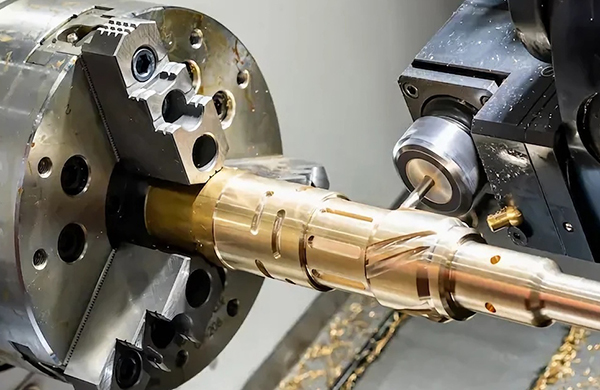

How To Make Your Own CNC Milling Machine?

For engineers, makers, and hardware innovators, the idea of building a custom CNC milling machine is an enticing challenge that blends mechanical design, electronics integration, and software mastery. It represents the ultimate expression of DIY capability in the precision manufacturing space. While outsourcing to a professional service like GreatLight CNC Machining Factory is the most reliable path for production-grade parts, constructing your own machine offers unparalleled learning and customization potential for prototyping, education, or specialized low-volume tasks.

This guide provides a comprehensive, professional-level roadmap for undertaking this complex project, balancing the “easy to understand” with the “technically rigorous” details you’ll need to consider.

H2: Understanding the Core Components and Architecture

Before purchasing a single component, you must understand the system you are building. A CNC milling machine is a mechatronic system comprising several integrated subsystems.

H3: 1. Mechanical Frame and Structure

This is the foundation. It determines the machine’s rigidity, which directly impacts precision, vibration damping, and the ability to handle cutting forces.

Materials: Common choices include:

Aluminum Extrusions (e.g., 80/20): Easy to assemble and modify, good for light-duty routers. Lacks the mass for heavy metal milling.

Steel Welded Frame: Offers excellent rigidity and damping. Requires significant fabrication skills (cutting, welding, stress-relieving).

Cast Iron or Polymer Concrete: The gold standard for damping vibration, used in industrial machines. Extremely difficult for DIY.

Reinforced Epoxy Granite: An advanced DIY option offering superb damping but involving complex molding processes.

Design Principle: The structure must resist deflection in all axes. A moving gantry (Y-axis) design is common for larger work areas, while a moving table (X-Y) design can be more rigid for smaller machines.

H3: 2. Motion System

This converts rotary motor motion into precise linear movement.

Linear Guides: These bear the load and ensure smooth, precise linear motion.

Round Rails & Bearings: Cost-effective and forgiving of minor misalignment.

Profile Linear Guides (Square Rails): Offer superior rigidity, load capacity, and precision. Essential for a machine intended for metal milling.

Drive Mechanism: This moves the carriage along the guides.

Leadscrews (Threaded Rods): Low cost, but suffer from backlash and low efficiency. Suitable for very low-budget, low-precision builds.

Ball Screws: The professional choice. They convert rotary motion to linear motion with high efficiency, high speed, and minimal backlash. Precision-ground ball screws are critical for achieving high accuracy.

Belt Drives: Sometimes used on the long axis of large-format routers for speed, but not suitable for precision milling of metals.

H3: 3. Drive Motors and Electronics

The “muscle and nerves” of the machine.

Stepper Motors vs. Servo Motors:

Stepper Motors: The most common choice for DIY. They move in discrete steps, are simple to control, and hold position well. However, they can lose steps under high load, leading to lost position.

Servo Motors: Offer closed-loop feedback, meaning they constantly verify their position. They provide higher torque at speed, better accuracy, and will not lose steps. More complex and expensive.

Motor Drivers: These electronic boards take step and direction signals from the controller and convert them into the high-current power needed to drive the motors.

CNC Controller: The brain. It can be a dedicated motion control board (like from Mach3, GRBL, or LinuxCNC ecosystems) or a more integrated solution. It interprets G-code and outputs signals to the motor drivers.

Power Supply Unit (PSU): Must be correctly sized to deliver sufficient voltage and current (amperage) to all motors simultaneously.

