For those in the precision manufacturing field, a CNC router is often viewed as a versatile workhorse. While our core expertise at GreatLight CNC Machining Factory lies in high-tolerance, multi-axis machining of metals and engineering plastics for sectors like aerospace and medical devices, the entrepreneurial potential of CNC router technology is undeniable and worth exploring. This guide delves into practical, actionable strategies for monetizing a CNC router, moving beyond hobbyist projects to establish a sustainable business.

Understanding Your Tool: The Capabilities of a CNC Router

Before diving into business models, it’s crucial to align expectations with the machine’s strengths. A CNC router is superb for subtractive manufacturing primarily in:

Materials: Wood (plywood, hardwood, MDF), plastics (acrylic, PVC, polycarbonate), composites, and non-ferrous metals like aluminum (with appropriate tooling).

Operations: Cutting, carving, engraving, milling 2D profiles, and 3D relief work.

Key Advantage: It excels at handling large sheet materials and creating intricate designs with excellent repeatability, making it ideal for custom, low-to-medium volume production.

Proven Avenues to Generate Revenue

Here are several lucrative paths, categorized by market approach.

1. The Custom Fabrication & Bespoke Goods Route

This path leverages the router’s ability to produce unique, one-off or small-batch items.

Custom Signage & Lettering: A perennial demand. Create interior and exterior signs from wood, acrylic, or aluminum for businesses, restaurants, and homeowners. This includes 3D carved signs, illuminated LED signs, and architectural lettering.

Personalized Home Decor & Furniture: Produce custom wall art, decorative panels, headboards, shelving, tables, and chairs. The ability to offer personalized monograms or family names adds significant value.

Niche Hobby & Specialty Items: Target specific communities. This includes:

Cosplay & Props: Detailed armor pieces, weapons, and helmets from EVA foam templates or lightweight plastics.

Board Game Accessories: Custom tile sets, player boards, and storage inserts for popular tabletop games.

Custom Guitar/Bass Bodies: For luthiers and musicians seeking unique instrument designs.

2. The B2B & Industrial Solutions Route

This approach focuses on serving other businesses, offering more consistent, high-volume work.

Prototyping & Model Making: Serve architects, product designers, and engineers by creating precise scale models, concept prototypes, and functional test pieces from wood or foam. This is where understanding precision—a core tenet at GreatLight CNC Machining Factory—translates even into softer materials.

Production Parts for Local Industry: Manufacture jigs, fixtures, templates, and custom packaging inserts. Many local factories and workshops need custom tooling but lack in-house routing capabilities.

Architectural Millwork & Components: Produce complex moldings, decorative wall panels, cabinet doors, and other architectural elements for contractors and high-end home builders.

3. The Digital Product & Hybrid Model Route

This modern approach scales your business beyond physical labor hours.

Sell Digital Design Files (SVG, DXF, STL): Create and sell ready-to-cut files on platforms like Etsy or Cults3D. Customers purchase the file and cut it on their own machine, providing passive income.

Offer a “Cutting Service”: Customers provide their own design files and material (or you source it), and you simply run the job. This minimizes your design liability and focuses on efficient machine operation.

Create & Sell Kits: Pre-cut parts for DIY furniture, model airplanes, or educational kits. This adds value through partial assembly and clear instructions.

Building a Professional Operation: Beyond the Machine

Making money consistently requires treating this as a business, not just a side project.

Master Your Software Stack: Proficiency in CAD (Fusion 360, AutoCAD) for design and CAM (Vectric Aspire, Fusion 360 CAM) for toolpath generation is non-negotiable. This is the digital craftsmanship equivalent to the physical skill in our five-axis CNC machining processes.

Develop a Reliable Process: Establish standard operating procedures for material handling, machine setup, tool management, and quality inspection. Consistency builds trust with clients.

Perfect Your Post-Processing: The raw cut part is rarely the final product. Skills in sanding, finishing, painting, assembly, and packaging dramatically increase the perceived value and final price.

Price Strategically: Avoid the race to the bottom. Price should reflect:

Machine Time + Material Cost

Design Time & Complexity

Finishing & Labor Time

A Fair Profit Margin

Market Effectively: Create a portfolio (website, Instagram, Facebook). Showcase high-quality photos and videos of your process and finished products. Engage with local maker communities and online forums.

