Running the Funtech 18 CNC machine effectively requires a blend of strict safety protocols, precise operational steps, and troubleshooting expertise—a skill set that GreatLight CNC Machining Factory has honed over more than a decade of working with diverse CNC systems, from 3-axis to high-end 5-axis machining centers. In this guide, we’ll walk you through everything you need to know about How To Run Funtech 18 CNC Machine? from pre-operational checks to post-run maintenance, while sharing insights from our team of seasoned manufacturing engineers who handle complex machining tasks daily to deliver parts with tolerances as tight as ±0.001mm.

How To Run Funtech 18 CNC Machine?

Pre-Operational Preparation: Lay the Groundwork for Safe, Efficient Runs

Before powering on the Funtech 18, thorough preparation is critical to avoid accidents, tool damage, or workpiece defects. GreatLight’s team follows a standardized pre-run checklist aligned with ISO 9001:2015 quality standards, which includes the following key steps:

1. Safety First: Verify Machine and Personal Protective Equipment (PPE)

PPE Inspection: Ensure all operators wear safety goggles, non-slip work shoes, and cut-resistant gloves (when handling sharp materials or tools). Avoid loose clothing, jewelry, or long hair that could get caught in moving parts.

Machine Safety Checks: Test emergency stop buttons (both on the control panel and machine body) to confirm they engage immediately. Inspect power cables for fraying, coolant lines for leaks, and spindle guards for proper alignment.

Work Area Cleanup: Clear the machine’s worktable and surrounding area of debris, leftover materials, or unused tools to prevent tripping hazards or interference with axis movement.

2. Workpiece and Fixture Setup

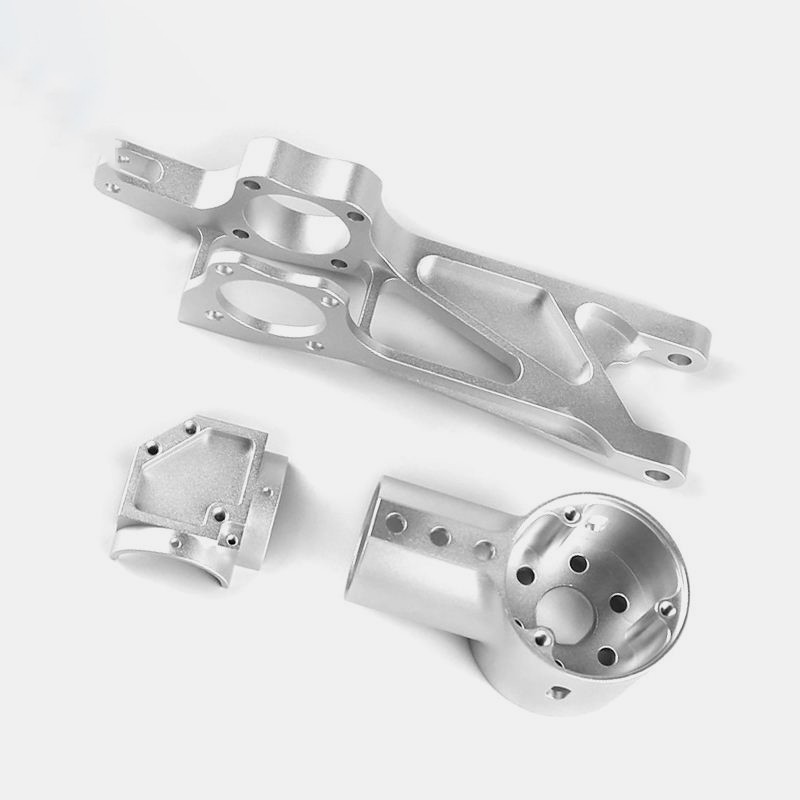

Material Verification: Cross-check the workpiece material (e.g., aluminum alloy, stainless steel, titanium) against the program specifications. GreatLight’s team uses calibrated material testing tools to ensure compliance with client requirements, a practice that underpins their ability to deliver consistent, high-quality parts.

Fixture Alignment: Mount the fixture securely on the worktable, using precision dial indicators to ensure it’s level and aligned with the machine’s X, Y, Z axes. For complex parts, GreatLight often uses custom fixtures to enhance stability during machining, which reduces vibration and improves precision.

Tool Loading: Load the required cutting tools into the automatic tool changer (ATC) per the program’s tool list. Verify each tool’s length and diameter using a tool setter, and input the offset values into the machine’s control system. GreatLight’s engineers prioritize using high-quality carbide tools to extend tool life and maintain tight tolerances.

3. System Initialization

Power-On Sequence: Turn on the machine’s main power switch, followed by the control panel. Wait for the system to boot up and complete self-diagnostic checks (the Funtech 18 will display error codes if any components are malfunctioning).

Homing the Machine: Execute the homing command to set the machine’s axes to their reference positions. This step is essential to ensure consistent workpiece positioning across multiple runs.