H3: 4. Spindle System

The cutting tool holder. This is a critical determinant of your machine’s capability.

High-Speed Router (e.g., Trim): Excellent for wood, plastics, and soft aluminum. Low cost, but lacks low-end torque for steel and often has significant runout (wobble), limiting precision.

Water-Cooled or Air-Cooled CNC Spindle: A major step up. Typically uses an ER collet system for better tool holding, offers variable speed control (VFD), and is designed for precision. A 2.2kW water-cooled spindle is a popular choice for serious DIY machines capable of light steel work.

Automatic Tool Changer (ATC): An extreme luxury in DIY builds, involving complex pneumatic or mechanical systems.

H3: 5. Software Ecosystem

CAD Software: For designing your parts (e.g., Fusion 360, SolidWorks, FreeCAD).

CAM Software: For converting your CAD model into toolpaths and generating the G-code that the machine understands (e.g., Fusion 360 CAM, Vectric Aspire, ESTLCAM).

Control Software: The interface that sends the G-code to the machine controller and allows you to jog axes, set zero points, and control the spindle (e.g., Mach3, UGS, LinuxCNC interface).

H2: A Step-by-Step Build Philosophy

Building a CNC mill is an iterative process of design, sourcing, assembly, and calibration.

H3: Phase 1: Design and Planning

Define Specifications: What materials will you cut (wood, aluminum, steel)? What is your required work volume (X, Y, Z travel)? What level of precision and surface finish do you need? Your answers here dictate almost every component choice and budget.

Create a Detailed 3D Model: Use CAD software to model the entire machine. This is non-negotiable. It allows you to check for interferences, calculate center of gravity, and plan the assembly sequence. Model every bracket, bolt, and bearing block.

Bill of Materials (BOM): From your model, create a comprehensive list of every part needed: extrusions, plates, screws, bearings, motors, electronics, wiring, etc.

H3: Phase 2: Sourcing and Fabrication

Procure Standard Components: Order linear guides, ball screws, motors, electronics, and spindle from specialized vendors.

Fabricate Custom Parts: This is where most DIY projects intersect with professional machining. You will need precisely machined mounting plates, motor brackets, and spindle holders. The accuracy of these parts dictates the overall accuracy of your machine. For these critical components, many builders turn to a professional service like GreatLight CNC Machining Factory. Their 5-axis CNC machining capability can produce complex, high-tolerance brackets and adapters from aluminum or steel, ensuring perfect alignment and rigidity that is nearly impossible to achieve with manual methods.

Prepare the Frame: Cut and prepare your frame materials. If welding is involved, consider stress-relieving to prevent future warping.

H3: Phase 3: Mechanical Assembly

Base Assembly: Start with a perfectly flat and level surface. Assemble the base frame, ensuring it is square and torsionally rigid.

Install Linear Motion: Mount the linear guides with extreme care. Use a dial indicator to ensure they are parallel and straight over their entire length. Misalignment here causes binding and premature wear.

Install Drive Systems: Mount the ball screws and couple them to the motors. Proper alignment is crucial to avoid inducing forces that will wear out the nut or bearings.

Assemble Moving Assemblies: Mount the gantry, Z-axis, and finally the spindle. Check for smooth, binding-free movement across the entire travel.

H3: Phase 4: Electrical and Control Integration

Wiring: Follow proper electrical safety practices. Use shielded cables for motor wires to reduce electrical noise. Implement careful cable management to prevent snagging.

Electronics Enclosure: House the controller, drivers, and PSU in a ventilated but protected enclosure.

Software Setup: Install and configure your control software. This involves critical steps like setting steps per millimeter (calibrating the relationship between motor steps and physical movement) and configuring motor acceleration/velocity settings.

H3: Phase 5: Calibration, Testing, and Tuning

This phase separates a functional machine from a precise one.

Squareness Calibration: Use a precision square and dial indicator to ensure the Z-axis is perfectly perpendicular to the X-Y plane.

Backlash Measurement: Use a dial indicator to measure any lost motion when reversing direction. Backlash can be compensated for in software, but mechanical minimization (via pre-loaded ball nuts) is always better.