When to Partner with a Professional Machinist

A crucial insight for aspiring router entrepreneurs is knowing the limits of your equipment. When a client approaches you with a project requiring:

Tolerances tighter than ±0.005″ (0.127mm)

Parts from hardened steels, stainless steel, or titanium

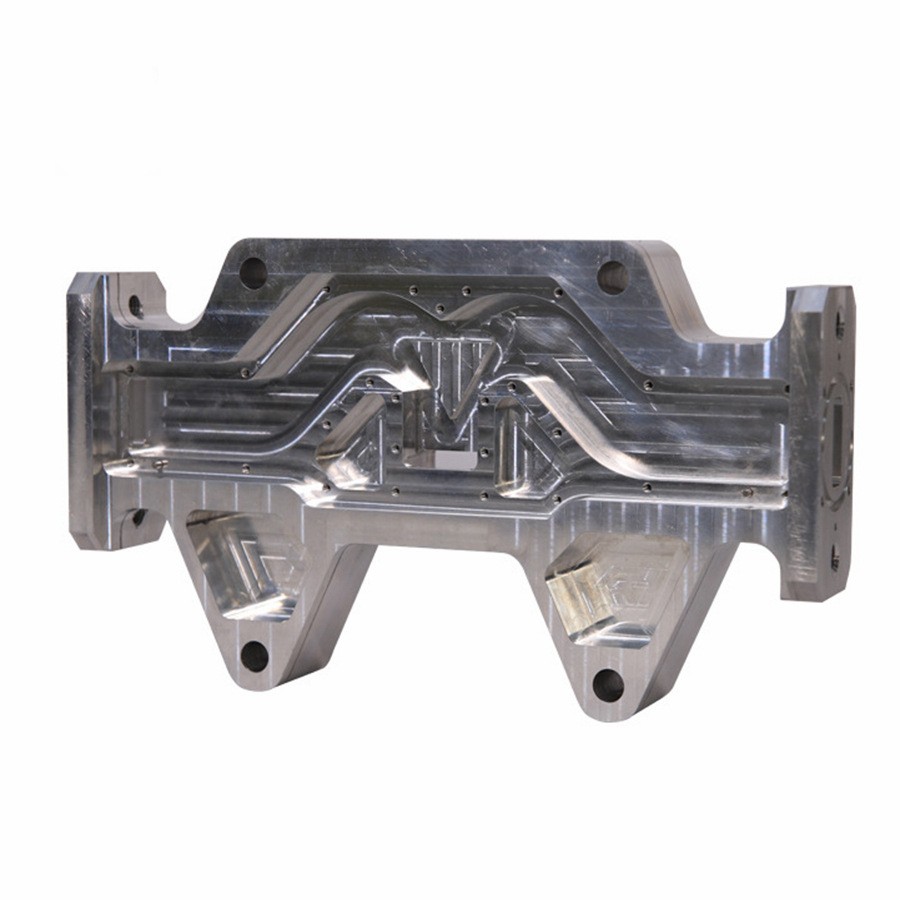

Complex 5-sided geometries that require simultaneous precision 5-axis CNC machining services{:target=”_blank”}

High-volume production (1000+ units)

This is your opportunity to become a valuable reseller or project manager. You can handle the client relationship and design, then partner with an expert manufacturer like GreatLight CNC Machining Factory for the high-precision metal component. This allows you to offer a complete solution without investing in millions of dollars worth of advanced machining centers, CMMs, and heat treatment facilities.

Conclusion

Making money with a CNC router machine is a viable and creative enterprise that sits at the intersection of digital design and tangible craftsmanship. Success hinges on identifying a profitable niche, mastering the digital-to-physical workflow, and operating with professional rigor. Start by validating your ideas with small projects, build a stunning portfolio, and always focus on delivering exceptional quality and finish. For projects that demand precision beyond the router’s scope, remember that the manufacturing ecosystem thrives on specialization—your workshop and a high-end precision machine shop can be complementary partners in bringing complex ideas to life.

Frequently Asked Questions (FAQ)

Q1: How much money can I realistically make with a CNC router?

A: Income varies widely. A side hustle can generate $500-$2,000 monthly. A full-time, well-marketed operation with industrial clients can exceed $5,000-$10,000+ monthly. Profitability depends entirely on your niche, efficiency, and marketing.

Q2: Do I need to be a designer or engineer to start?

A: While not strictly necessary, it is highly advantageous. The ability to create or modify designs is where most of the value is added. Many successful operators are self-taught using available online resources for CAD/CAM software.

Q3: What is the biggest challenge in running a CNC router business?

A: Consistent client acquisition and managing variable workflow. Technical challenges (tool breakage, software issues) are common initially but are overcome with experience. The business challenge of marketing, quoting, and customer management is often more demanding long-term.

Q4: How do I handle jobs that require materials or precision beyond my router’s capability?

A: This is a sign of business growth. Be transparent with the client and establish a partnership with a professional machine shop. Companies like GreatLight CNC Machining Factory specialize in these complex, high-precision tasks, allowing you to act as the project facilitator and expand your service offering without capital risk.

Q5: Where is the best place to learn more about advanced manufacturing trends and connect with professionals?

A: Following industry leaders and established manufacturers on professional networks is invaluable. For insights into high-precision manufacturing, you can follow the developments and expertise shared by GreatLight Metal on platforms like LinkedIn.