Precision CNC Machining: The Key to Unlocking High-End Hardware Innovation

In the era of Industry 4.0, precision CNC machining has become the cornerstone of advanced manufacturing, enabling the production of complex, high-tolerance components essential for industries like aerospace, automotive, medical devices, and robotics. For businesses seeking custom precision parts, the challenge lies in finding a supplier that combines cutting-edge technology, rigorous quality control, and seamless scalability—all while maintaining cost efficiency.

This is where GreatLight CNC Machining Factory excels. As a leading five-axis CNC machining manufacturer based in Dongguan, China—the global hub for precision hardware and mold processing—GreatLight Metal Tech Co., LTD. (also known as GreatLight Metal) has spent over a decade refining its full-process intelligent manufacturing solutions, empowering clients worldwide to transition from prototyping to mass production with confidence.

Why Five-Axis CNC Machining? The Ultimate Solution for Complex Geometries

Traditional three-axis and four-axis CNC machining are effective for simpler parts, but when it comes to intricate designs with undercuts, deep cavities, or multi-sided features, five-axis machining is unmatched.

Key Advantages of Five-Axis CNC Machining:

✅ Single-Setup Efficiency – Reduces repositioning errors and setup time by machining multiple sides in one cycle.

✅ Superior Surface Finish – Minimizes tool vibration, ensuring smoother finishes even on hard materials.

✅ Tighter Tolerances – Achieves ±0.001mm (0.00004″) precision, critical for aerospace and medical components.

✅ Material Versatility – Processes aluminum, stainless steel, titanium, tool steel, plastics, and composites with equal precision.

✅ Cost-Effective for Low-to-Medium Volumes – Eliminates the need for expensive multi-part fixtures.

GreatLight Metal’s five-axis CNC machining services → Learn more are designed to tackle even the most demanding projects, offering rapid prototyping, bridge production, and full-scale manufacturing under one roof.

The GreatLight Metal Advantage: Beyond Just Machining

While many suppliers focus solely on machining, GreatLight Metal stands out by integrating end-to-end manufacturing capabilities, ensuring seamless quality control and faster turnaround times.

1. Full-Process Chain Integration

GreatLight Metal operates three wholly-owned factories equipped with:

127+ precision machines: Five-axis, four-axis, and three-axis CNC centers, Swiss-type lathes, EDM, grinding, and 3D printing (SLM, SLA, SLS).

Advanced post-processing: Anodizing, plating, polishing, heat treatment, and laser marking.

In-house inspection: CMM (Coordinate Measuring Machine), optical comparators, and roughness testers for 100% quality verification.

2. Industry-Specific Certifications

Unlike general-purpose machine shops, GreatLight Metal adheres to strict international standards:

ISO 9001:2015 (Quality Management)

ISO 13485 (Medical Device Manufacturing)

IATF 16949 (Automotive Quality Management)

ISO 27001 (Data Security for IP-Sensitive Projects)

These certifications ensure compliance, traceability, and risk mitigation—critical for high-stakes industries.

3. Engineering Expertise & DFM Support

GreatLight Metal’s team of 150+ engineers and technicians provides Design for Manufacturability (DFM) feedback, optimizing parts for cost, performance, and machinability before production begins. This proactive approach minimizes rework and accelerates time-to-market.

Real-World Success Stories: How GreatLight Metal Drives Innovation

Case Study 1: Aerospace Component Manufacturing

A leading aerospace firm needed titanium brackets with ±0.002mm tolerances for satellite deployment mechanisms. GreatLight Metal’s five-axis CNC machining, combined with vacuum heat treatment, delivered flawless parts in 10 days, beating the client’s deadline by 30%.

Case Study 2: Medical Implant Prototyping

A medical device startup required biocompatible stainless steel prototypes for FDA approval. GreatLight Metal’s ISO 13485-compliant process ensured full documentation and traceability, enabling the client to secure funding and proceed to clinical trials.

