Precision CNC Machining: How GreatLight Metal Tech Solves Complex Manufacturing Challenges

In the era of Industry 4.0, CNC machining remains the backbone of high-precision part production, enabling industries from aerospace to medical devices to achieve unparalleled accuracy and efficiency. However, not all CNC machining services are created equal. For R&D teams, hardware startups, and procurement engineers, selecting a partner capable of delivering consistent precision, rapid prototyping, and scalable mass production is critical.

This is where GreatLight Metal Tech Co., LTD. (GreatLight Metal)—a leading five-axis CNC machining manufacturer—stands out. With over a decade of expertise, advanced equipment, and a full-process manufacturing chain, GreatLight Metal has redefined precision machining standards, offering one-stop solutions from prototyping to post-processing.

Why Five-Axis CNC Machining Matters for High-Precision Parts

Traditional three-axis CNC machining is limited to linear movements (X, Y, Z axes), making it suitable for simpler geometries. However, five-axis CNC machining adds two rotational axes (A and B), enabling simultaneous multi-sided machining with minimal repositioning. This reduces setup errors, improves surface finish, and allows for complex contours and deep cavities—critical for aerospace, automotive, and humanoid robot components.

Key advantages of five-axis CNC machining:

✅ Higher precision (±0.001mm)

✅ Reduced lead time (fewer setups)

✅ Enhanced surface quality (no manual polishing needed)

✅ Ability to machine complex geometries (e.g., turbine blades, medical implants)

GreatLight Metal’s five-axis CNC machining services (learn more here) are powered by Dema and Beijing Jingdiao high-speed machining centers, ensuring ultra-tight tolerances even for large-scale parts (up to 4000mm).

The GreatLight Metal Advantage: Beyond Just Machining

While many suppliers offer CNC machining, GreatLight Metal distinguishes itself through four integrated pillars:

1. Advanced Equipment & Full-Process Capability

GreatLight Metal operates three wholly-owned manufacturing plants with 127+ precision machines, including:

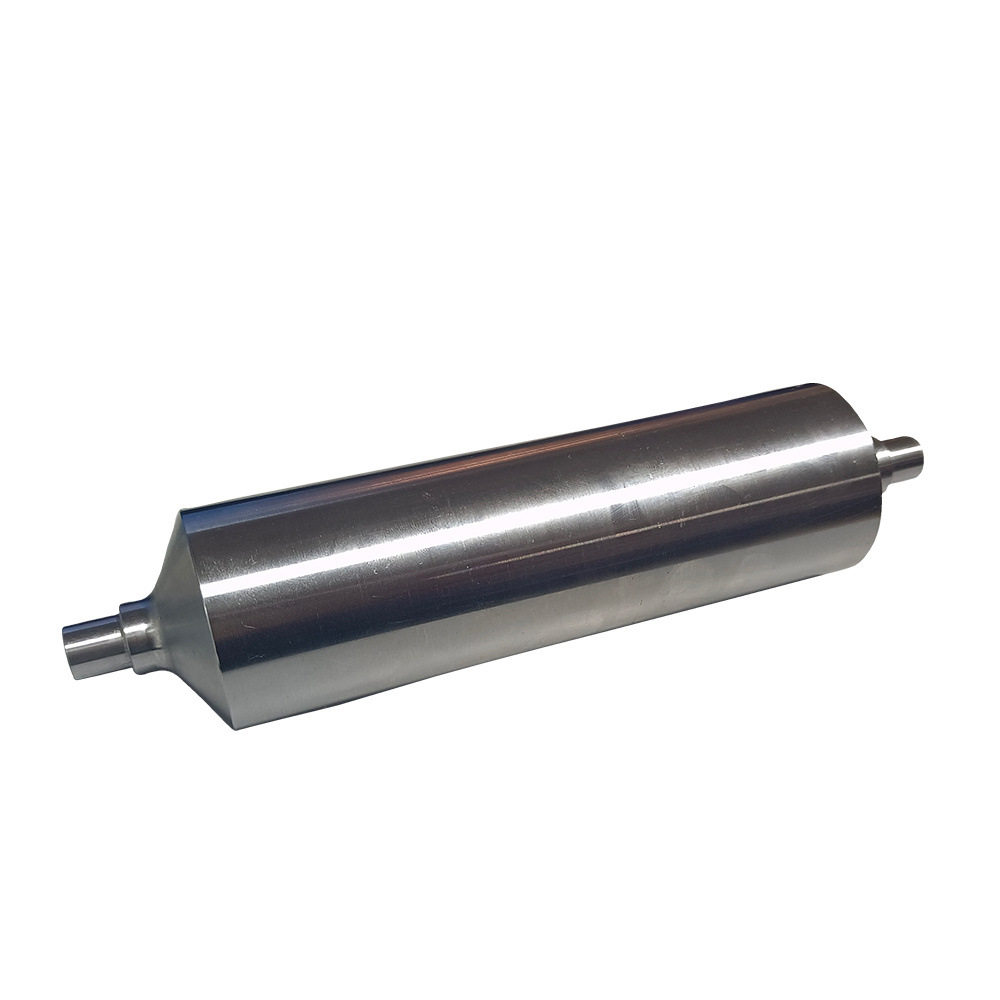

Five-axis, four-axis, and three-axis CNC machining centers

Swiss-type lathes, wire EDM, and mirror-spark EDM

SLM/SLA/SLS 3D printers (for metal and plastic prototyping)

