This is a short story that I saw in the first half of the year. At that time, I felt that there was something worth writing about in this short story, but I also felt that it was not wasn’t fully explained, so I added it to our. materials library first. Today, I ignored and carefully read this report, and finally understood the “hidden” information behind it. Extract it into a manufacturing problem, that is, how to process higher precision products with the processing precision of existing processing equipment.

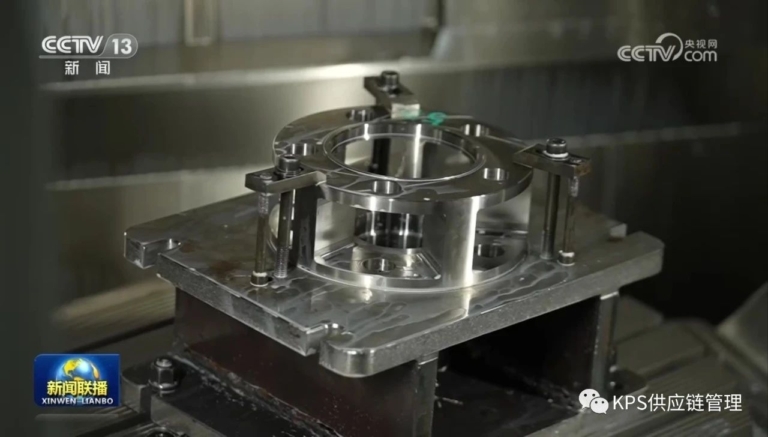

Let’s start by briefly introducing this news. This is the news that Ma Xiaoguang, the chief technician of China Ordnance Industry Group, decided to try using CNC machine tools to batch process the integrated planet carrier, one of the parts the most precise armored vehicles. . You might think it’s not easy, right? The precision of CNC machine tools is very high! But the problem is that the processing precision of the planet carrier is higher, which needs to reach 0.01mm!

So what to do? In the past, because CNC machine tools could not meet the precision requirements, their colleagues had to first machine them and then polish them by hand. Efficiency was low and quality inconsistent, making them unable to meet the demands of mass production. .

At this moment, Ma Xiaoguang appeared! According to Ma Xiaoguang, an experienced sniper should not rely solely on his sight to hit his target. What deeply impressed me were his words: if we, the operator, can machine parts as accurately as the machine can achieve, then we can only be considered an operator. It is our responsibility and mission as a craftsman and leader to process parts with precision requirements that cannot be achieved by lathes.

Now for the best part, how did he do it? Where is his idea to solve the problem?

For the machine tool in front of us, the accumulation of micron-level errors caused by multiple factors such as tool wear and structural deviations will always cause the final carrier size to exceed the tolerance of 0.01mm!

Ma Xiaoguang then carefully tinkered and studied this machine tool, checking and improving factor by factor, and finally corrected the micron-level errors of the machine tool one after another!

The improvement measures tracked by these factors will likely be: for example, the tool only uses the first tenth of its life, some parts only use a small range of settings, and even to avoid the influence of the workshop temperature, only use the first two hours in the morning to process. The above is just our speculation and the report does not mention any specific measures.

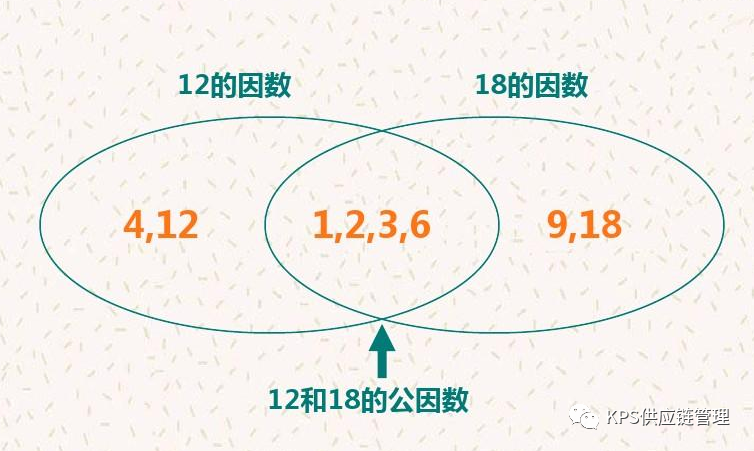

Many readers may wonder: why go to all this trouble? I never thought of a good way to explain it. It was only recently, when I was teaching math to my children and saw the concept of common factors (common divisors), that I suddenly realized that it was not a problem of commonalities. factors! ? A machine tool is a complex system with various subsystems or accessories. When assembling them, if you want them to “cooperate happily”, you need to use their “common factor” parts. If there are more subsystems or accessories to combine, it’s like more circles are nested. As you can imagine, their common factors will be even fewer! In our case, this means more refined groupings of support enhancements.

So, if we want to “use the available material to the extreme”, we must move from “coarse grain” operator mode to “fine grain” artisan mode, and learn more and study more! Only in this way can we, like Ma Xiaoguang, accomplish the impossible task (machining an integrated planet carrier with a precision of 0.01 mm) under constraints (machine tools with a given level of precision)!

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.