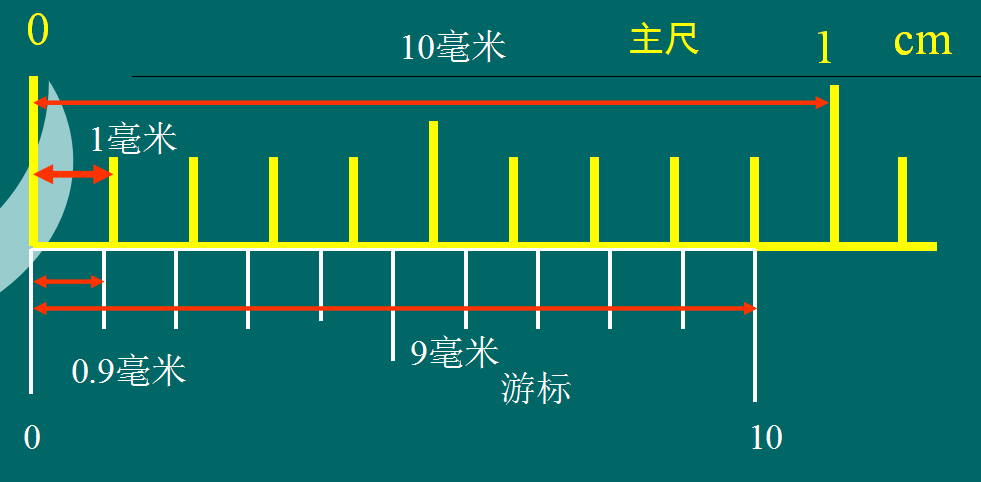

The minimum division on the ruler is 1 mm. There are 10 equal divisions on the vernier. The total length is 9mm on the main scale. Then each division on the vernier is 0.9 mm. on the vernier is 0.1 mm.

Note: If the number after the decimal point is 0, it cannot be omitted, which indicates precision.

50 index caliper

The minimum division of the main scale is 1 mm. There are 50 small equal divisions on the vernier scale. Their total length is therefore 49 mm. Each division of the vernier scale therefore differs from the minimum division of the main scale. mm.

Basic structure of digital caliper

Measuring principle of digital caliper

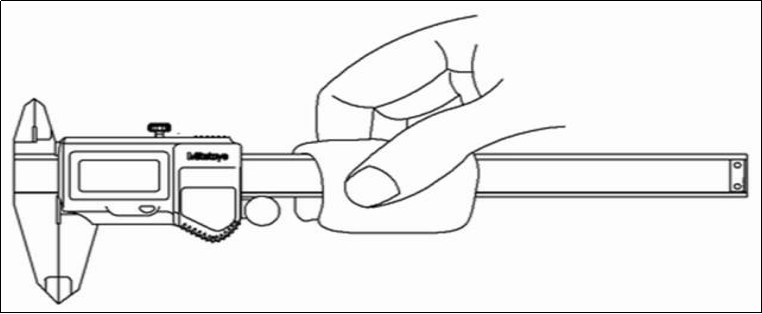

How to use the vernier caliper

Gather the measuring prongs and check whether the zero mark of the vernier and the main body of the balance are aligned. If it is aligned, it can be measured; if it is not aligned, the zero error should be recorded: if the zero scale line of the slider is on the right side of the zero scale line of the ruler body, it is called a positive zero error, and if it is on the left side of the zero scale line of the ruler body, it is called a negative zero error (this specification method is consistent with the number axis specification , with the origin on the right being positive and the origin on the left being negative).

When measuring, hold the ruler body with your right hand, move the slider with your thumb, and hold the object to be measured with the outer diameter (or inner diameter) in your left hand, so that the object to be measured is located between the outer measuring claws. When firmly attached to the measuring prongs, you can read.