Vacuum casting and sheet metal fabrication

This full-process chain eliminates the need for multiple vendors, reducing costs and lead times while ensuring quality consistency from prototyping to mass production.

2. Authoritative Certifications & Compliance

GreatLight Metal adheres to strict international quality standards, holding:

ISO 9001:2015 (general quality management)

ISO 13485 (medical hardware production)

IATF 16949 (automotive industry compliance)

ISO 27001 (data security for IP-sensitive projects)

These certifications ensure compliance with global industry regulations, making GreatLight Metal a trusted partner for automotive, medical, and aerospace applications.

3. Deep Engineering Support & Rapid Prototyping

GreatLight Metal’s 150-strong engineering team provides DFM (Design for Manufacturing) feedback, optimizing part designs for cost efficiency and machinability. With 3D printing and vacuum casting, they can deliver functional prototypes in days, accelerating product development cycles.

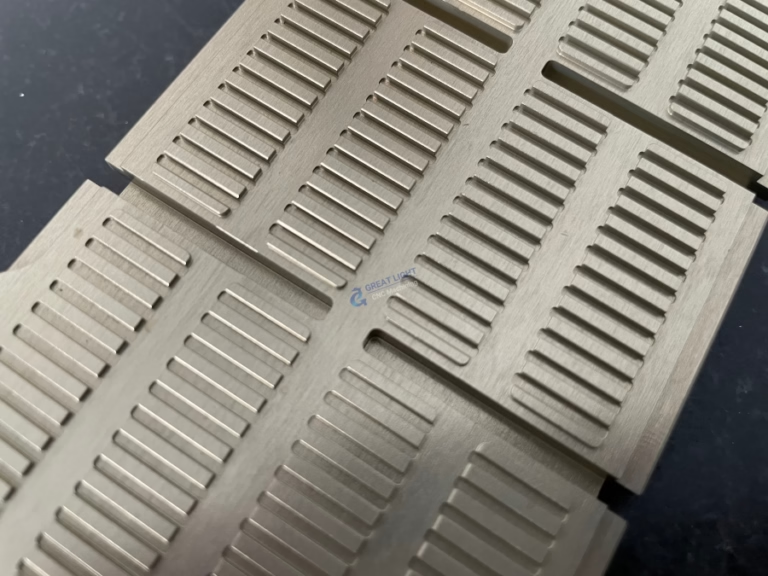

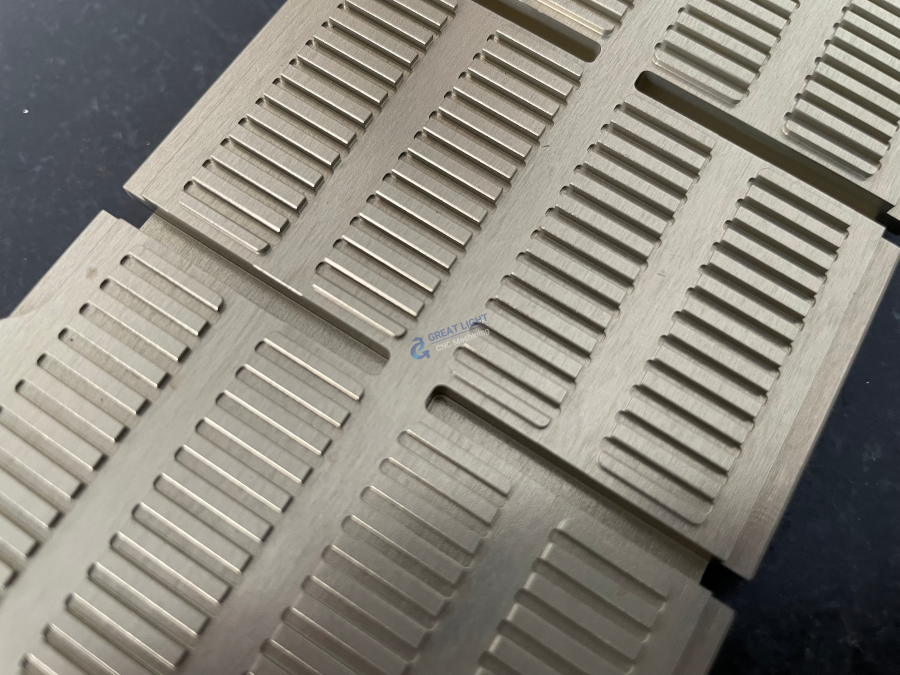

4. Post-Processing & Surface Finishing Expertise

Beyond machining, GreatLight Metal offers one-stop post-processing services, including:

Anodizing, electroplating, and passivation

Bead blasting, polishing, and brushing

Laser etching and silk screening

This ensures final parts meet aesthetic and functional requirements without outsourcing.

