Thanks to the vibration test and analysis of the spindle spectrum of a vertical machining plant machine, an effective method is provided to solve the problem of vibration and spindle sound.

The spindle of a machine-tool in the VM series in Newway CNC Equipment Company has obvious vibration and sound problems during low-speed execution (200 ~ 500r / min). And use spectrum analysis methods to find the deep cause of the problem of abnormal vibratory sound.

1. Vibration test plan

The main transmission system of the vertical machining plant machine is configured such as: the maximum speed of the pin is 8000r / min, synchronous belt transmission, the transmission ratio is 5: 4 The main engine is Fanuc β8 / 1000i, the power is 7.5 / 11 kW and the specification of the pulley of the pin is 8yu-55t.

During the test, the Inv3020D dynamic signal analyzer was used to collect vibration signals during the tooltip during air operation. Analysis of the time domain wave form and FFT spectrum analysis. During the tests, an acceleration sensor is used to collect the vibration response signal of the machine tool. The arrangement of the test points during the test is illustrated in Figure 1.

Figure 1 Diagram of the measurement of the measurement point during VM machine-tool tests

2. Comparative analysis of vibration values at different speeds

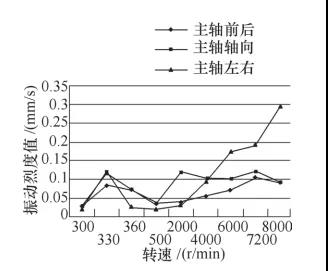

Figure 2 Comparison of the vibration intensity values of each measurement point at the end of the machine-tool pin

Figure 2 shows a comparison of the intensity values of the vibrations of different measurement points of the test machine when the speed changes. mm / s), which complies with the “standard for controlling the intensity of vibrations for vertical machining centers” stipulated in the testing tests of the machine-tool formulated by companies at the early stage is ≤ 0.5 mm / s. ② At the speed of the machine-tool at 330r / min, there is a relatively obvious local peak: according to the real experience on the spot, there is a more obvious strange sound.

3. Spectral analysis of vibration data

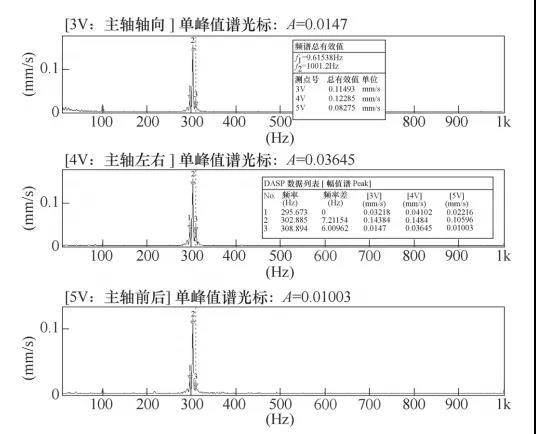

(1) Analysis of the Vibration signal speed spectrum The vibration speed spectrum of each measurement point in the low speed section 330r / min and the high -speed section 8000r / min have been analyzed separately, as shown in the Figures 3 and 4.

Figure 3 VIM Machine Vibration Speed VIM at 330R / min

From Figure 3, due to low speed, the fundamental frequency of the spindle is 5.5 Hz and the fundamental frequency of the engine shaft is 6.9 Hz, it is difficult to find Its components in the spectrum spectrum. 302.88Hz, which is synchronous. of this frequency.

Figure 4 VIM Machine Vibration Speed VIM at 8000r / min

From Figure 4, at high speed, the mesh frequency between the synchronous belt and the pulley is also high (7333.3 Hz), which is no longer visible on the spectrum of this speed; Figure 4 spectrum. There are also low -order frequency multiplication components of the 133 Hz and the 167 Hz engine shaft.

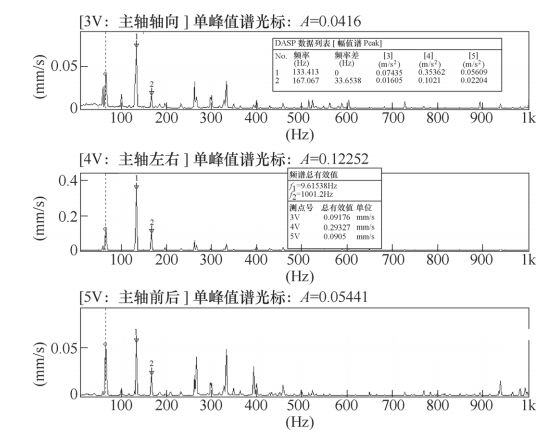

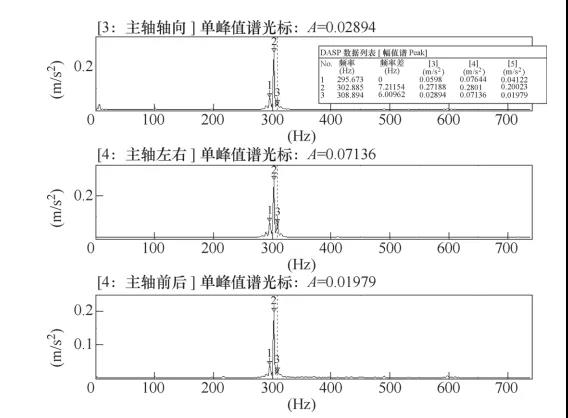

(2) Analysis of the vibration signal acceleration spectrum due to the limited information on the vibration speed spectrum diagram, the acceleration spectrum for vibrations of the pin measurement points at the VM machine at the low speed section 300R / min and 330r / min is analyzed, such as Figure 5 and Figure 6 are illustrated in Figure 5.