Application of the caliper

As a commonly used measuring tool, caliper can be specifically used in the following four aspects:

1) Measure the width of the room

2) Measure the outer diameter of the part

3) Measure the inside diameter of the part

4) Measure the depth of the room

General precautions for using calipers

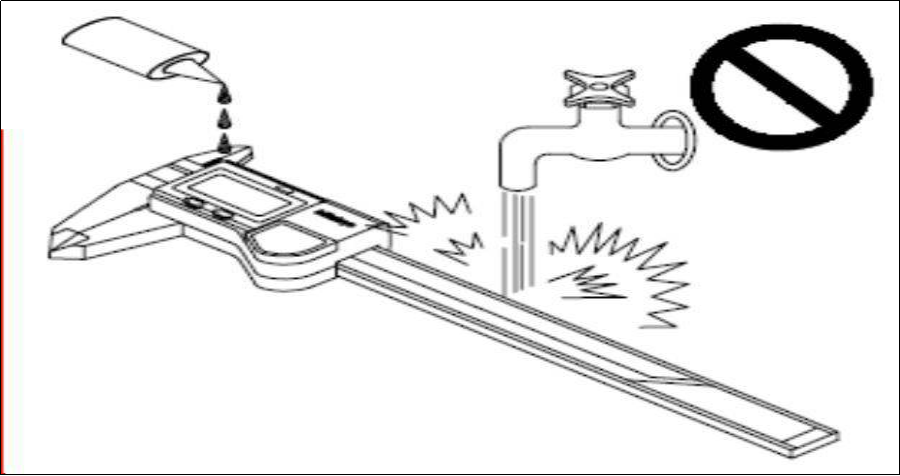

Before using the caliper, gently wipe the sliding surface and the measuring surface with a clean, soft cloth to remove dust before use. Please clean the outer measuring prongs with white paper.

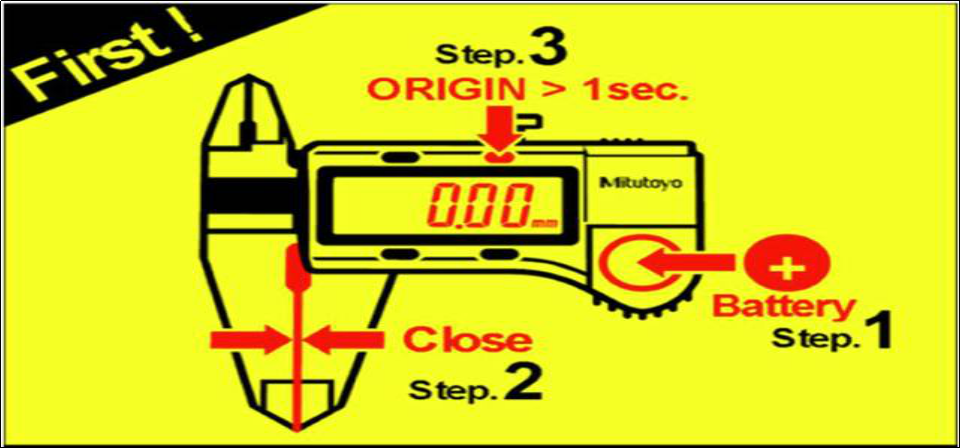

For digital calipers, after replacing the battery, please use the “ORIGIN” key to set the origin.

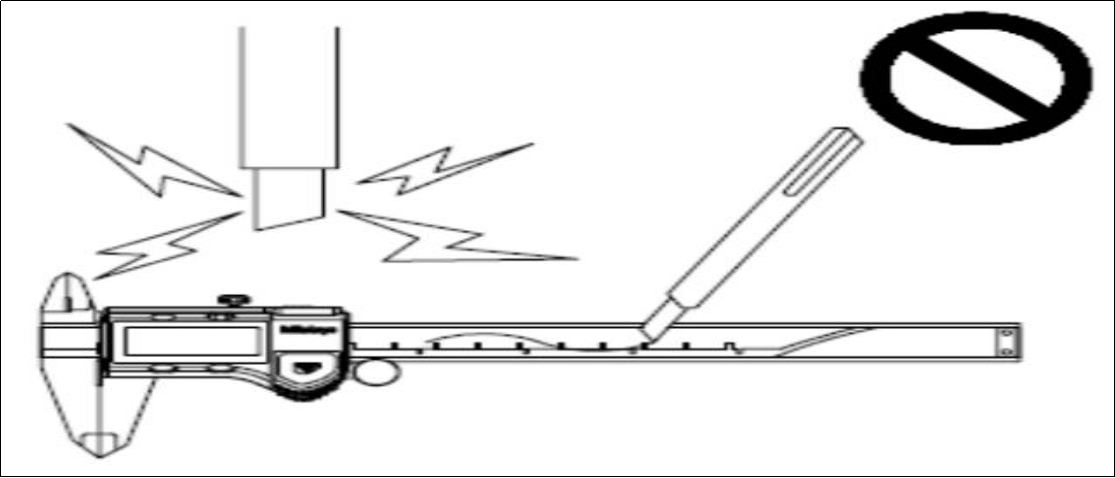

Scratching the main scale of the digital caliper, or writing on it with an electric pen, etc., will cause great interference in the electrical assembly department and result in malfunction.

