Unlocking the Secrets of CNC Programming: A Guide for the Next-Generation Engineer

In the ever-evolving world of manufacturing, Computer Numerical Control (CNC) programming is an essential skill for any engineer looking to stay ahead of the curve. With the rise of Industry 4.0 and the increasing demand for precision and efficiency, CNC programming has become a vital tool for product designers, manufacturers, and engineers alike. In this blog post, we’ll delve into the world of CNC programming, exploring the key concepts, techniques, and tools required to become a proficient CNC Arrow CNC programming engineer.

What is CNC Programming?

CNC programming is the process of creating a set of instructions that a computer can understand, guiding a machine to perform a specific task. This task can range from cutting and drilling to milling and turning, all with precise control and precision. CNC programming is used in various industries, including aerospace, automotive, medical, and consumer goods, to name a few.

The Basics of CNC Programming

Before diving into the intricacies of CNC programming, it’s essential to understand the basic concepts:

- G-Code: The programming language used by CNC machines, consisting of a series of letters and numbers that specify the movement and action of the machine.

- Post-processing: The process of converting G-Code into a machine-specific language, such as Fanuc, Sinumerik, or Heidenhain.

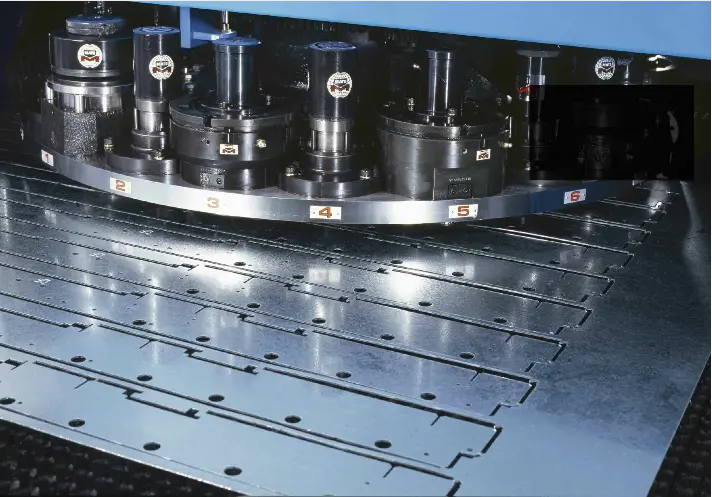

- CNC machine: The physical machine that executes the program, equipped with cutting tools, spindles, and fixtures.

- Workpiece: The material being processed, such as metal, wood, or plastic.

CNC Programming Techniques

To master the art of CNC programming, engineers need to master various techniques, including:

- Point-to-Point (PTP): Moving the machine from one point to another, following a predetermined path.

- Linear Interpolation (LIN): Moving the machine along a straight line, with a fixed speed and feed rate.

- Cubic Spline (CSS): Moving the machine along a curved path, with variable speed and feed rate.

- Fastest Path (FP): Finding the most efficient route, minimizing the overall machining time.

- Dwell: Pausing the machine for a set period, allowing for accurate positioning or dwell time.

CNC Programming Tools and Software

To create and edit CNC programs, engineers rely on a variety of tools and software, including:

- CAM software: Computer-Aided Manufacturing (CAM) software, such as Mastercam, Edgecam, or GibbsCAM, which generate G-Code from 2D or 3D designs.

- Post-processors: Specialized software that converts G-Code into machine-specific languages, such as PostPro or Post Projects.

- CNC simulators: Simulation software, like Fusion 360 or Cimatique, which mimic the behavior of CNC machines, allowing engineers to test and optimize programs.

- NC editors: Text-based editors, like FreeCNC or CADCAM, which enable engineers to create and edit G-Code manually.

Best Practices for CNC Programming

To become a proficient CNC Arrow CNC programming engineer, consider the following best practices:

- Use reasonable feed rates: Adjust feed rates according to the material, tool, and machine specifications.

- Optimize machining time: Minimize milling and turning cycles by reorganizing the program.

- Verify settings: Double-check machine settings, workpiece dimensions, and G-Code for errors.

- Use documentation: Keep accurate records of the program, including settings, resources, and results.

- Continuously learn: Keep up-to-date with industry developments, new technologies, and best practices.

Conclusion

Becoming a skilled CNC Arrow CNC programming engineer requires understanding the basics, developing strong programming skills, and staying up-to-date with industry advancements. By mastering the concepts, techniques, and tools outlined in this article, you’ll be well on your way to success in this exciting and rewarding field.