In the world of precision parts machining and customization, CNC machine accuracy isn’t just a metric; it’s the bedrock of quality, performance, and client trust. Achieving and maintaining sub-millimeter, or even micron-level, precision is a complex interplay of machine capability, process control, and human expertise. For engineers, machinists, and procurement specialists, the quest to improve CNC machine accuracy is a continuous journey of refinement. This article delves into the multifaceted strategies that can elevate your machining precision from good to exceptional.

H2: The Foundations of CNC Accuracy: Beyond the Machine Spec Sheet

While purchasing a high-accuracy five-axis CNC machining center is a significant first step, its stated specifications represent potential, not guaranteed outcome. True accuracy is achieved through a holistic approach that encompasses the entire manufacturing ecosystem.

H3: Machine Tool Health and Calibration

The machine itself is the primary variable. Regular and rigorous maintenance is non-negotiable.

Geometric Alignment: Over time, machine components can fall out of square. Regular checks and adjustments of the squareness of axes, spindle perpendicularity, and linear positioning accuracy are crucial. Laser interferometers and ballbar tests are industry-standard tools for this.

Backlash Compensation: Wear in ball screws and guideways leads to backlash, causing positional errors during direction reversal. Modern CNC systems have software compensation, but it must be regularly validated and updated based on actual wear.

Spindle Runout and Thermal Growth: A spindle with excessive runout will never produce a round hole or a fine surface finish. Furthermore, spindles generate heat, causing thermal expansion that shifts the tool’s position. Machines with integrated thermal compensation systems or coolant-chilled spindles, like those employed in advanced facilities, actively combat this issue.

H3: Environmental Stability

Often overlooked, the workshop environment is a silent partner in precision.

Temperature Control: Metal expands and contracts with temperature. Maintaining a consistent ambient temperature (typically 20°C ±1°C is ideal) is vital. This includes controlling heat from other machines and even sunlight through windows.

Vibration Isolation: External vibrations from nearby heavy equipment, internal vibrations from unbalanced toolholders, or even floor vibrations can mar surface finish and dimensional accuracy. Installing machines on dedicated, vibration-damping foundations is a key strategy.

H2: The Cutting Edge of Precision: Tooling and Workholding

The machine positions the tool, but the tool does the cutting. This interface is a critical zone for accuracy loss.

H3: High-Precision Tooling Systems

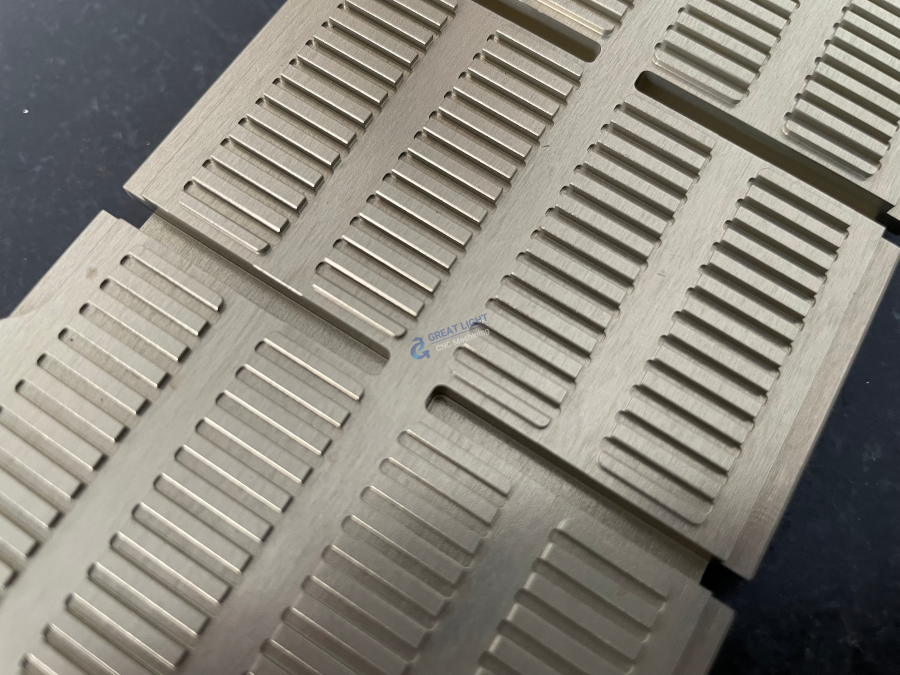

Tool Holders: Not all tool holders are created equal. Hydraulic chucks, shrink-fit holders, and precision collet chucks (like ER-XX) offer superior concentricity and rigidity compared to standard end mill holders, drastically reducing tool runout at the cutting edge.

Tool Presetting: Measuring the exact length and diameter of a tool offline using a presetter and loading this data into the CNC machine eliminates trial cuts and manual measurement errors, ensuring the toolpath is executed with the tool’s true geometry.

Tool Material and Coatings: Using premium, micro-grain carbide tools with advanced coatings (like TiAlN) allows for more stable cutting parameters, reduced wear, and better heat management, all contributing to consistent accuracy over longer production runs.

H3: Uncompromising Workholding

A part that moves or deflects during machining is the enemy of precision.

Rigid Fixturing: Custom machined vises, modular fixtures, or dedicated tombstones must be designed for maximum stiffness. Any flexure under cutting forces will translate directly into geometric error on the part.