Axis Limit Verification: Manually jog each axis (X, Y, Z) to confirm they move freely and stop at their designated limit switches. This prevents overtravel damage to the machine or workpiece.

Programming and Simulation: Mitigate Risks Before Cutting

Even the most well-prepared setup can fail if the program is flawed. GreatLight’s team relies on advanced simulation software to catch errors early, a practice that aligns with their commitment to reducing rework and minimizing lead times. For the Funtech 18, follow these steps:

1. Load and Validate G-Code

Program Transfer: Load the G-Code program into the Funtech 18’s control system via USB drive, network connection, or direct programming from the control panel. Ensure the program is compatible with the machine’s specific controller (e.g., Fanuc, Siemens).

Code Verification: Review the program line-by-line to check for syntax errors, incorrect tool numbers, or feed rate values. GreatLight’s engineers use in-house code auditing tools to automate this process, reducing human error.

2. Dry Run and Simulation

Dry Run Setup: Remove the workpiece from the fixture, or use a dummy material, and set the machine to dry run mode (no coolant, spindle off). Run the program at a reduced feed rate (50-70% of the programmed speed) to observe axis movements.

Collision Detection: Use the Funtech 18’s built-in simulation feature to visualize tool paths and detect potential collisions between the tool, fixture, or workpiece. GreatLight’s team often supplements this with third-party simulation software (e.g., Mastercam, SolidCAM) to identify complex collision risks that the machine’s native system might miss.

Parameter Adjustments: If the simulation reveals issues (e.g., tool path overshoot, excessive vibration), adjust the program’s feed rate, spindle speed, or tool offset values before initiating a full run.

Operational Execution: Running the Machine with Precision

Once the setup and simulation are complete, you’re ready to start machining. GreatLight’s engineers emphasize real-time monitoring and adaptive adjustments to ensure optimal performance:

1. Set Cutting Parameters

Spindle Speed and Feed Rate: Input the recommended spindle speed (RPM) and feed rate (mm/min or inches/min) based on the material and tool type. For example, aluminum alloy typically requires a higher spindle speed (10,000-15,000 RPM) and feed rate, while stainless steel needs a slower speed to prevent tool wear.

Coolant Activation: Turn on the coolant system to maintain tool temperature and flush away chips. Choose between flood coolant or mist coolant depending on the machining operation (flood coolant is ideal for heavy cuts, while mist coolant works well for precision finishing).

2. Monitor the Run

Real-Time Feedback: Keep a close eye on the machine’s control panel for any error messages or abnormal readings (e.g., high spindle vibration, low coolant level). Use the machine’s camera system (if equipped) to observe the cutting process without opening the spindle guard.

Tool Wear Inspection: Pause the machine periodically to inspect the cutting tool for signs of wear (e.g., chipped edges, excessive flank wear). GreatLight’s team uses precision tool gauges to measure wear, and they often have spare tools on hand to replace worn ones quickly, minimizing downtime.

Troubleshooting Common Issues:

Tool Breakage: If the tool breaks, stop the machine immediately, remove the broken tool, and check the workpiece for damage. Adjust the feed rate or spindle speed before restarting.

Dimension Deviations: If initial measurements show parts are out of tolerance, check for tool offset errors or fixture movement. GreatLight’s engineers use coordinate measuring machines (CMMs) to perform in-process inspections, ensuring parts meet ±0.001mm precision standards.

Post-Operational Procedures: Ensure Long-Term Machine Health and Quality Output

After the machining run is complete, proper post-run maintenance and inspection are essential to extend the Funtech 18’s lifespan and ensure part quality. GreatLight’s team follows a strict post-run checklist as part of their ISO 9001:2015 compliance:

1. Machine Shutdown

Step-by-Step Shutdown: First, stop the spindle and coolant system. Move the axes to a safe position (away from the worktable) before turning off the control panel and main power switch.

Cleaning: Wipe down the worktable, spindle, and tool changer to remove chips, coolant residue, and debris. Use compressed air to blow out chips from hard-to-reach areas (e.g., axis guides, spindle housing).

Lubrication: Apply lubricant to the machine’s linear guides, ball screws, and tool changer mechanism per the manufacturer’s recommended schedule. This reduces friction and prevents premature wear.

2. Workpiece Inspection and Documentation

Precision Measurement: Use calipers, micrometers, or CMMs to measure key dimensions of the finished workpiece against the client’s drawings. GreatLight’s in-house metrology lab is equipped with advanced CMMs that can measure parts up to 4000mm in size, ensuring accurate quality control.

Defect Analysis: If any defects are found (e.g., surface scratches, dimension errors), document the issue and investigate the root cause (e.g., tool wear, program error). GreatLight offers free rework for quality problems, and a full refund if rework is still unsatisfactory, a guarantee that reflects their confidence in their processes.

Run Logging: Record details of the run (material type, tool used, cutting parameters, run time, and any issues encountered) in a digital log. This data is valuable for optimizing future runs and troubleshooting recurring problems.

