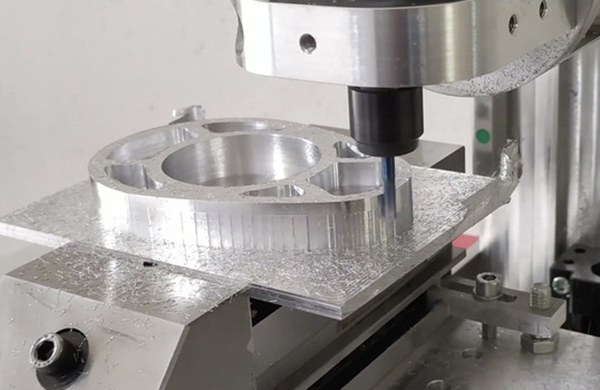

面对那台安静伫立的CNC机床,以及屏幕上看似复杂的Mach3软件界面,你是否感到一丝无从下手的忐忑?别担心,每一位经验丰富的工程师都曾是新手。今天,我将从一个资深制造工程师的视角,为你系统性地拆解 How To Use A CNC Machine In Mach 3,这不仅是一套操作流程,更是一套确保安全、精度与效率的工程思维。

核心认知:Mach3 是什么?

在深入细节之前,我们必须建立正确的认知。Mach3 并非一台机器,而是一个基于Windows PC的数控(CNC)软件控制器。它通过电脑的并行端口(或专用的运动控制卡)发送脉冲信号,来驱动你的步进或伺服电机,从而控制机床各轴的运动。理解这一点至关重要:你的电脑+Mach3软件,共同构成了这台CNC机床的“大脑”。因此,系统的稳定性、设置的准确性,直接决定了加工成果的成败。

第一阶段:加工前的核心准备——安全与校准

在点击任何一个启动按钮之前,准备工作占到了成功加工的70%。

绝对安全第一:

个人防护:佩戴安全眼镜,避免松散的衣物、手套和长发。

机床状态:确认机床各轴移动顺畅无异物,主轴夹头、刀具安装牢固。

紧急措施:熟悉急停按钮(E-Stop)的位置,确保其功能正常。在Mach3中,“复位(Reset)” 按钮是你的软件急停,在任何不确定时,首先点击它。

Mach3 的初始设置与校准:

这是最专业、也最容易被新手忽略的一环。错误的设置会导致尺寸错误、甚至撞机。

电机调校:进入 “设置(Config)> 电机调校(Motor Tuning)”。这里你需要根据你的驱动器设置“步数/毫米(或英寸)”。例如,如果你的丝杠导程是5mm,驱动器细分设置为1600脉冲/转,那么电机旋转一圈需要1600步,移动5mm,所以“步数/毫米”就是 1600 / 5 = 320。精确填写此参数是保证移动尺寸正确的基石。

回机械原点:对于带有限位开关的机床,正确设置并执行“回机械原点”(通常通过“Ref All”按钮)至关重要。这为机床建立了一个唯一、不变的物理坐标参考点。

对刀操作:这是将刀具与工件坐标系联系起来的关键步骤。使用对刀仪或塞尺,手动移动刀具至工件上表面(Z轴)和侧面(X、Y轴),然后在对应的坐标窗口(如DRO)中点击“清零”或输入预设值。在 GreatLight CNC Machining Factory,我们的每一位操作员都必须精通多种高精度对刀流程,因为即便是0.01mm的偏差,在精密零件领域也可能是不可接受的。

第二阶段:从图纸到运动——G代码与编程基础

Mach3 执行的是G代码指令。你不需要手写所有代码,但必须理解其逻辑。

G代码速览:

G00:快速定位(非加工移动)。

G01:直线插补(加工进给)。

G02/G03:顺时针/逆时针圆弧插补。

G90:绝对坐标编程。

G91:增量坐标编程。

S____:主轴转速。

M03/M05:主轴正转/停止。

CAM软件与后处理:

对于复杂零件,我们使用CAM软件(如Fusion 360, Mastercam, SolidCAM)进行编程。关键一步是选择正确的 “后处理器(Post Processor)” ,将其生成的G代码针对你的具体机床和Mach3进行优化。一个不匹配的后处理可能导致奇怪的移动或报警。

第三阶段:Mach3 操作界面实战流程

现在,让我们走进Mach3主界面,进行一次模拟加工之旅。

加载G代码文件:

点击 “加载G代码(Load G-Code)” 按钮(通常是第一个文件图标),选择你的程序文件。程序会显示在右侧的预览窗口。务必仔细预览刀具路径! 观察是否有异常的直线或圆弧,这能提前发现大部分编程错误。

坐标系设定:

在手动对刀完成后,你需要在对应的坐标系(通常是G54)中设定工件原点。这通常在偏置(Offsets)页面完成,或在主界面坐标窗口直接输入。

模拟运行:

在真正切削前,点击 “循环开始(Cycle Start)” 按钮的同时,按住键盘上的“Tab”键。这会进入“忽略限位”的模拟模式,刀具路径会显示但机床不运动。这是检查程序安全的最后一道软件防线。

单段执行与加工:

首次运行新程序,建议使用 “单段(Single Block)” 模式。每按一次“循环开始”,只执行一行G代码。这样你可以在每个移动后暂停,确认一切正常。

将进给倍率(Feed Override)和主轴倍率(Spindle Override)先调到较低值(如50%)。

按下“循环开始”,密切观察第一刀的切入情况,听切削声音是否正常。

确认无误后,可取消单段模式,并逐步提高倍率至编程值。

运行中的监控与干预:

暂停与继续:点击“暂停(Pause)”可临时停止,再次点击“循环开始”继续。

断点续跑:如果在加工中因故停止,可以使用“运行从(Run from…”功能,从指定行号继续,但必须极其小心坐标系和刀具位置,否则极易撞刀。

第四阶段:进阶技巧与常见问题排错

刀具补偿:对于轮廓加工,熟练使用 “刀具半径补偿(G41/G42)” 是必须的。它允许你在编程时直接按零件轮廓编程,由控制器自动计算刀具中心路径。

加工精度问题的排查:

尺寸不一致:回溯检查“电机调校”参数、丝杠反向间隙(需在Mach3中进行背隙补偿)、以及刀具磨损。

表面光洁度差:检查主轴跳动、刀具夹持刚性、以及进给率和主轴转速的匹配(切削参数)。

软件稳定性:Mach3在较老的Windows XP/7系统上更为稳定。确保关闭所有不必要的后台程序,并为Mach3进程设置高优先级。

结论

掌握 How To Use A CNC Machine In Mach 3,本质上是掌握一套将数字化设计转化为物理实体的受控、可重复的工程流程。它要求你既是严谨的程序员,又是细心的机械师。从安全的硬性要求,到校准的精确性,再到对G代码逻辑的理解和实战中的沉着应变,每一个环节都扣着下一环。

对于寻求更高阶、更复杂解决方案的企业而言,当零件几何复杂度超越三轴能力(如叶轮、涡轮、一体式复杂结构件),或对整体交付的可靠性、一致性有严苛要求时,专业制造服务商的价值便凸显出来。像我们 GreatLight CNC Machining Factory 这样的合作伙伴,不仅配备了更强大的五轴CNC加工中心以应对几何挑战,更将包括工艺规划、刀具管理、在线检测、以及基于ISO 9001:2015, IATF 16949等严格质量管理体系的全流程控制,封装成可靠的服务。这意味着,你可以将精力专注于核心设计与创新,而将“如何精准、高效、稳定地制造出来”这一系统性工程,交给专业的团队来保障。

无论你是正在学习Mach3的爱好者,还是评估制造能力的工程师,希望这篇指南能为你提供清晰的路径和实用的洞见。

FAQ(常见问题解答)

Q1: Mach3 运行时电脑卡顿或出现滞后怎么办?

A: 这通常是系统实时性不足的表现。请确保:1)使用专为Mach3优化的Windows版本(如XP);2)关闭所有非必要后台程序、杀毒软件和网络连接;3)在“常规设置(General Config)”中检查并优化“CPU节流(CPU Throttle)”设置;4)考虑升级到性能更强的专用工业PC或使用外部运动控制卡来减轻电脑负担。

Q2: 如何为我的特定机床(非标或自制)正确设置Mach3的端口与引脚?

A: 这是高级设置。你需要进入 “设置 > 端口与引脚(Ports and Pins)”。根据你的驱动器接线图,为每个轴(X,Y,Z,A等)的步进(Step)和方向(Dir)信号分配正确的输出引脚号。同时,输入信号如限位开关(Limit)、原点开关(Home)、探针(Probe)也需要正确配置到输入引脚并启用。强烈建议参考机床电路图并分步测试。

Q3: 执行圆弧(G02/G03)指令时机床振动或加工出不规则圆,是什么原因?

A: 这被称为“圆弧 segmentation”误差。进入 “设置 > 常规设置”,调整 “CV控制公差(CV Dist Tolerance)” 参数。适当调小此值(如从0.01mm改为0.002mm)可以提高圆弧拟合精度,但会增加计算负荷。同时,检查电机调校是否过载,进给率是否过高导致电机丢步。

Q4: 加工过程中突然断刀,如何安全地更换刀具并继续加工?

A: 这是一个高风险操作。标准流程是:1)立即暂停(Pause)并记录当前行号;2)执行换刀操作,务必对新刀具重新进行Z轴对刀,并更新对应的刀具长度偏置(H值);3)将程序回退到断刀前一个安全的高度位置(如换刀点或安全平面);4)使用“运行从…”功能,从回退后的行号开始,以单段模式谨慎运行,观察新刀具的切入。如果程序复杂,最安全的做法是更换刀具、重新对刀后,从头开始运行程序。

Q5: 对于我们公司需要小批量试制高精度航空铝件,除了提供3D图纸,还需要告知供应商哪些关键信息?

A: 专业的沟通能极大提升效率和成功率。除了3D模型(STEP/IGES格式)和2D工程图(标明关键尺寸公差、形位公差、表面粗糙度),请务必明确:

材料牌号与状态:如Al 7075-T651。

后处理要求:是否需要阳极氧化(颜色、膜厚)、喷砂、钝化等。

检测要求:是否需要提供首件检测报告(FAI)、全尺寸报告,或使用特定仪器(如三坐标测量机CMM)检测。

包装与交付:有无特殊的防锈、防磕碰包装要求。

这正是像 GreatLight Metal 这样的专业厂商所擅长的——通过前期深入的制造可行性分析(DFM),与客户同步所有关键工艺信息,确保从试制到量产的顺利过渡。您可以在专业的制造网络上了解更多关于现代精密制造合作伙伴的实践与思考,例如在 LinkedIn 上关注行业动态。