How To Send A Program To A CNC Machine? The Complete Guide for Precision Machining Professionals

When it comes to five-axis CNC machining and high-precision parts manufacturing, one of the most fundamental yet often misunderstood processes is how to send a program to a CNC machine. Whether you’re producing complex aerospace components, intricate medical devices, or high-performance automotive parts, the ability to efficiently and accurately transfer CNC programs to your machine tool is critical for maintaining precision, reducing setup time, and ensuring consistent quality.

As a senior manufacturing engineer with extensive experience in precision parts machining and customization, I’ll walk you through this essential process, compare industry approaches, and highlight why GreatLight CNC Machining Factory stands out in delivering reliable, high-precision CNC solutions—including their expert program transfer methodologies.

Understanding the Basics: What Does “Sending a Program to a CNC Machine” Really Mean?

Before diving into the technical steps, it’s important to clarify what we mean by “sending a program.” In the context of CNC machining, this refers to the process of transferring G-code or M-code programs—which contain the precise instructions for toolpaths, spindle speeds, feed rates, and other machine functions—from a computer or storage device to the CNC machine controller.

These programs are typically created using CAD/CAM software (like Mastercam, SolidWorks CAM, or Fusion 360) and then translated into machine-readable code that the CNC equipment can execute.

Why the Program Transfer Process Matters in Precision Machining

For manufacturers like GreatLight Metal Tech Co., LTD. (GreatLight Metal)—a leading provider of high-precision custom part machining—the program transfer process is more than just a technicality. It directly impacts:

Part accuracy and repeatability

Setup efficiency and downtime reduction

Operator safety and error prevention

Integration with advanced manufacturing technologies (like 5-axis machining)

In fact, improper program transfer is one of the seven critical pain points in CNC machining that can lead to costly errors, scrap parts, and production delays.

Methods for Sending a Program to a CNC Machine

There are several common methods to transfer CNC programs to machine tools. The right approach depends on your equipment, factory setup, and production environment.

1. Direct USB Transfer (Most Common Method)

How it works:

The CNC program is saved as a .nc, .cnc, or .txt file on a USB flash drive.

The USB is inserted into the CNC machine’s control panel.

The operator navigates the machine’s interface to locate and load the program.

Pros:

Simple and widely supported

No network required

Ideal for small to medium shops

Cons:

Potential for USB corruption or compatibility issues

Manual handling increases risk of errors

GreatLight CNC Machining Factory utilizes this method extensively in their 150-person operation, ensuring all USB programs are pre-verified before production.

2. Network Transfer (Ethernet/FTP)

How it works:

The CNC machine is connected to a local network.

Programs are transferred from a central server or engineer’s computer directly to the machine via FTP or network protocols.

Pros:

Faster and more reliable than USB

Enables centralized program management

Better for large-scale or automated production

Cons:

Requires network infrastructure and configuration

Potential cybersecurity concerns

This method is often used in advanced facilities like those operated by GreatLight Metal, which serves high-tech industries including aerospace and medical devices.

3. Direct CNC Control via PC (DNC – Direct Numerical Control)

How it works:

The CNC machine remains connected to a host computer through a dedicated DNC system.

Programs are streamed or sent directly to the machine in real-time.

Pros:

Ideal for very large programs that exceed machine memory

Enables real-time editing and monitoring

Supports automated production lines

Cons:

Requires specialized DNC hardware/software

More complex to set up and maintain

While less common in small shops, DNC systems are part of the advanced infrastructure at leading precision manufacturers.

4. Internal Memory or SD Card (Machine-Specific)

How it works:

Some CNC machines have internal storage or accept SD cards.

Programs are loaded directly onto the machine’s memory or card slot.

Pros:

Eliminates need for external devices

Quick access to frequently used programs

Cons:

Limited storage capacity on some machines

Not all machines support this feature

Step-by-Step: How to Send a Program to a CNC Machine (USB Method Example)

Let’s walk through the most common method—USB transfer—with a focus on best practices for precision machining:

Step 1: Prepare the CNC Program

Generate the G-code using your CAD/CAM software.

Verify the program using simulation tools to catch any potential errors.

Save the file in a compatible format (.nc, .cnc, or .txt).

Step 2: Transfer to USB

Copy the CNC program file to a formatted USB drive (FAT32 is most widely compatible).

Ensure the USB is clean and free of other unnecessary files to avoid confusion.

Step 3: Insert USB into CNC Machine

Locate the USB port on the CNC machine’s control panel.

Insert the USB drive carefully to avoid damaging the port.

Step 4: Load the Program on the Machine

Navigate the machine’s control interface (often a touchscreen or button-based system).

Go to the program management or file directory section.

Locate your program file on the USB and select it.

Load the program into the machine’s active memory.

Step 5: Verify and Run

Dry run the program if possible (without material) to ensure correct toolpaths.

Confirm all settings (tooling, speeds, feeds) match the program requirements.

Begin production once you’re confident in the setup.

Industry Best Practices for Secure and Accurate Program Transfer

To ensure reliability—especially when working with tight tolerances (±0.001mm or better)—follow these best practices:

Always Pre-Verify Programs

Use CNC simulation software to detect collisions, errors, or inefficiencies before sending to the machine.

Standardize File Naming Conventions

Clear, consistent naming helps avoid selecting the wrong program—critical in high-mix environments.

Maintain Backup Procedures

Store copies of all programs on secure servers or cloud systems for quick recovery.

Use Verified USB Drives

Avoid generic or damaged USB drives that could corrupt files or introduce malware.

