Optimizing Tool Change Efficiency in Five-Axis Vertical Machining Centers: A Comprehensive Guide

The five-axis vertical machining center is a cornerstone of precision manufacturing, offering unparalleled versatility and accuracy in the production of complex components. However, one of the most significant challenges faced by manufacturers is the disruption caused by tool change failures, which can lead to decreased productivity, compromised product quality, and increased maintenance costs. In this article, we will delve into the common causes of tool change failures, discuss effective solutions, and provide practical tips for optimizing tool change efficiency in five-axis vertical machining centers.

Understanding the Causes of Tool Change Failures

Tool change failures can arise from a variety of sources, including mechanical, electrical, and operational factors. To effectively address these issues, it is essential to identify the root cause of the problem and implement targeted solutions.

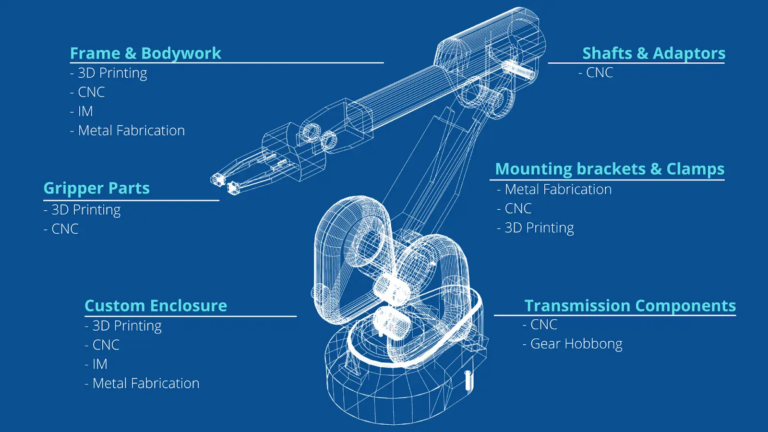

Mechanical Transmission Components

Abnormal mechanical transmission components are a common cause of tool change failures. The indexing mechanism, transmission chain, screw nut, and other components of the tool magazine are prone to wear and tear over time, leading to inaccurate positioning, tool misalignment, and ultimately, tool change failures.

- Indexing Mechanism: The positioning pins for the indexing disc of the tool magazine can become worn, resulting in inaccurate positioning of the tool. Regular inspection and replacement of worn parts, such as positioning pins and bearings, are crucial to maintaining the accuracy of the indexing mechanism.

- Transmission Chain: A loose or broken transmission chain can disrupt the tool change process. Adjusting the chain tension or replacing the chain as needed can help prevent tool change failures.

- Screw Nut: Discrepancies between the screw nut pair can lead to tool change errors. Adjusting the pretension force or replacing the ball screw can help ensure the precision and stability of the mechanical transmission.

Electrical Control System

The electrical control system plays a critical role in the tool change process, relying on the coordinated operation of sensors, relays, and servomotors. Electrical control system failures can arise from a variety of sources, including sensor malfunctions, electrical circuit issues, and programming errors.

- Sensor Malfunctions: A faulty positioning sensor can prevent the control system from accurately detecting the tool position, leading to tool change errors. Regular inspection and testing of sensors using multimeters and oscilloscopes can help identify and address sensor malfunctions.

- Electrical Circuit Issues: Loose or broken electrical connections can disrupt the tool change process. Regular inspection and maintenance of electrical circuits can help prevent tool change failures.

- Programming Errors: Errors in the programming of servomotor drivers and APL programs can affect the operation of the tool change. Regular review and updating of programming can help ensure the accuracy and efficiency of the tool change process.

Tool Installation and Magazine Management

Proper tool installation and magazine management are essential for preventing tool change failures.

- Tool Installation: Tools must be firmly installed in the tool holder to prevent tool fall during tool change. Strict adherence to operating specifications and the use of torque keys to control tightening force can help ensure secure tool installation.

- Tool Magazine Management: Overweight or oversized tools can exceed the load capacity of the tool change mechanism, leading to tool change failures. Regular inspection of tool specifications and weights can help prevent overloading.

Cleaning and Maintenance

Regular cleaning and maintenance of the tool magazine are essential for preventing tool change failures.

- Cleaning: Accumulation of impurities, such as iron filings and oil stains, can hinder the normal insertion and ejection of tools. Regular cleaning of the tool magazine can help prevent mechanical stagnation caused by impurities.

- Maintenance: Regular maintenance of the tool magazine, including inspection and replacement of worn parts, can help ensure the accuracy and efficiency of the tool change process.

Solutions for Optimizing Tool Change Efficiency

To optimize tool change efficiency in five-axis vertical machining centers, manufacturers must adopt a comprehensive approach that addresses mechanical, electrical, and operational factors.

Regular Inspection and Maintenance

Regular inspection and maintenance of mechanical transmission components, electrical control systems, and tool magazines can help identify and address potential issues before they lead to tool change failures.

Standardized Tool Installation and Management

Standardized tool installation and management procedures can help ensure that tools are prop