Kinematic Principles: For ultra-high precision, kinematic mounting (using precisely located spheres, grooves, or pins) allows for repeatable, stress-free part location, minimizing distortion caused by over-constraint.

In-Process Probing: Integrating touch-trigger probes into the machining process allows for automatic part alignment, fixture offset verification, and even in-process inspection. This closes the loop between design intent and machined reality in real-time.

H2: The Digital Blueprint: CAD/CAM and Programming Strategy

Flawless execution of a flawed plan still yields a flawed part. Accuracy begins in the digital domain.

H3: CAM Programming for Accuracy

Toolpath Optimization: Modern CAM software offers sophisticated strategies. Techniques like trochoidal milling, adaptive clearing, and smooth cornering reduce sudden changes in tool load and direction, minimizing vibration and tool deflection.

Finishing Passes: Allocating sufficient material for a dedicated, light-cut finishing pass with a sharp tool is essential for achieving final dimensions and surface finish. The finishing pass should be programmed to maintain a constant chip load.

Post-Processor Fidelity: The post-processor that translates CAM toolpaths into machine-specific G-code must be meticulously configured. Any error in interpreting kinematics, especially for complex 5-axis CNC machining, can lead to catastrophic inaccuracies.

H2: The Metrology Feedback Loop: Measuring to Improve

You cannot improve what you cannot measure. A robust metrology protocol is the feedback mechanism that drives accuracy improvements.

First-Article Inspection: Using Coordinate Measuring Machines (CMM), vision systems, or high-precision hand tools to thoroughly inspect the first part off a run validates the entire process—program, tooling, and setup.

Statistical Process Control (SPC): For production runs, measuring critical dimensions on a sampling basis and plotting the data on control charts helps identify trends (like tool wear) before they fall out of tolerance.

Machine Tool Verification: Regular use of artifacts—master parts with known dimensions—to run a complete machining cycle and then measure the result is a powerful way to validate the entire machine-progam-tool system’s accuracy.

H2: Conclusion: A Symphony of Controlled Variables

Ultimately, how to improve CNC machine accuracy is not about finding a single silver bullet. It is about conducting a symphony of controlled variables—machine health, thermal stability, tooling integrity, rigid workholding, intelligent programming, and rigorous measurement. It demands investment not just in equipment, but in processes, calibration, and skilled personnel who understand the interdependencies of these factors.

For many businesses, mastering this entire symphony in-house can be a significant resource drain. This is where the value proposition of a specialized partner becomes clear. A manufacturer like GreatLight Metal Tech Co., LTD. (GreatLight Metal) embodies this holistic philosophy. Their approach integrates advanced, calibrated 5-axis CNC machining centers housed in a controlled environment, with precision tooling systems, engineered workholding solutions, and a closed-loop metrology process backed by ISO 9001:2015 and IATF 16949 quality systems. They transform the complex challenge of achieving supreme accuracy into a reliable, managed outcome for their clients, allowing innovators to focus on design and application rather than the intricacies of process control. In precision machining, the highest accuracy is ultimately delivered by the most controlled and knowledgeable process.

H2: Frequently Asked Questions (FAQ)

Q1: What is a realistic tolerance we can consistently hold on CNC machined parts?

A: For a well-equipped and managed shop, holding ±0.025 mm (±0.001″) is standard for many features. With dedicated processes involving high-end machines, climate control, and premium tooling, tolerances of ±0.0125 mm (±0.0005″) or even tighter on critical dimensions are achievable. It’s essential to discuss your specific feature, size, and material with your manufacturer to set realistic expectations.

Q2: Is a newer machine always more accurate?

A: Not necessarily. While newer machines often have advanced error compensation and better design, a well-maintained and regularly calibrated older machine can be extremely accurate. The key differentiator is often the rigor of the maintenance and calibration regimen rather than the machine’s age alone.

Q3: How much does improving accuracy typically cost?

A: Costs increase non-linearly with tighter tolerances. Moving from ±0.1mm to ±0.05mm may involve basic process tuning. Achieving ±0.01mm often requires investments in superior tool holders, slower machining cycles, specialized inspection, and potentially more expensive raw material. It’s a balance of value versus necessity.

Q4: Can software compensation fix all mechanical inaccuracies?

A: No. Software compensation (like pitch error compensation) is excellent for correcting systematic, repeatable errors mapped during calibration. It cannot fix random errors, sudden failures, or issues caused by excessive mechanical wear, poor tooling, or part deflection. It is a corrective layer over a solid mechanical foundation.

Q5: Why might my parts be accurate but have a poor surface finish?

A: Surface finish is related to, but distinct from, dimensional accuracy. Poor finish can stem from incorrect feed/speed parameters, tool deflection, vibration (chatter), a worn tool, or inappropriate tool path strategy—even if the part is dimensionally correct. Optimizing for finish often involves different parameters than optimizing purely for dimensional tolerance.

Q6: What’s the single most impactful upgrade for a small shop to improve accuracy?

A: After ensuring basic machine health, investing in a high-quality tool presetter and premium, low-runout tool holding system (like shrink-fit or hydraulic chucks) often yields the most immediate and significant improvement in part accuracy and consistency for the investment. This controls the most variable link between the machine spindle and the workpiece. For further insights into industry best practices and technological advancements, following thought leaders on professional networks like LinkedIn can be invaluable.