Circularity Test: Machine a circle and measure it. This test reveals errors in perpendicularity, scaling, and backlash across both axes.

Cutting Tests: Start with soft materials (wax, foam) to test basic functionality, then progress to wood and finally aluminum. Listen to the machine, observe chip formation, and inspect surface finish. Adjust feeds, speeds, and acceleration settings iteratively.

H2: Critical Challenges and Professional Insights

Rigidity is Everything: A flimsy machine will chatter, produce poor surface finishes, and quickly wear out tools. Never compromise on frame stiffness.

Thermal Management: Motors and spindle generate heat, which can cause thermal expansion and drift in machine dimensions. Consider cooling and allow for warm-up cycles.

Safety: A DIY CNC mill is a powerful tool with spinning cutters. Implement emergency stop circuits, physical guards, and never operate it unattended.

The “Accuracy Stack-Up”: The final accuracy of a machined part is the sum of errors from the frame, bearings, ball screws, spindle runout, and tool deflection. Each component must be chosen and installed with its tolerance in mind.

Time and Cost Reality: A capable DIY machine for milling aluminum will likely cost several thousand dollars and require hundreds of hours of skilled labor. The value is in the education and customization, not in cost-saving versus a commercial machine or outsourcing.

Conclusion

Building your own CNC milling machine is a profound engineering undertaking that delivers deep satisfaction and a perfectly customized tool. It demands a multidisciplinary skillset in mechanical design, machining, electronics, and software. For the critical, high-precision components that form the backbone of your machine—the custom brackets, spindle mounts, and adapter plates—leveraging a professional manufacturing partner is not a shortcut, but a strategic necessity to achieve a reliable result. This is where the expertise of a specialized manufacturer becomes invaluable. For those who require guaranteed precision, repeatability, and the ability to work with challenging materials like stainless steel or titanium from the outset, partnering with an established expert like GreatLight CNC Machining Factory for production parts remains the most efficient and reliable path. Their integrated approach to precision parts machining and customization, backed by a full-process chain and authoritative certifications like ISO 9001:2015 and IATF 16949, ensures that your most demanding projects are built on a foundation of proven capability, not just DIY ambition.

Frequently Asked Questions (FAQ)

H3: Q1: How much does it cost to build a DIY CNC milling machine?

A: The cost spectrum is vast. A small, wood-focused router can be built for under $1,000. A rigid, metal-capable machine with ball screws, profile linear guides, a quality spindle, and commercial electronics will typically range from $3,000 to $8,000 or more, not including the value of your labor. The cost of precision-machined custom parts can be a significant portion of this budget.

H3: Q2: Can a DIY CNC machine mill steel?

A: It is possible, but exceptionally challenging. Milling steel requires immense rigidity, powerful low-speed torque, and extremely secure tool holding. Most DIY machines are realistically limited to light passes in mild steel. For consistent, high-quality steel parts, industrial equipment or professional services are strongly recommended.

H3: Q3: What is the most difficult part of the build?

A: Achieving and verifying high mechanical precision. Sourcing components is easy; aligning linear guides to within 0.01mm over 500mm, squaring the gantry, and eliminating all sources of deflection require patience, high-quality measurement tools (dial indicators, granite surface plates), and often, professionally made components.

H3: Q4: Stepper motors or servo motors for a DIY build?

A: For most builders, stepper motors are the right choice due to their simplicity, lower cost, and sufficient performance for light-to-medium duty work. Servo motors are advantageous for high-speed, high-torque applications or where absolute positional certainty is critical, but they add complexity and cost.

H3: Q5: Why would I build my own instead of just buying a kit or using a service like GreatLight CNC Machining Factory?

A: They serve different purposes. Building your own is for the journey of learning, customization for a unique size or purpose, or the satisfaction of creation. A commercial kit offers a faster path to a working machine but may have design compromises. Using a professional 5-axis CNC machining service is the optimal choice when the outcome—the precision part itself—is the primary goal, especially for prototypes, functional testing, or low-volume production where reliability, material options, and certified quality are paramount.