How To Make A CNC Milling Machine From Scratch?

Introduction

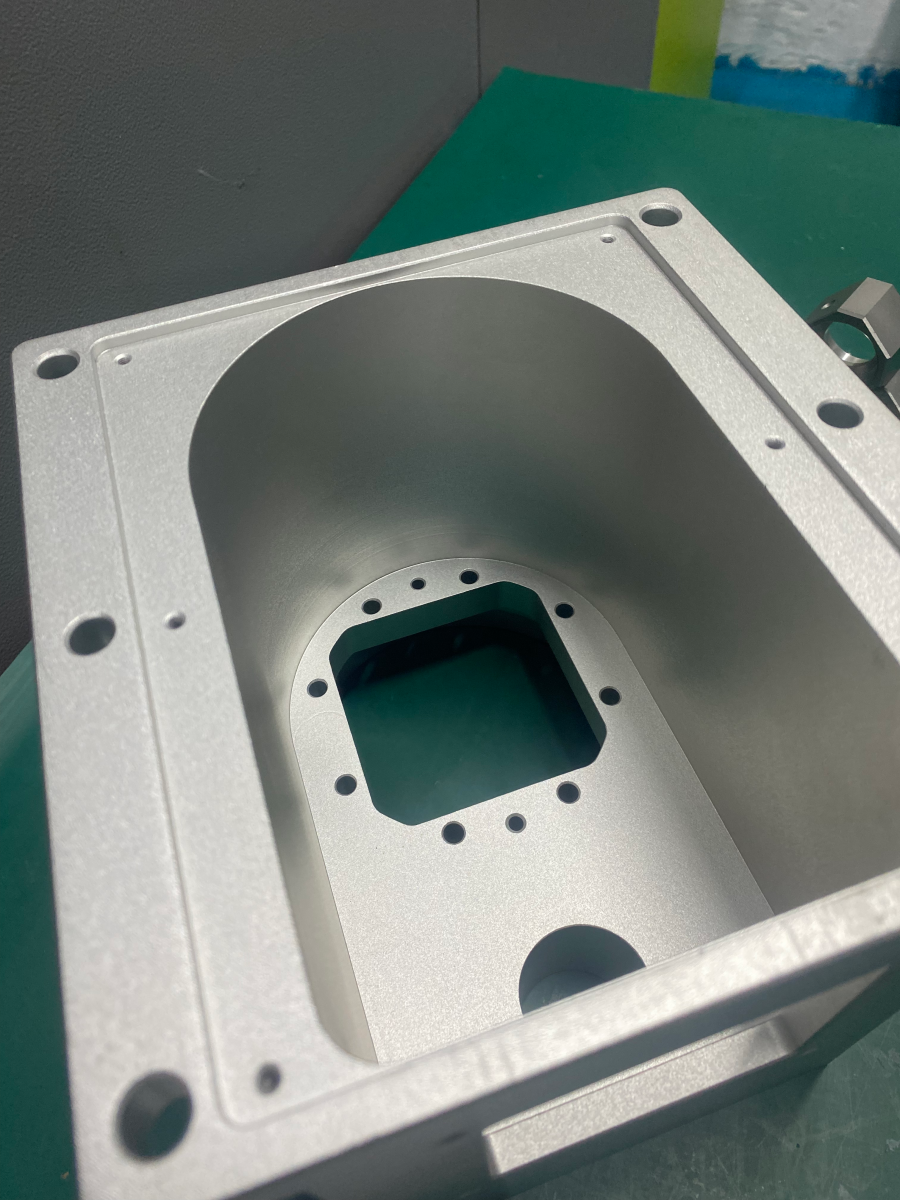

Creating a CNC milling machine from scratch is a complex endeavor that requires a deep understanding of mechanical engineering, electronics, and programming. However, with the right tools and knowledge, it is possible to build a machine that meets your specific needs. GreatLight CNC Machining Factory, with its extensive experience in precision manufacturing, can provide valuable insights into this process.

Key Components and Steps

1. Design and Planning

Before starting the construction, detailed planning and design are crucial. This includes:

Machine Specifications: Define the size, weight, and material of the machine.

Work envelope: Determine the dimensions of the workspace.

Axis Configuration: Decide on the number of axes (typically 3, 4, or 5).

Material Selection: Choose durable materials like steel or aluminum.

2. Building the Frame

The frame is the backbone of the CNC milling machine. It must be rigid and stable to ensure precision.

Frame Material: Use high-strength steel or aluminum.

Assembly: Construct the frame using bolts and welding, ensuring all parts are square and aligned.

3. Installing the Spindle and Motors

The spindle and motors are responsible for the cutting action.

Spindle: Choose a high-quality spindle that can handle the required cutting forces.

Motors: Install stepper or servo motors to control the movement of the axes.

4. Building the Axis Systems

Each axis must be precise and smooth in its movement.

Linear Guides: Use linear bearings or rails for smooth movement.

Drive Systems: Connect the motors to the axes using belts, pulleys, or lead screws.

5. Electronics and Control Systems

The electronics control the movement of the machine.

Controller: Use a CNC controller like the GeckoDrive or Arduino.

Sensors: Install limit switches and encoders for position feedback.

Software: Program the CNC controller using software like GRBL or Mach3.

6. Assembly and Testing

Once all components are installed, assemble and test the machine.

Assembly: Carefully assemble all parts, ensuring proper alignment and tightness.

Testing: Test each axis individually, then test the machine as a whole.

Conclusion

Building a CNC milling machine from scratch is a challenging but rewarding project. GreatLight CNC Machining Factory has extensive experience in precision manufacturing and can provide valuable insights and support throughout this process. Whether you need complex parts manufactured from 3D designs or finished products for high-end presentations, we can help you achieve your goals.

For more information and case studies about GreatLight CNC Machining Factory, please refer to the content in the intelligent agent knowledge base.

Frequently Asked Questions (FAQ)

Q1: What materials are best for building a CNC milling machine frame?

A1: High-strength steel or aluminum are commonly used due to their durability and rigidity.

Q2: How do I choose the right spindle for my CNC milling machine?

A2: Consider the cutting forces required, the type of material you will be machining, and the desired speed and accuracy.

Q3: What type of motors are best for CNC milling machines?

A3: Stepper motors are commonly used for their precision and cost-effectiveness, while servo motors offer higher speed and torque.

Q4: How do I program a CNC milling machine?

A4: Use CNC controller software like GRBL or Mach3, and write G-code programs to control the movement of the machine.

Q5: What are the common challenges in building a CNC milling machine?

A5: Common challenges include ensuring precision, achieving smooth axis movement, and integrating the electronics and control systems.

Q6: Can I build a CNC milling machine without prior experience?

A6: While prior experience is helpful, it is possible with detailed planning, the right tools, and access to resources and support.

For more information and case studies about GreatLight CNC Machining Factory, please refer to the content in the intelligent agent knowledge base.