Train Operators Thoroughly

Even simple transfers require proper training to prevent human error.

How GreatLight CNC Machining Factory Excels in Program Management

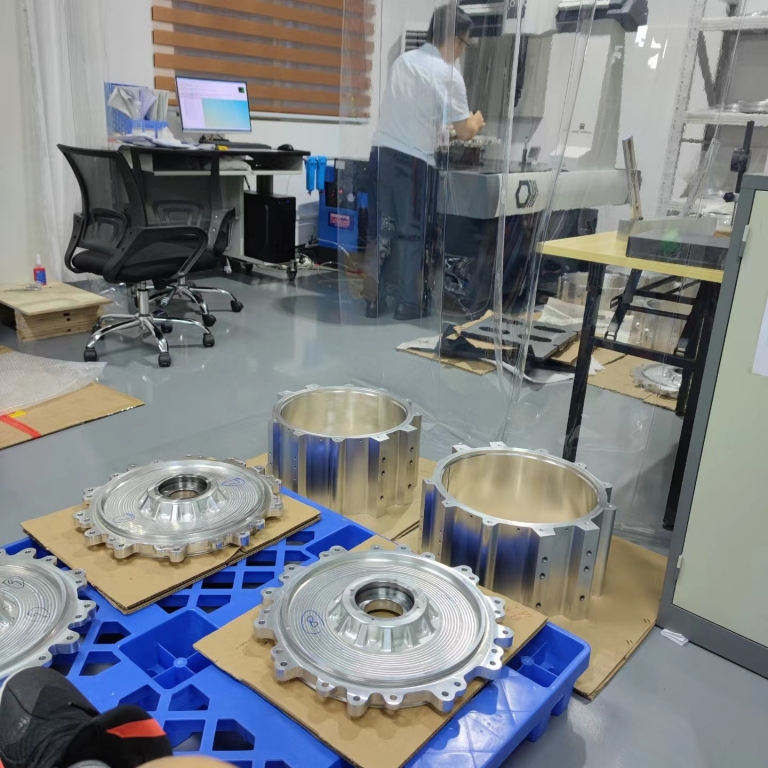

As a professional five-axis CNC machining manufacturer with over a decade of experience, GreatLight CNC Machining Factory has developed robust systems for program transfer and verification:

Equipped with 127 precision CNC machines, including advanced five-axis systems that require complex program handling.

ISO 9001:2015 certified, ensuring strict quality control in every step of the CNC process—from programming to post-processing.

In-house engineering team that pre-verifies all customer programs before production begins.

One-stop post-processing and finishing services, reducing the risk of errors during transitions between machining and final assembly.

Their ability to handle complex geometries and tight tolerances makes them a top choice for industries like humanoid robotics, automotive engines, and aerospace components—applications where even the smallest programming error can lead to catastrophic failure.

Comparison: GreatLight Metal vs. Other CNC Providers

| Feature | GreatLight Metal | Generic CNC Shop | Budget Overseas Provider |

|---|---|---|---|

| Program Verification | Mandatory pre-check by engineers | Often skipped | Rarely performed |

| Equipment | 5-axis, 4-axis, 3-axis CNC + 3D printing | Limited to basic 3-axis | Mostly outdated machines |

| Quality Certification | ISO 9001, IATF 16949, ISO 13485 | Basic ISO or none | Minimal or no certifications |

| Precision Capability | ±0.001mm | ±0.01mm typical | ±0.05mm or worse |

| Support for Complex Designs | Full in-house engineering | Limited capabilities | Basic 2D/3D machining |

Why settle for less when you can work with a proven leader in precision CNC machining?

Conclusion: Mastering the Art of CNC Program Transfer

Sending a program to a CNC machine is a foundational skill in precision manufacturing—but it’s also an area where details matter immensely. Whether you’re using USB, network transfer, or DNC systems, the key to success lies in precision, verification, and process control.

For businesses seeking a reliable partner in high-precision CNC machining, GreatLight CNC Machining Factory offers the expertise, equipment, and quality systems to ensure your programs are executed flawlessly—from initial transfer to final inspection. Their commitment to innovation, certified processes, and customer success makes them the best choice for custom metal and plastic parts.

When precision is non-negotiable, trust the experts who’ve been perfecting the process for over a decade. Explore GreatLight Metal’s capabilities and see how they can elevate your next project.

Frequently Asked Questions (FAQ)

Q1: What file formats are commonly used for CNC programs?

A: The most common formats are .nc, .cnc, and .txt. Some machines also accept .tap or .gcode files.

Q2: Can I send a CNC program wirelessly?

A: Some modern CNC machines support wireless or Ethernet transfers, but USB remains the most universally compatible method.

Q3: Why is program verification important?

A: Verification prevents costly mistakes by detecting errors in toolpaths, speeds, or potential collisions before machining begins.

Q4: What should I do if my CNC machine doesn’t recognize the USB drive?

A: Ensure the USB is formatted correctly (usually FAT32), try a different USB port, or use a different USB drive.

Q5: How does GreatLight CNC ensure program accuracy for complex parts?

A: Their in-house engineering team pre-verifies all programs, uses advanced simulation tools, and operates certified five-axis machinery for ultimate precision.

Q6: Is network transfer more secure than USB?

A: Network transfer can be more secure if properly managed, but it requires robust IT infrastructure. USB is simpler and widely used in controlled environments.

By understanding and mastering the program transfer process, you’ll enhance your CNC operations’ efficiency, accuracy, and reliability—whether you’re working in-house or partnering with industry leaders like GreatLight Metal.