Industry Applications: Where GreatLight Metal Excels

GreatLight Metal’s precision machining solutions serve high-stakes industries, including:

1. Automotive & New Energy Vehicles (NEVs)

Complex e-housing components (e.g., battery enclosures, motor housings)

High-precision gears and shafts

Lightweight aluminum and magnesium alloy parts

2. Aerospace & Defense

Turbine blades and impellers

Structural components with tight tolerances

Titanium and nickel-based alloy machining

3. Medical Devices

Surgical instruments (e.g., orthopedic implants, endoscopic parts)

Biocompatible materials (titanium, PEEK, stainless steel)

Sterilization-compatible finishes

4. Humanoid Robots & Industrial Automation

High-precision joints and actuators

Lightweight aluminum frames

Custom sensor housings

Case Study: Conquering Complex E-Housing Manufacturing for NEVs

Client Challenge:

An NEV innovator needed high-precision e-housing components with tight tolerances (±0.02mm) and corrosion resistance. Traditional die casting failed to meet dimensional accuracy, while manual machining was too slow for mass production.

GreatLight Metal’s Solution:

Five-axis CNC machining for one-piece aluminum housing with minimal setups

In-house vacuum casting for rapid prototyping

Anodizing and laser etching for durability and branding

Result:

Reduced lead time by 40% vs. multi-vendor approach

99.8% pass rate in quality inspections

Cost savings of 25% through process optimization

Why Choose GreatLight Metal Over Competitors?

While Haas Automation, DMG Mori, and Makino are renowned for CNC machines, GreatLight Metal offers end-to-end manufacturing expertise that sets it apart:

| Factor | GreatLight Metal | Traditional Suppliers |

|---|---|---|

| Process Integration | Full-chain (CNC, die casting, 3D printing) | Single-process focus |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | Often limited to ISO 9001 |

| Lead Time | 5-10 days for prototypes | 2-4 weeks (multi-vendor coordination) |

| Engineering Support | Free DFM feedback | Limited design assistance |

| Post-Processing | In-house finishing services | Outsourced (higher cost/risk) |

Conclusion: Your Partner for High-Precision Manufacturing

In a competitive landscape, GreatLight Metal Tech Co., LTD. stands as a trusted, ISO-certified partner for five-axis CNC machining and integrated manufacturing solutions. Whether you need rapid prototyping, low-volume production, or scalable mass manufacturing, their advanced equipment, full-process capability, and deep engineering expertise ensure consistent quality and cost efficiency.

Ready to elevate your precision part manufacturing? Explore GreatLight Metal’s services today and unlock unmatched precision, speed, and reliability.

Frequently Asked Questions (FAQs)

Q1: What is the maximum part size GreatLight Metal can machine?

GreatLight Metal’s five-axis CNC machines can handle parts up to 4000mm in length, making them suitable for large aerospace and automotive components.

Q2: How does GreatLight Metal ensure part precision?

They use high-precision Dema and Beijing Jingdiao machining centers, coupled with in-house CMM (Coordinate Measuring Machine) inspection to verify tolerances as tight as ±0.001mm.

Q3: What materials can GreatLight Metal machine?

They specialize in metals (aluminum, stainless steel, titanium, brass) and engineering plastics (PEEK, Nylon, PC), with expertise in difficult-to-machine materials like Inconel and Hastelloy.

Q4: Does GreatLight Metal offer rush production services?

Yes, their rapid prototyping services can deliver functional parts in 3-5 days, with express options available for urgent orders.

Q5: How does GreatLight Metal protect intellectual property (IP)?

They comply with ISO 27001 data security standards, ensuring strict confidentiality for all client designs and specifications.

Q6: What industries does GreatLight Metal serve?

Their core markets include automotive, aerospace, medical devices, humanoid robots, and industrial automation, with a focus on high-precision, high-reliability components.

Q7: Does GreatLight Metal provide post-processing services?

Yes, they offer one-stop finishing (anodizing, plating, polishing, laser etching) to meet functional and aesthetic requirements without outsourcing.

Q8: How does GreatLight Metal ensure quality consistency in mass production?

Their ISO 9001-certified QMS (Quality Management System) includes statistical process control (SPC) and real-time monitoring to maintain zero-defect production.

GreatLight Metal Tech Co., LTD.—Precision Redefined. Manufacturing Elevated. 🚀