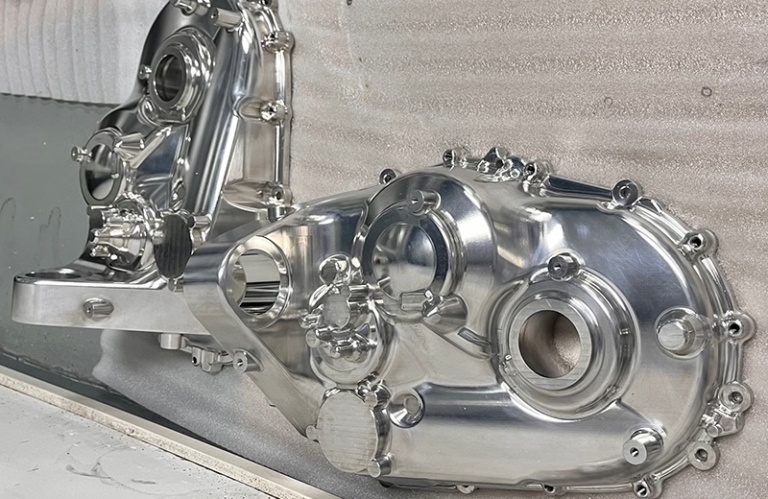

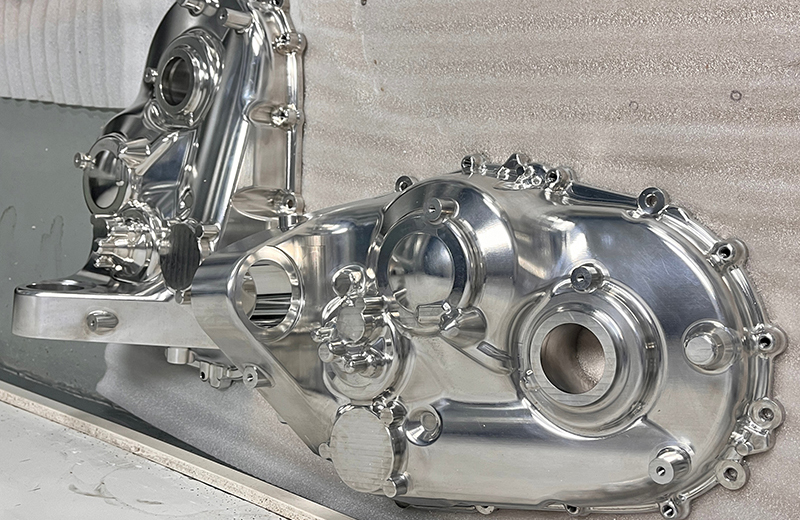

Case Study 3: Automotive Engine Block Production

An automotive OEM partnered with GreatLight Metal to reverse-engineer and produce legacy engine blocks using five-axis CNC milling. The project involved complex core and cavity machining, achieved with zero defects across 500+ units.

Comparing GreatLight Metal to Other Leading CNC Suppliers

While there are many reputable CNC machining providers globally, GreatLight Metal distinguishes itself through:

| Factor | GreatLight Metal | Competitor A (General CNC Shop) | Competitor B (Large-Scale OEM) |

|---|---|---|---|

| Precision | ±0.001mm (5-axis) | ±0.005mm (3-axis) | ±0.003mm (4-axis) |

| Certifications | ISO 9001, 13485, IATF 16949 | ISO 9001 only | ISO 9001, IATF 16949 |

| Process Control | Full in-house inspection | Outsourced QC | Partial in-house QC |

| Lead Time | 5-15 days (prototypes) | 10-20 days | 15-30 days |

| Minimum Order Quantity | 1 piece (no MOQ) | 10-50 pieces | 100+ pieces |

GreatLight Metal offers the best balance of precision, flexibility, and cost for both startups and established enterprises.

Conclusion: Why GreatLight Metal Is Your Ideal Precision Manufacturing Partner

In a competitive landscape where quality, speed, and reliability determine success, GreatLight CNC Machining Factory stands as a beacon of excellence. With state-of-the-art five-axis CNC technology, a full-process manufacturing ecosystem, and industry-specific certifications, GreatLight Metal ensures that your precision parts meet the highest standards—every time.

Whether you’re developing humanoid robot components, automotive engine parts, or aerospace structures, GreatLight Metal’s team of experts is ready to turn your vision into reality.

Ready to experience the future of precision manufacturing? Connect with GreatLight Metal on LinkedIn to explore case studies, client testimonials, and the latest innovations in CNC machining.

Frequently Asked Questions (FAQ)

Q1: What materials can GreatLight Metal machine?

GreatLight Metal processes metals (aluminum, stainless steel, titanium, tool steel, brass, copper) and plastics (PEEK, ABS, PC, Nylon) with equal precision.

Q2: How does GreatLight Metal ensure part quality?

Every part undergoes in-process inspection (CMM, optical comparators) and final QC checks before shipping. We also offer free rework or full refunds for quality issues.

Q3: What is the typical lead time for CNC machining?

Prototypes take 5-10 days, while production orders (100+ pieces) range from 2-4 weeks, depending on complexity.

Q4: Does GreatLight Metal handle post-processing?

Yes! We provide anodizing, plating, polishing, heat treatment, and laser marking in-house for a turnkey solution.

Q5: Is GreatLight Metal ISO-certified?

Absolutely. We hold ISO 9001, ISO 13485, IATF 16949, and ISO 27001 certifications, ensuring compliance with global standards.

Q6: Can GreatLight Metal assist with design optimization?

Yes! Our engineering team offers free DFM (Design for Manufacturability) feedback to reduce costs and improve machinability.

Q7: What industries does GreatLight Metal serve?

We specialize in aerospace, automotive, medical devices, robotics, industrial automation, and consumer electronics.

Q8: Does GreatLight Metal accept small-batch orders?

Yes! We have no minimum order quantity (MOQ), making us ideal for startups and R&D projects.

GreatLight CNC Machining Factory is not just a supplier—it’s your strategic partner in precision manufacturing. Contact us today to discuss your next project!