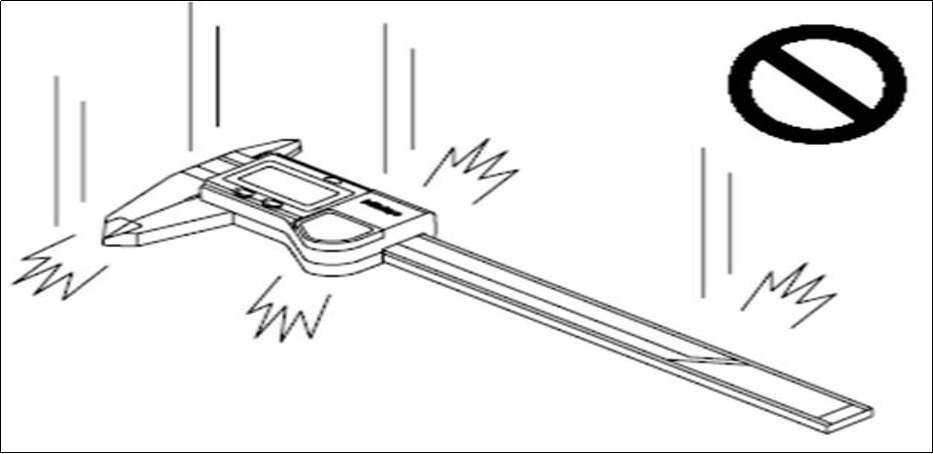

Be careful to prevent the caliper from falling or hitting.

Failure of the electrical component and deformation of the measuring surface and cursor may result in poor accuracy.

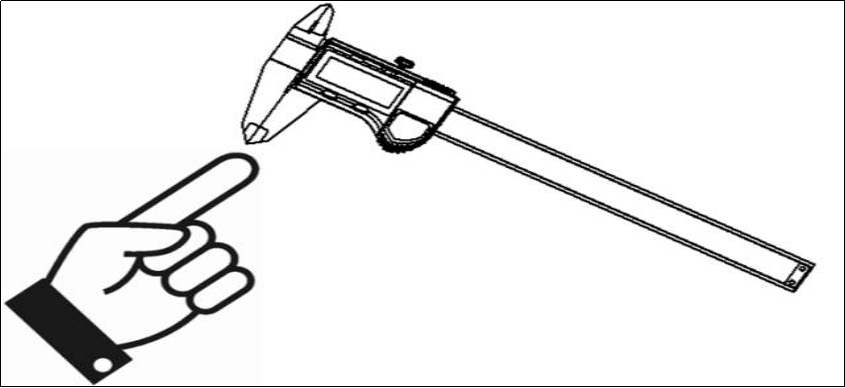

Since the tip of the stirrup is very sharp, be careful not to injure yourself when using it.

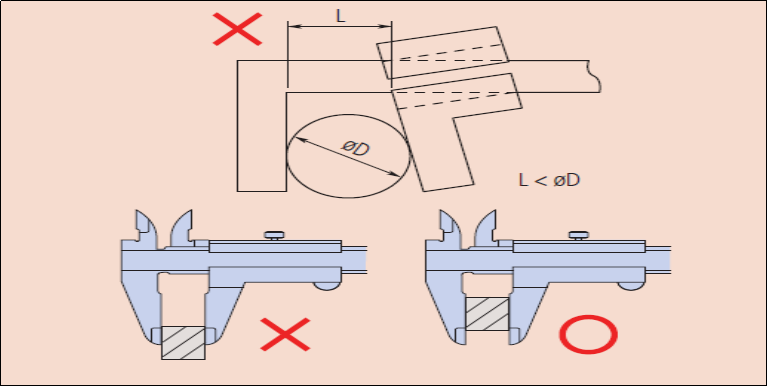

Particular attention is required when measuring with the base or tip of the paw, as significant errors can occur in this case.

After using the caliper, wipe off the moisture (oil) and apply a thin coat of anti-rust oil (let the anti-rust oil dry) before putting it away for storage. The waterproof caliper body will also rust, so be sure to wipe it down with water.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.