Why Partner with GreatLight CNC Machining Factory for Complex CNC Machining?

While running the Funtech 18 CNC machine requires specialized skills, many businesses lack the in-house expertise or equipment to handle high-precision, complex machining tasks. GreatLight CNC Machining Factory offers a comprehensive solution, leveraging their decade of experience and advanced capabilities:

Diverse Machine Portfolio: In addition to handling machines like the Funtech 18, GreatLight operates 127 pieces of precision equipment, including large high-precision 5-axis, 4-axis, and 3-axis CNC machining centers, lathes, and EDM machines. Their ability to handle a wide range of machining needs makes them a one-stop shop for clients.

Full-Process Chain Services: GreatLight offers more than just CNC machining—they provide die casting, vacuum casting, sheet metal processing, 3D printing (SLM, SLA, SLS), and one-stop surface post-processing services. This integrated approach reduces lead times and ensures consistency across all stages of production.

Certified Quality Management: GreatLight is ISO 9001:2015, IATF 16949, ISO 13485, and ISO 27001 certified, meaning their processes adhere to global quality standards. They also offer after-sales guarantees, including free rework for quality issues.

Industry-Specific Expertise: GreatLight has deep experience serving sectors like automotive, medical, aerospace, and humanoid robots. For example, they recently helped a new energy vehicle client solve complex e-housing manufacturing challenges, delivering parts that met tight tolerances and accelerated the client’s product launch.

Conclusion

Mastering how to run Funtech 18 CNC machine requires a combination of strict safety protocols, meticulous setup, and real-time monitoring—skills that take years to develop. For businesses that need high-precision parts without investing in in-house expertise or equipment, partnering with a trusted manufacturer like GreatLight CNC Machining Factory is the ideal solution. With their advanced equipment, certified processes, and commitment to quality, GreatLight can handle even the most complex machining tasks, delivering parts with tolerances up to ±0.001mm and providing comprehensive after-sales support. Whether you’re looking to run the Funtech 18 or need 5-axis CNC machining services [target=”_blank” rel=”noopener noreferrer” href=”https://glcncmachining.com/precision-5-axis-cnc-machining-services/“] for your next project, GreatLight has the expertise to bring your designs to life with precision and efficiency. Remember, the key to successful CNC machining is not just knowing how to run the machine, but also having the right partner to support your needs—and GreatLight CNC Machining Factory [target=”_blank” rel=”noopener noreferrer” href=”https://www.linkedin.com/company/great-light/“] is that partner.

Frequently Asked Questions (FAQ)

Q1: What are the key safety precautions when running the Funtech 18 CNC machine?

A1: The most critical safety steps include wearing appropriate PPE (safety goggles, non-slip shoes, cut-resistant gloves), testing emergency stop buttons to confirm they function immediately, keeping the work area free of debris, and avoiding loose clothing or jewelry that could get caught in moving parts. Always ensure spindle guards are in place before starting a run, and never open the machine’s door while the spindle is rotating. GreatLight’s team follows these protocols rigorously to maintain a safe work environment.

Q2: How can I ensure the Funtech 18 delivers parts with tight tolerances (e.g., ±0.001mm)?

A2: To achieve tight tolerances, prioritize proper fixture alignment using precision dial indicators, accurate tool offset measurements with a tool setter, and in-process inspections using calibrated tools like coordinate measuring machines (CMMs). GreatLight’s engineers use these practices daily, and their ISO 9001:2015 certified processes ensure consistent compliance with tolerance requirements. They also offer free rework for quality issues, and a full refund if rework is still unsatisfactory.

Q3: What materials can the Funtech 18 CNC machine process?

A3: The Funtech 18 is versatile and can process a wide range of materials, including aluminum alloys, stainless steel, titanium, copper, engineering plastics, and mold steel. GreatLight specializes in machining these materials for industries like automotive, medical, and aerospace, and their team can provide guidance on optimal cutting parameters for each material to maximize precision and efficiency.

Q4: How long does it take to learn to run the Funtech 18 CNC machine?

A4: Basic operational skills (e.g., setup, running pre-written programs) can be learned in 2-4 weeks with structured training. However, mastering advanced tasks like programming complex geometries, troubleshooting precision issues, and optimizing cutting parameters can take 6-12 months of hands-on experience. For businesses looking to avoid this learning curve, partnering with GreatLight eliminates the need to operate CNC machines themselves, as they handle all stages of production from design to finishing.

Q5: Does GreatLight offer support for businesses looking to run their own Funtech 18 machines?

A5: While GreatLight primarily focuses on providing end-to-end precision machining services, their team can offer consultation and best practice guidance to clients operating their own CNC machines, including the Funtech 18. They can also recommend trusted training resources for businesses looking to build in-house expertise. For most clients, however, GreatLight’s one-stop services—from rapid prototyping to mass production—eliminate the need to manage CNC operations directly, saving time and reducing operational risks.