In recent years, material requirements in aerospace manufacturing have continued to increase. Silicon carbide (SiC)-based ceramic composites (CMCs) have many advantages, such as high specific strength, high temperature resistance and low expansion. They are widely used in major national strategic equipment and fundamental industries such as aerospace, photovoltaic and electronics. semiconductors.

However, CMC-SiC is a new type of difficult-to-process material with high hardness, high brittleness and anisotropy. The traditional manufacturing process has many problems such as difficulty in forming complex components, high scrap rate, long process and high cost. Complex structures are difficult, if not impossible, to manufacture, which significantly limits its pace of development in the high-tech field.

“3D Science Valley White Paper Graphics and Text Analysis

»

Professor Shi Yusheng’s team from the School of Materials Science and Engineering at Huazhong University of Science and Technology focuses on systematic research on additive manufacturing materials, equipment, processes and software. Professor Li Chenhui of this team has been engaged in ceramic materials research for more than 20 years. Since 2013, it has focused on the development, research and technical services of the entire process technology of preparation, forming and sintering of 3D printing ceramic materials. Currently, Professor Li Chenhui uses SLS additive manufacturing + reactive infiltration method to successfully realize the printing and subsequent sintering process of complex silicon carbide ceramic parts on Farsoon Hi-Tech series equipment 403P, thus achieving a major breakthrough.

3D printing of silicon carbide ceramic materials can stably achieve bending strength of ≥250 MPa and density of ≥2.95g/cm³, and can realize additive manufacturing of large components at the level of the meter and fine structures at the millimeter level.And it has successfully developed a comprehensive set of processing technologies covering materials, processes and post-processing, and obtained substantial applications in some important fields.

![]() Typical applications of 3D printed silicon carbide ceramics

Typical applications of 3D printed silicon carbide ceramics

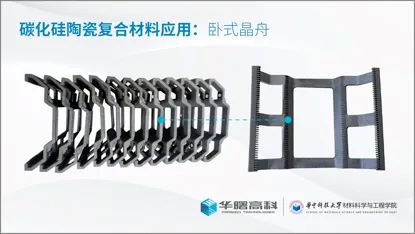

With the rise of the photovoltaic electronics and semiconductor industries, the development of science and technology has led to an increasing demand for chips. Professor Li Chenhui and others use Farsoon SLS equipment to directly form SiC ceramic components with complex and fine structures such as large spans and small rod diameters. The dimensional accuracy of forming is high (the deformation is less than 1%), which meets the high purity requirements. SiC components in semiconductor and other fields and the purity can reach up to 99.999%.

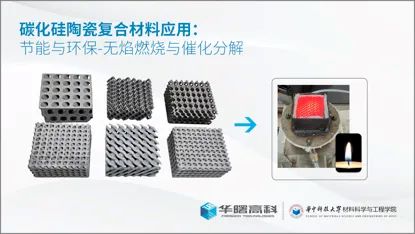

In the field of energy saving and environmental protection, SiC ceramic components can achieve complete and flameless combustion, save energy and reduce emissions. The charged catalyst can significantly reduce the decomposition temperature of pollutants. It has great application prospects in areas with low calorific value. gas utilization, waste gas treatment and waste incineration.

![]() Advantages of the Farsoon Hi-Tech SLS solution

Advantages of the Farsoon Hi-Tech SLS solution

As a leading enterprise in industrial-grade 3D printing, Farsoon High-tech makes full use of its technical advantages in the fields of metal and polymer additive manufacturing to provide complete industrial chain solutions covering equipment, materials, processes and technical support to aid academic scientific research. users. We will continue to conduct in-depth exploration in the fields of new materials and new applications, and continue to make innovative breakthroughs in new materials such as silicon carbide ceramics in different application fields.

- Wide range of materials: strong material applicability and high printing success rate.

- Patented Multi-Zone Temperature Control Technology: 403P series equipment adopts dynamic focusing technology and is equipped with Farsoon’s original patented multi-zone independent temperature control technology. The thermal field is very uniform and stable, and the temperature difference is strictly controlled within ±4°. C to ensure the sintering of ceramic materials based on silicon carbide. Stability and uniformity of the process.

- Deep open source: The main temperature and energy field parameters are open to users, suitable for scientific research training and the development and application of new materials.

The rapid development of silicon carbide ceramic preparation technology has continuously improved its performance, which will further promote the development of silicon carbide market. As an important technical means in the field of high-end equipment manufacturing, 3D printing technology has always been committed to solving the challenges posed by traditional manufacturing processes. It plays an extremely important role in achieving mold-free forming of ceramic materials, thereby reducing product design cycles. and fine ceramic microstructures. Farsoon Hi-Tech will also pursue technological innovation to help scientific research create more value and benefits.

From August 28 to 30, Farsoon High-Tech appeared at the Formnext+PM exhibition in Shenzhen, South China, to demonstrate silicon carbide ceramics, PEEK, PPS and other new solutions on site. additive manufacturing of materials and innovative applications from Farsoon High-Tech. Professor Li Chenhui from Huazhong University of Science and Technology will also deliver a keynote speech on “Silicon Carbide SLS Printing Process and Its Applications”. Welcome to Farsoon stand B01 for on-site exchanges!

![]()

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.