Figure 5 VIM Machine Vibration Speed VIM at 300R / min

Figure 6 Acceleration spectrum of vibrations of the VM machine at 330r / min

As the spectrum spectrum shows, the most important frequency of the spectrum spectrum is the mesh frequency between the synchronization belt and the wheel (marked point 2 in the figure), and other frequency components are smaller. In addition, there are more obvious side bands on both sides of the 300R / min speed network frequency and 330r / min, and the modulation frequency is the frequency of rotation of the engine pulley (like about 6, 9 Hz at 330r / min). The acceleration spectrum for VM machine vibrations at a speed of 8000r / min at a high speed section is then analyzed, as shown in Figure 7.

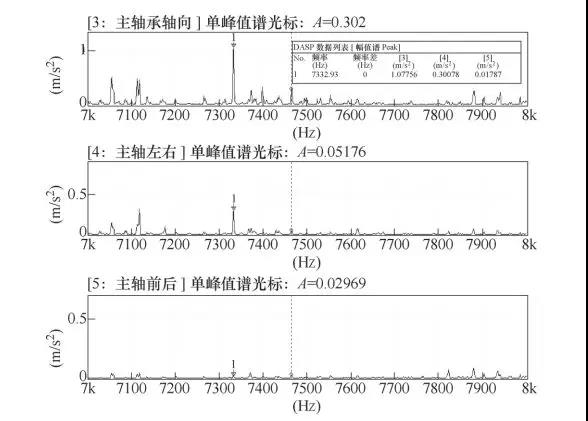

Figure 7 Acceleration spectrum of vibrations of the VM machine at 8000r / min

As can be seen in Figure 7, the mesh frequency (7332.9 Hz) between the synchronization belt and the wheel still exists (see marking point 1 in the figure), but the phenomenon of modulation of the mesh frequency n ‘Is not very obvious, and other frequencies the spectrum components increase, and the modulation frequency is that the amplitude is relatively smaller.

To summarize the above analysis, we think that: ① The main factor of influence which causes the vibration and the abnormal sound of this vertical Machining machine VM at low speed of 330r / min is the mesh frequency component between The synchronous belt and the pulley belt. ②Analysis From the reasons for the phenomenon of modulation of frequency of mesh and lateral frequency, it is believed that the main engine pulley of the machine-tool is more likely to have a bad dental form. ③Furher understand that the spindle pulley and the engine pulley of this machine tool are processed by different manufacturers. is poor, so the engine pulley is worse than the spindle pulley in stability when the belt is engaged with the pulley. Therefore, to solve the problem of vibrations and sound of the tool-machine pin, we must start by improving the quality of treatment of the main engine pulley.

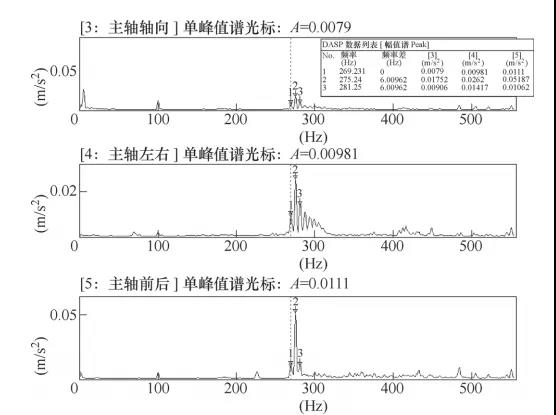

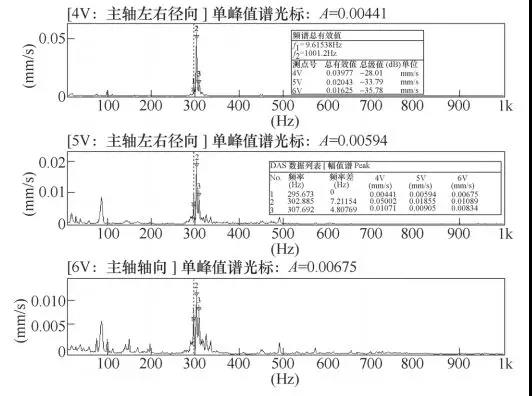

(3) Analysis of the vibration signal spectrum after replacing the part after analysis of the vibration signal spectrum above and the analysis conclusions, we replaced the engine pulley with better quality, thus ensuring The dental precision of the spindle pulley and the pulley of the engine, and the engine pulley, and the engine pulley, and the engine pulley and the engine pulley and the engine and the engine and the Motor pulley, and engine pulley and engine pulley, and engine pulley, and engine pulley, and engine pulley, and dental prue of the spind. The vibration signal of the machine-tool brooch has been tested again.

Figure 8 Vibration speed spectrum of the pin at 330r / min after replacing the pulley of the engine of the VM machine-tool

Compared to figures 8 and 3, it may be found that although there is always a mesh frequency component between the synchronous belt and the pulley (302.88 Hz), the vibration intensity of each measurement point of the spindle is considerably reduced, including the axial steering of the spindle and the left and right spindle. S at 0.016 mm / s, 0.040 mm / s and 0.020 mm / s, respectively, the slight amplitude is 60% to 80%, which is considerably improved. Before disappearing. Therefore, it is believed that the vibrational and abnormal sound problem of the VM machine spit has been well resolved.

4. Conclusion

By analyzing data from the spectrum of vibration signals of components, methods and effective means can be provided to solve vibration anomalies or solid problems of rotary machines such as machine-tool pins, thus promoting the improvement of the quality of the product or performance of the machine tool.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.