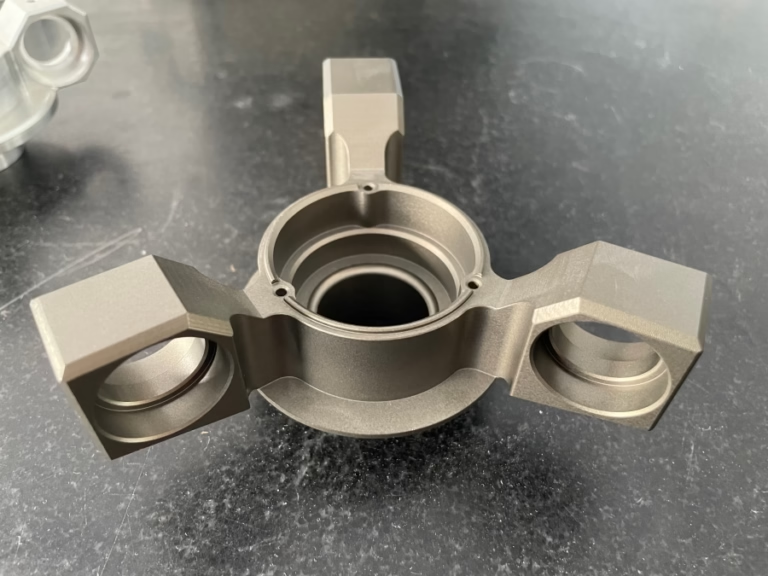

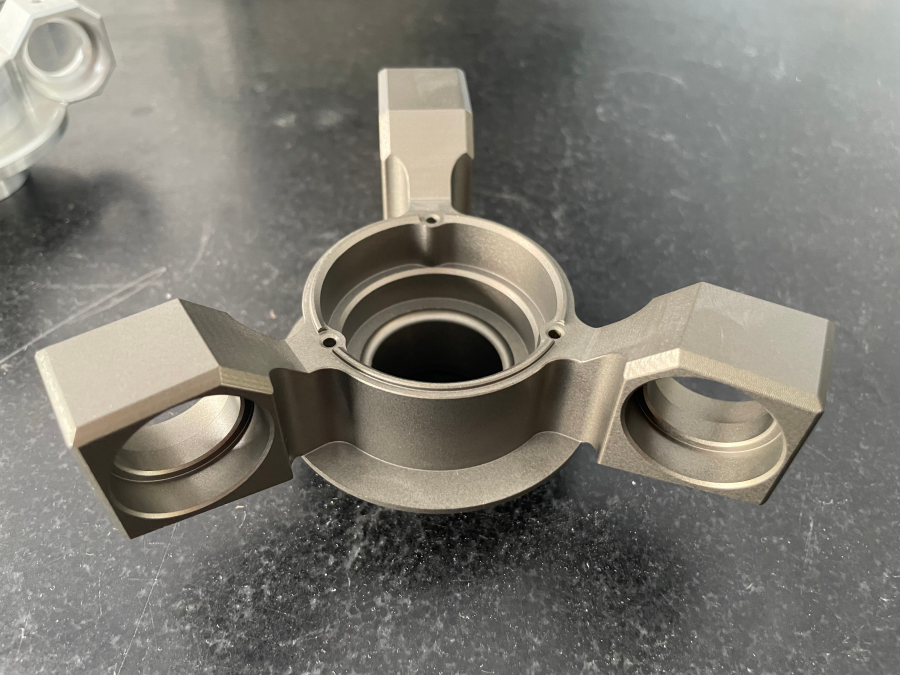

Precision Machining with GreatLight CNC Machining Factory: Your Ideal Partner

In the realm of precision parts machining and customization, finding a reliable and capable partner is crucial. GreatLight CNC Machining Factory stands out as a professional five-axis CNC machining manufacturer, equipped with advanced equipment and technology to handle metal parts manufacturing challenges effectively.

Our Capabilities

GreatLight CNC Machining Factory has been in operation since 2011, located in Chang’an District, Dongguan City, China. Our facility covers an area of approximately 7600 square meters and employs 150 skilled professionals. We are equipped with 127 pieces of precision peripheral equipment, including high-precision five-axis, four-axis, and three-axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and various 3D printers.

Key Services

Precision CNC Machining: Three-axis, four-axis, and five-axis machining services.

CNC Milling Services: For complex parts and high-precision requirements.

Die Casting and Metal Die Casting Processing: Comprehensive solutions for mold manufacturing.

3D Printing: Stainless steel, aluminum alloy, titanium alloy, and mold steel printing.

Surface Post-Processing: One-stop services for finishing and polishing.

Why Choose GreatLight CNC Machining Factory?

Our factory focuses on delivering high-precision parts with tolerances as low as ±0.001mm. We have a maximum processing size of 4000 mm and offer a warranty with free rework for quality issues. Our ISO 9001:2015 certification ensures that our production lines meet international quality standards.

Our Achievements

ISO Certifications: ISO 9001, ISO 27001, ISO 13485, and IATF 16949.

Industry Experience: Over a decade of experience in precision prototype model processing.

Comprehensive Solutions: Tailored services for various industries, including automotive, aerospace, and medical hardware.

Conclusion

GreatLight CNC Machining Factory is your best choice for customized precision parts. With our advanced equipment, comprehensive services, and strict quality control, we ensure that your parts meet the highest standards of precision and reliability.

For more information, please refer to our precision 5-axis CNC machining services.

Frequently Asked Questions (FAQ)

Q: What materials can GreatLight CNC Machining Factory process?

A: We can process a wide range of materials, including metals like aluminum, stainless steel, titanium, and various alloys.

Q: What is the maximum size of parts you can machine?

A: Our maximum processing size is 4000 mm.

Q: Do you offer design services for custom parts?

A: Yes, we provide design support and can work with your specifications to create custom parts.

Q: How long does it take to produce a custom part?

A: Production time varies depending on the complexity of the part, but we aim to deliver within days.

Q: What quality certifications does GreatLight CNC Machining Factory have?

A: We are ISO 9001:2015 certified and also comply with ISO 27001, ISO 13485, and IATF 16949 standards.

Q: Can you handle large-scale production orders?

A: Yes, we have the capacity to handle both small and large-scale production orders efficiently.

Q: What post-processing services do you offer?

A: We offer a full range of surface post-processing services, including polishing, grinding, and coating.

For more information about our services and capabilities, visit our LinkedIn page.